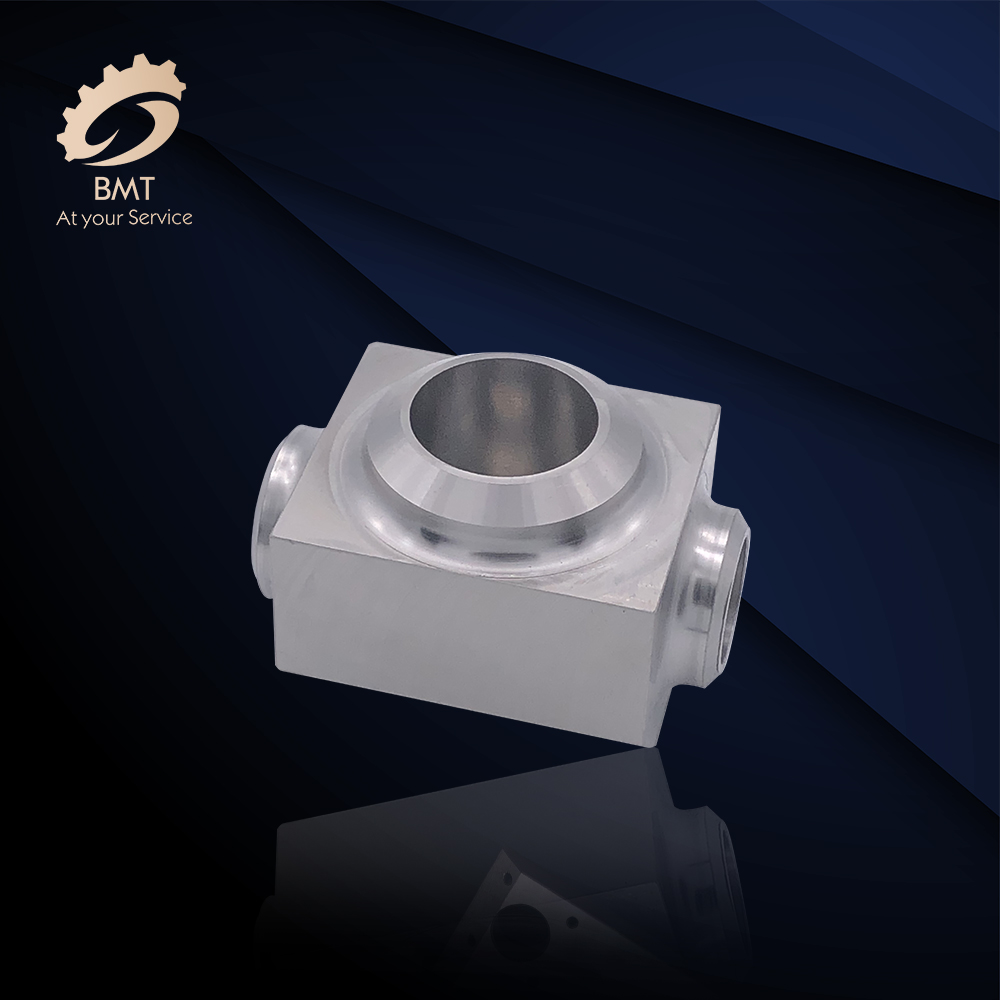

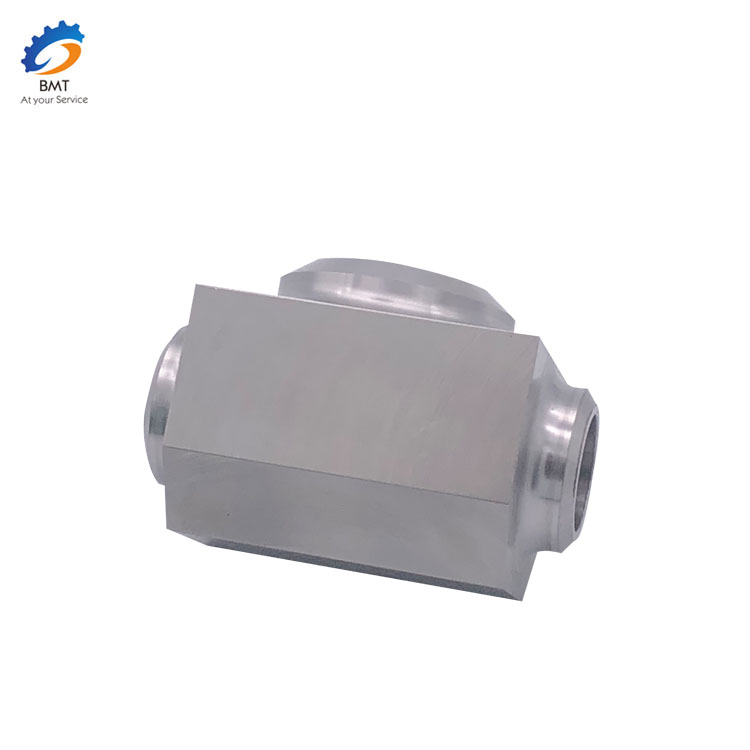

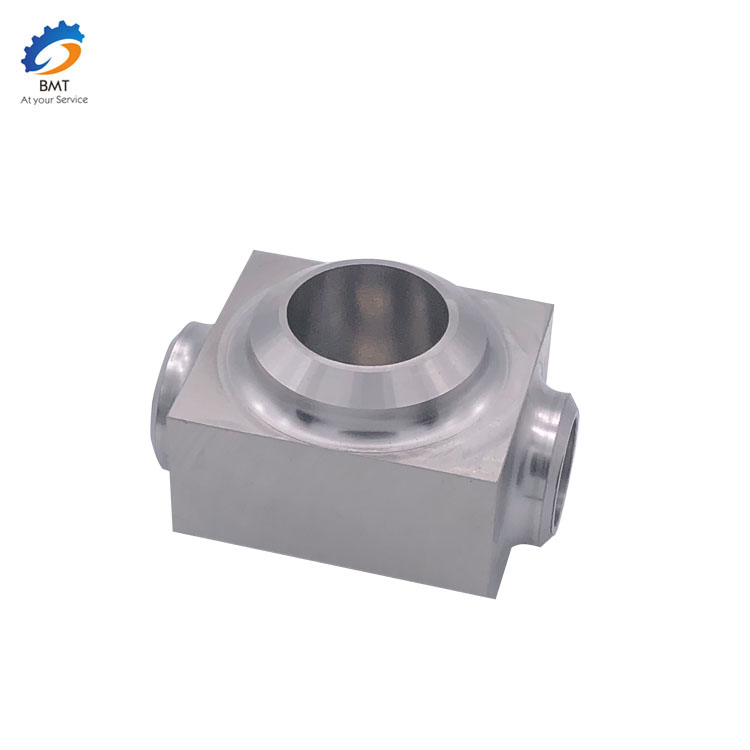

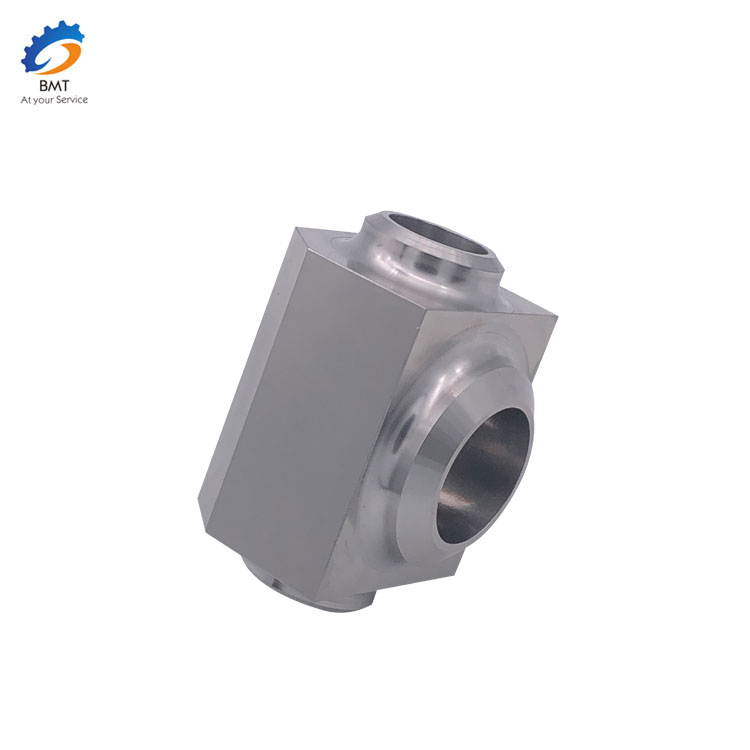

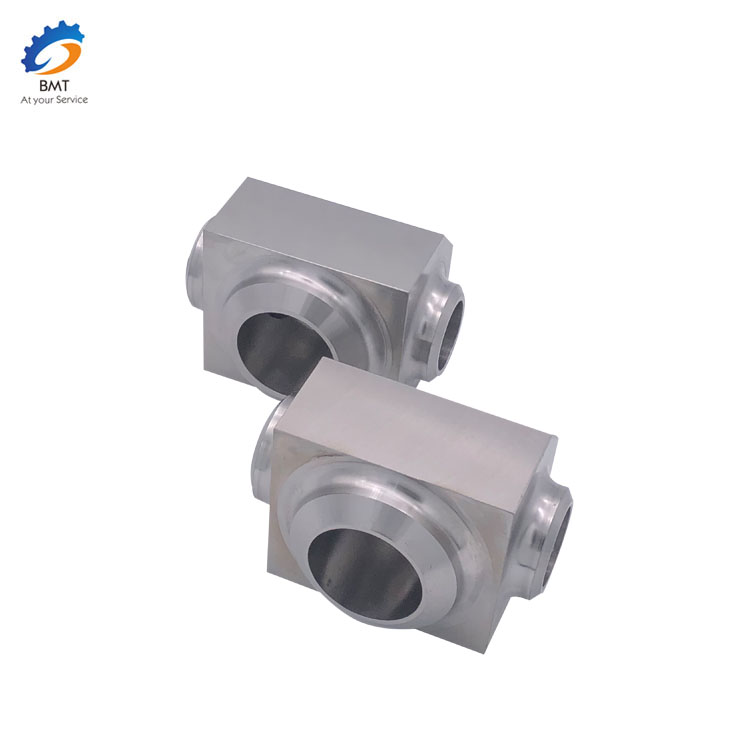

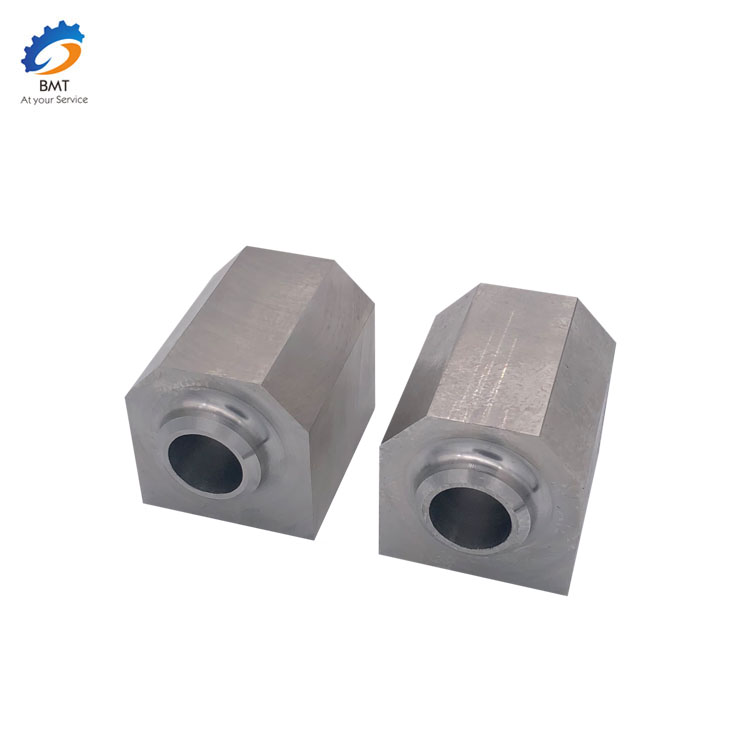

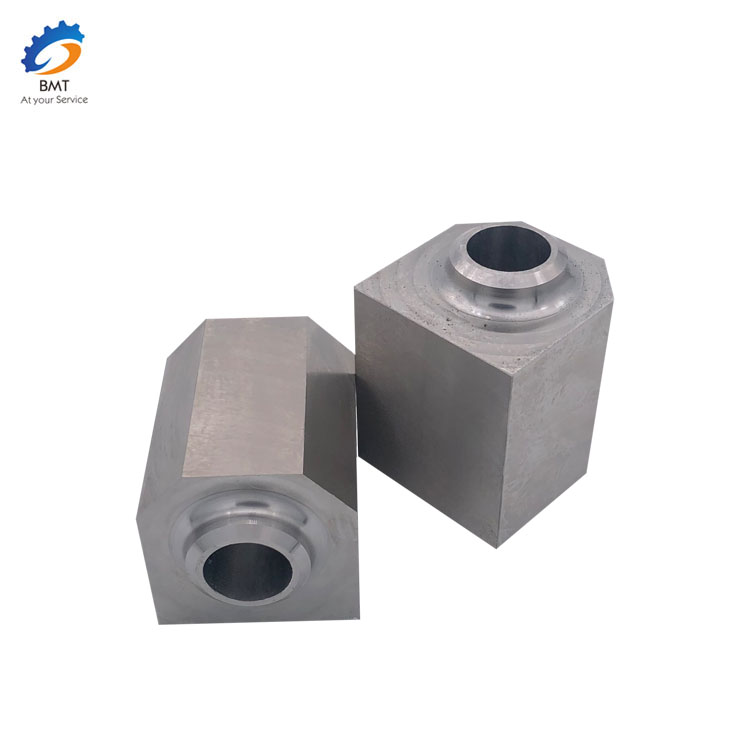

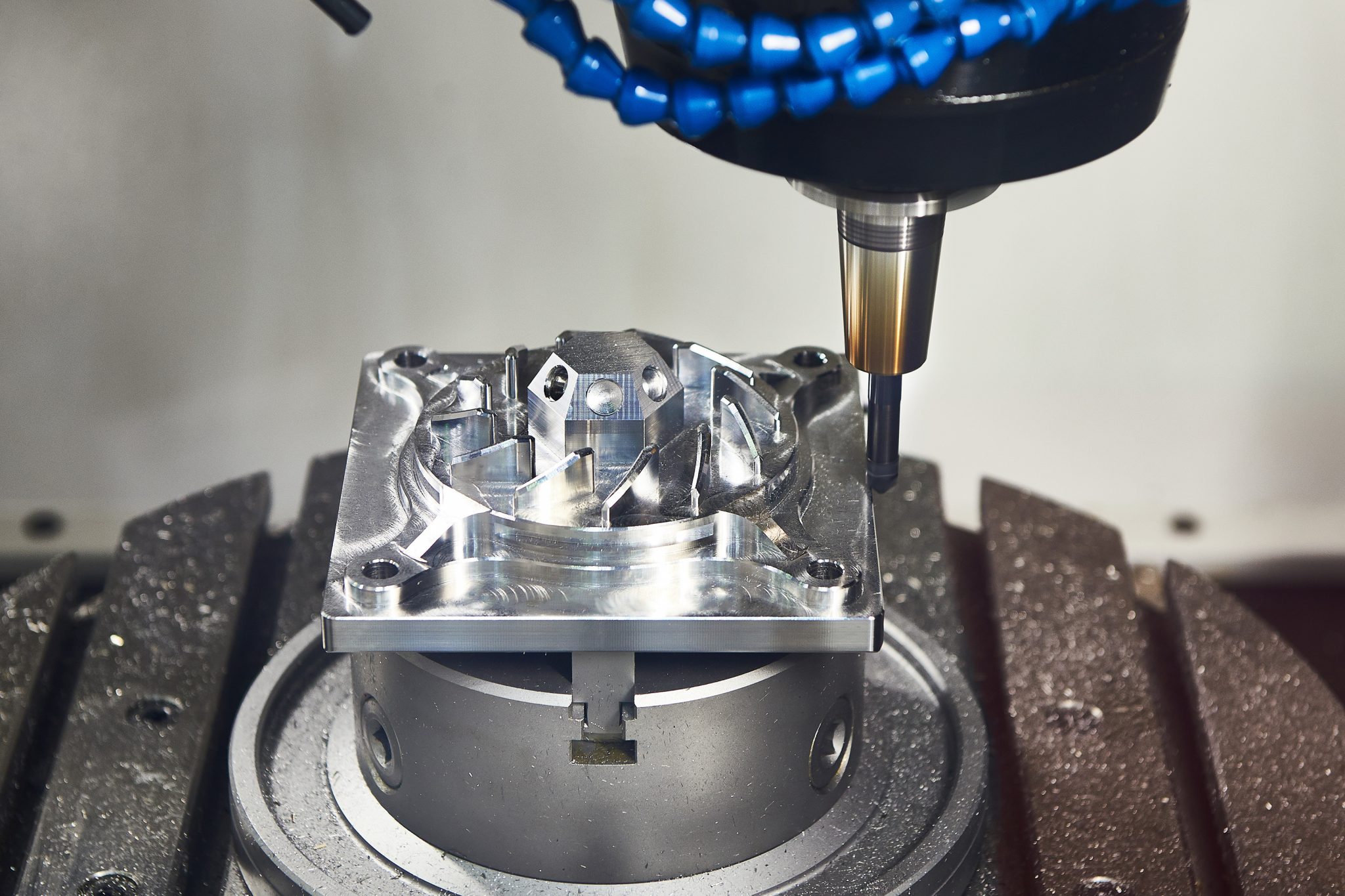

CNC Auto Parts Professional Manufacturer

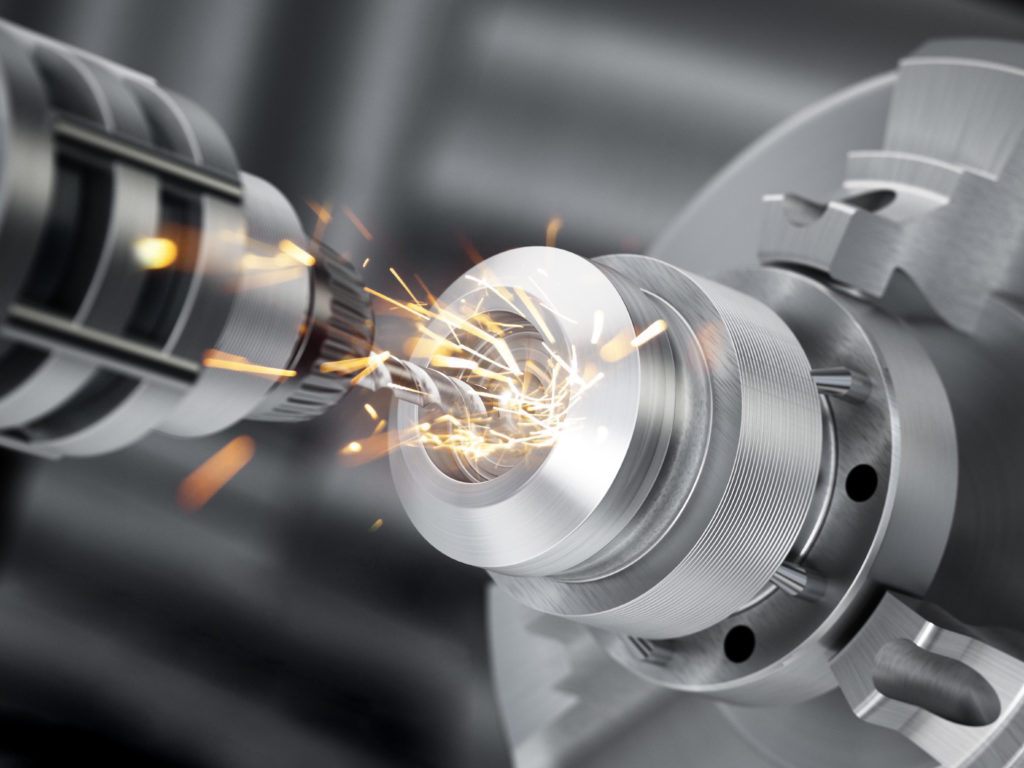

BMT inyanzvi mukugadzira machining, zvisiri-yakajairwa kugadzirwa kwezvikamu, CNC zvimedu zvakawanda kugadzirisa, nhamba yekudzora zvikamu zvemotokari kugadzirisa, batch