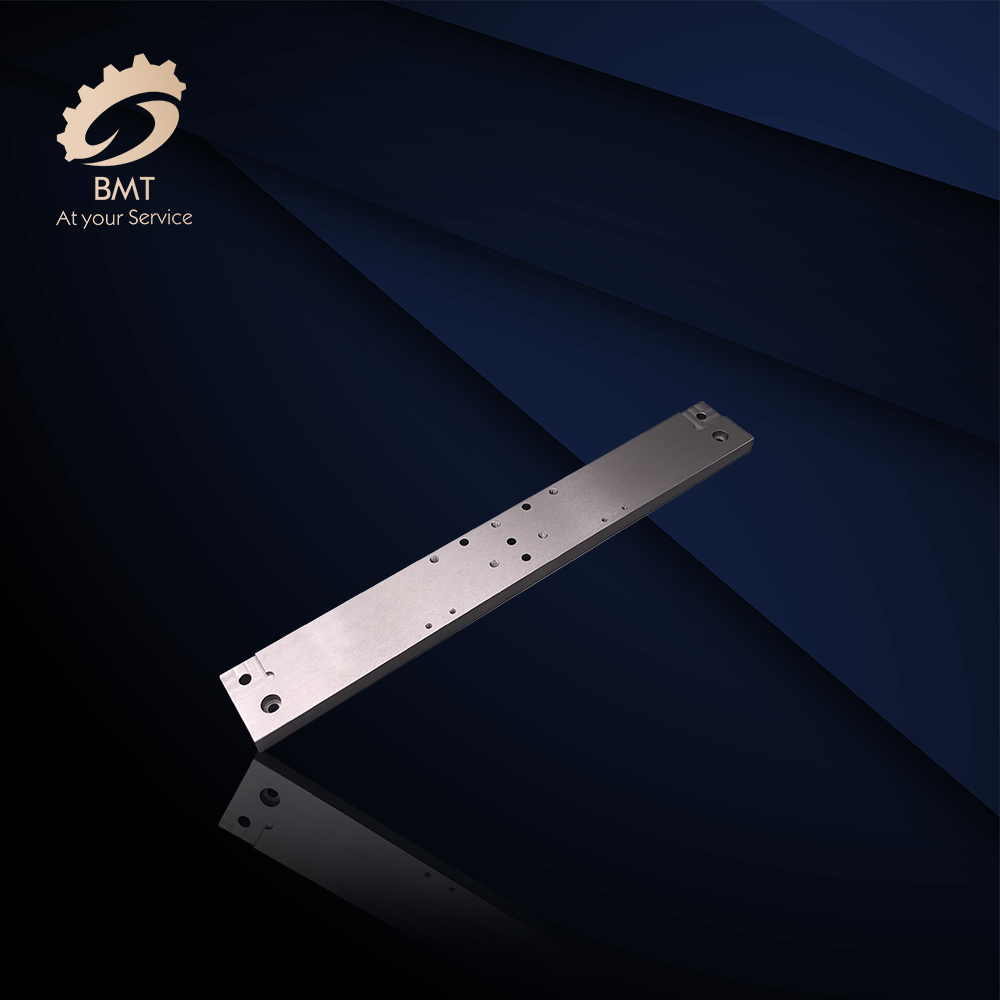

CNC Machining Clamping Unyanzvi

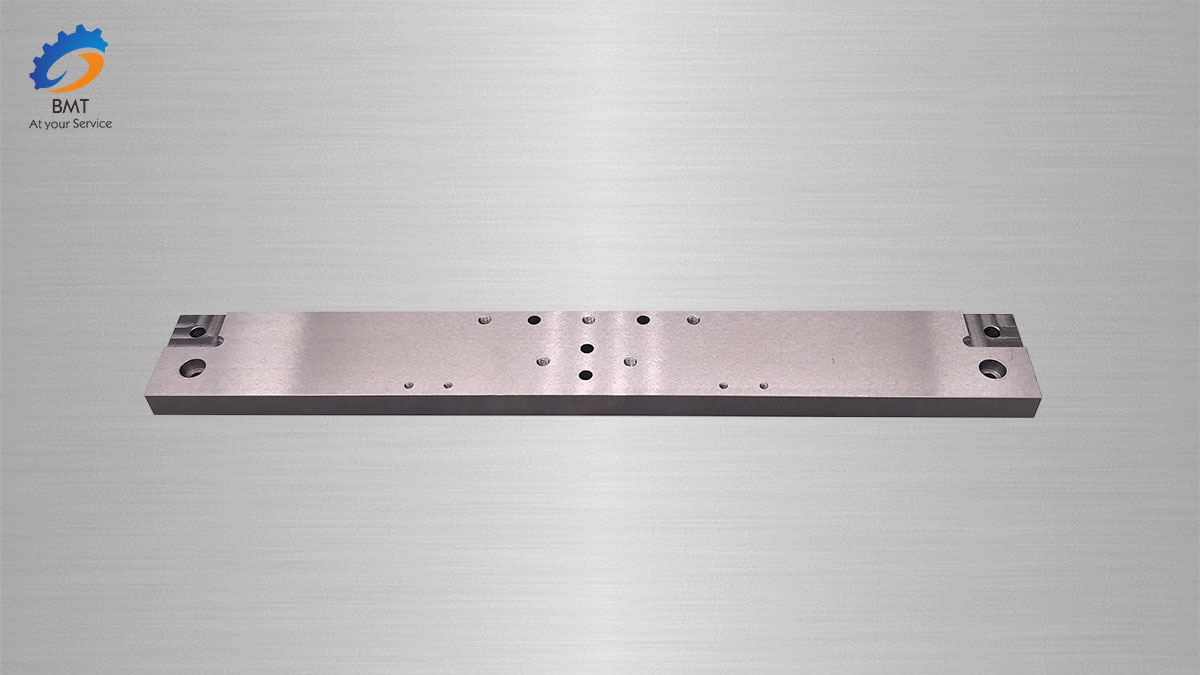

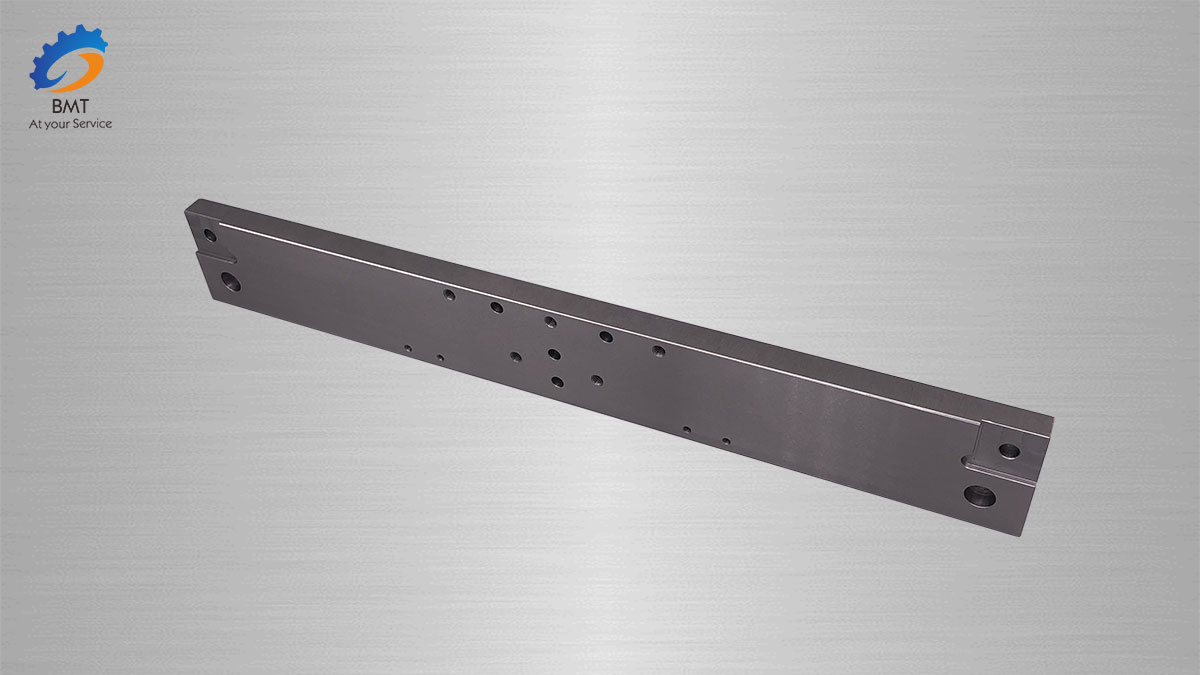

Machining Chikamu Clamping:

Nheyo yakakosha yekupeta chinzvimbo chekuisa

Paunenge uchigadzira zvikamu pane CNC muchina chishandiso, musimboti wekutanga wekuisa uye kumisikidza kusarudza inonzwisisika chinzvimbo datum uye clamping chirongwa. Chenjerera kune zvinotevera pfungwa pakusarudza:

1. Shingairira bhenji yakabatana yekugadzira, maitirwo uye maverengero ehurongwa.

2. Deredzai huwandu hwenguva dzekusunga, uye gadzira nzvimbo dzese kuti dzigadziriswe mushure mekuisa uye kusungirira kamwe chete sezvinobvira.