titanium alloy mune yakanyanya kurongeka zvikamu kugadzira, shaft zvikamu kugadzirisa, semiconductor midziyo yemidziyo kugadzirisa, nezvimwe, ine ruzivo rwakapfuma, yakashongedzerwa. ine CNC machining centre, CNC lathes, waya yekucheka, milling muchina, kugaya muchina, yakavezwa, matatu coordination yekuyeresa chiridzwa, kureba yekuyeresa chiridzwa uye imwe yakakwirira chaiyo kugadzira nekuona michina.

1. Ongorora madhirowa ekugadzirisa uye sarudza maitiro ekugadzirisa

Zvinoenderana nedhirowa yekugadzira yakapihwa nemutengi, vashandi vekuita vanogona kuongorora chimiro, kurongeka kwechimiro, kushata kwepamusoro, workpiece zvinhu, rudzi rusina chinhu uye mamiriro ekupisa ekupisa kwezvikamu, uye wozosarudza chishandiso chemuchina, chishandiso, sarudza iyo yekumisikidza clamping. mudziyo, nzira yekugadzirisa, kutevedzana kwekugadzirisa uye saizi yekucheka dosage. Muchiito chekutarisa machining process, basa rekuraira reCNC muchina mudziyo unofanirwa kutariswa zvizere, kupa kutamba kwakazara kune kugona kwechishandiso chemuchina, kuitira kuti nzira yekugadzira ive inonzwisisika, nguva shoma yebanga uye nguva pfupi yekugadzirisa.

2. Verenga kukosha kwekubatanidza kwenzira yekushandisa zvine musoro

Zvinoenderana nehukuru hwejometri yechikamu chemuchina uye iyo set programming coordination system, nzira yekufamba yepakati pecheki nzira inoverengerwa, uye data rese renzvimbo yekucheka rinowanikwa. General CNC system ine basa rekududzira mutsara uye denderedzwa kududzira, kune zviri nyore planar chimiro zvikamu, senge zvikamu zvemutsara uye arc contour machining, inongoda kuverenga zvinhu zvejometri zvekutanga nenzvimbo yekugumira, iyo denderedzwa arc yedenderedzwa ( kana denderedzwa arc radius), maviri geometrical element mharadzano poindi kana tangent point coordinate values. Kana iyo nc system isina chishandiso chekubhadhara basa, iyo tool center trajectory coordinate value inofanirwa kuverengerwa. Kune zvikamu zvine chimiro chakaoma (senge zvikamu zvinoumbwa neasiri-denderedzwa curve uye pamusoro), zvinodikanwa kushandisa iyo yakatwasuka mutsara segment (kana arc segment) kuenzanisa iyo chaiyo curve kana pamusoro, uye kuverenga kukosha kwekubatanidza kwayo. nodes maererano neinodiwa machining kururama.

3. Nyora CNC machining chirongwa chezvikamu

Zvinoenderana nezvikamu zvenzira yebanga kuverenga iyo nzira yedhata uye magadzirirwo maparamendi akatemerwa uye anobatsira chiito, vashandi vehurongwa vanogona kuenderana nekushandiswa kweiyo NUMERICAL control system inotsanangurwa mumirayiridzo inoshanda uye chimiro chechirongwa, chikamu na. chikamu chekunyora zvikamu zvepurogiramu yekugadzirisa. Kuchenjerera kunofanira kubhadharwa kune: kutanga, kuenzaniswa kwekunyora kwepurogiramu kunofanira kuva nyore kutaura uye kutaurirana; Chechipiri, mukushandiswa kweCNC muchina chishandiso kuita uye mirairo pahwaro hwekujairana kwakazara, kuraira kwekushandiswa kwehunyanzvi, hunyanzvi hwekuronga.