3. Dzivisa kushandiswa kwemichina-yakagarwa nemanyorero ekugadzirisa zvirongwa zvekupa kutamba kwakazara kune kubudirira kweCNC michina zvishandiso.

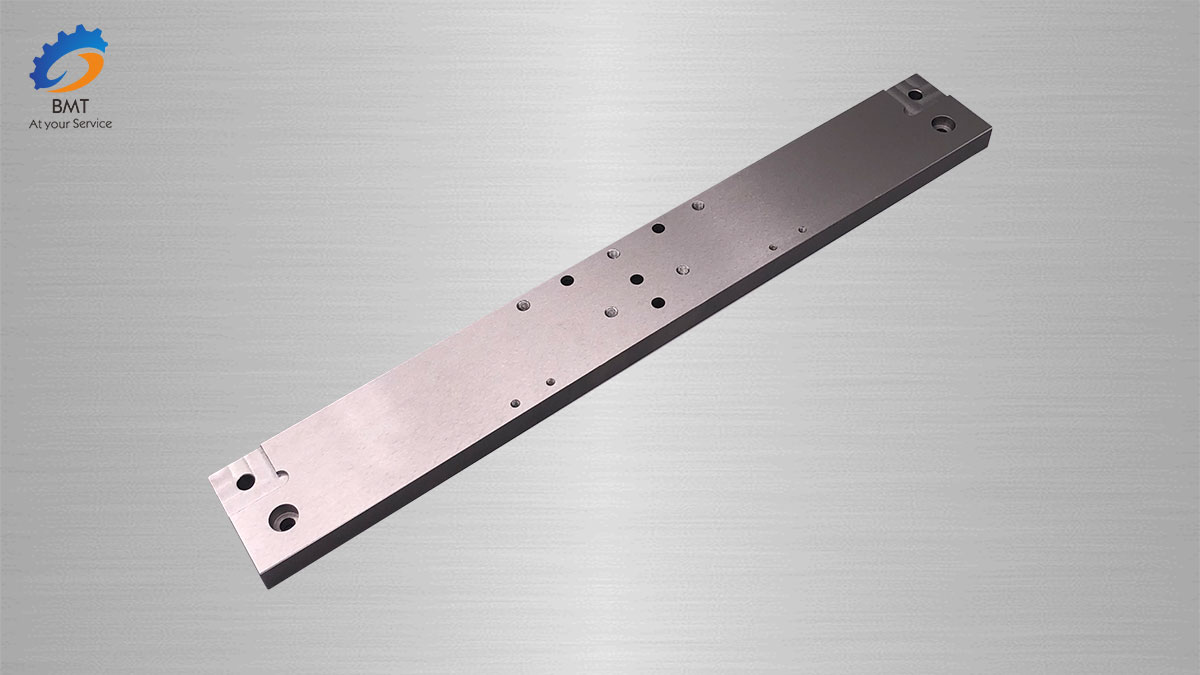

Nheyo dzekutanga dzekupeta nekusarudza zvigadziriso

Hunhu hweCNC machining hunoisa pamberi zviviri zvakakosha zvinodiwa pakugadzirisa: imwe ndeyekuona kuti kurongeka kweiyo dhizaini kwakanyatso kurongeka negwara rekurongeka rechishandiso chemuchina; imwe yacho ndeyekuronga hukama hwehukuru pakati pezvikamu uye muchina wekushandisa coordinate system. Mukuwedzera, zvinotevera zvinofanirwa kucherechedzwa:

1. Kana batch yezvikamu isiri yakakura, modular fixtures, zvinogadziriswa zvigadziriso uye zvimwe zvigadziriso zvakajairika zvinofanirwa kushandiswa zvakanyanya sezvinobvira kupfupisa nguva yekugadzirira kugadzirwa uye kuchengetedza mari yekugadzira.

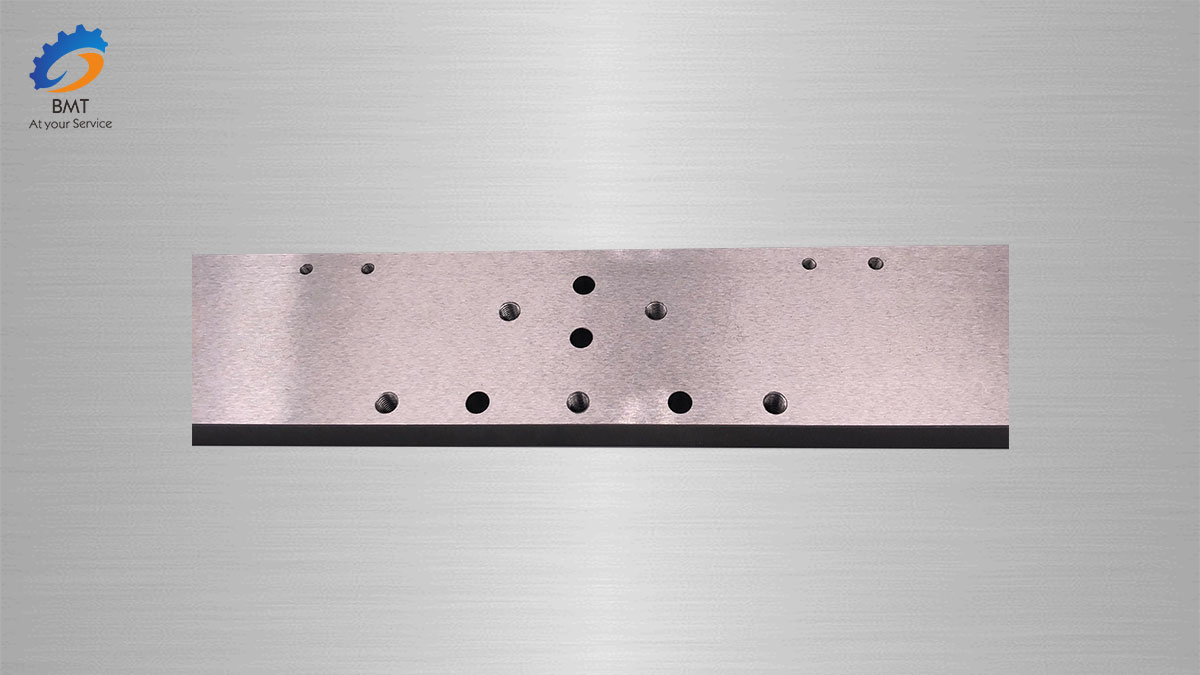

2. Ingofunga nezvekushandiswa kwezvigadziriso zvakakosha panguva yekugadzirwa kwemazhinji, uye edza kuve nechimiro chakareruka.

3. Kurodha uye kurodha kwezvikamu kunofanirwa kunge kuri kukurumidza, kuri nyore uye kwakavimbika kupfupisa muchina wekumisa nguva.

4. Zvikamu zviri pachigadziro hazvifanirwe kutadzisa machining epamusoro pezvikamu nemuchina wemuchina, kureva kuti, chigadziriso chinofanira kuvhurwa, uye kumisikidza kwayo uye kusungirira michina yemagetsi haifanire kukanganisa banga panguva yekugadzirisa (sekudhumhana. , nezvimwewo).

Machining kukanganisa

Nhamba yekudzora machining kukanganisa yekuwedzera inoumbwa nehurongwa hwekukanganisa editing, muchina chishandiso chikanganiso muchina, chinzvimbo chikanganiso chakagadziriswa, chishandiso kuseta chikanganiso chishandiso uye zvimwe zvikanganiso.

1. Kukanganisa kwechirongwa kunoumbwa nekukanganisa kukanganisa δ uye kukanganisa kwekutenderera. Iko kufungidzira kukanganisa δ inogadzirwa mukuita kuswedera kune isiri-yedenderedzwa curve ine mutsara wakatwasuka segment kana denderedzwa arc segment, sezvakaratidzwa muFigure 1.43. Iko kukanganisa kunotenderedza iko kukanganisa kunogadzirwa nekutenderedza kukosha kweiyo coordinate kune integer pulse yakaenzana kukosha panguva yekugadzirisa data. Pulse yakaenzana inoreva kutamiswa kwechikamu chega chega pulse inoenderana neiyo coordination axis. Zvakajairika-chaiyo CNC muchina maturusi kazhinji ane pulse yakaenzana kukosha kwe0.01mm; mamwe chaiwo CNC muchina maturusi ane pulse yakaenzana kukosha kwe0.005mm kana 0.001mm, nezvimwe.

2. Kukanganisa kwechigadzirwa chemuchina kunokonzerwa nekukanganisa kweCNC system uye feed system.

3. Chikanganiso chekumisikidza chinogara chichikonzerwa kana iyo workpiece yakamira pachigadziro uye chigadziriso chakaiswa pamushini wemuchina.

4. Chishandiso chekugadzirisa chikanganiso chekushandisa chinogadzirwa pakusarudza nzvimbo yakaenzana yechishandiso uye workpiece.