Zvishandiso Sarudzo Unyanzvi hweCNC Machining

Sarudza Zvishandiso zveCNC Milling

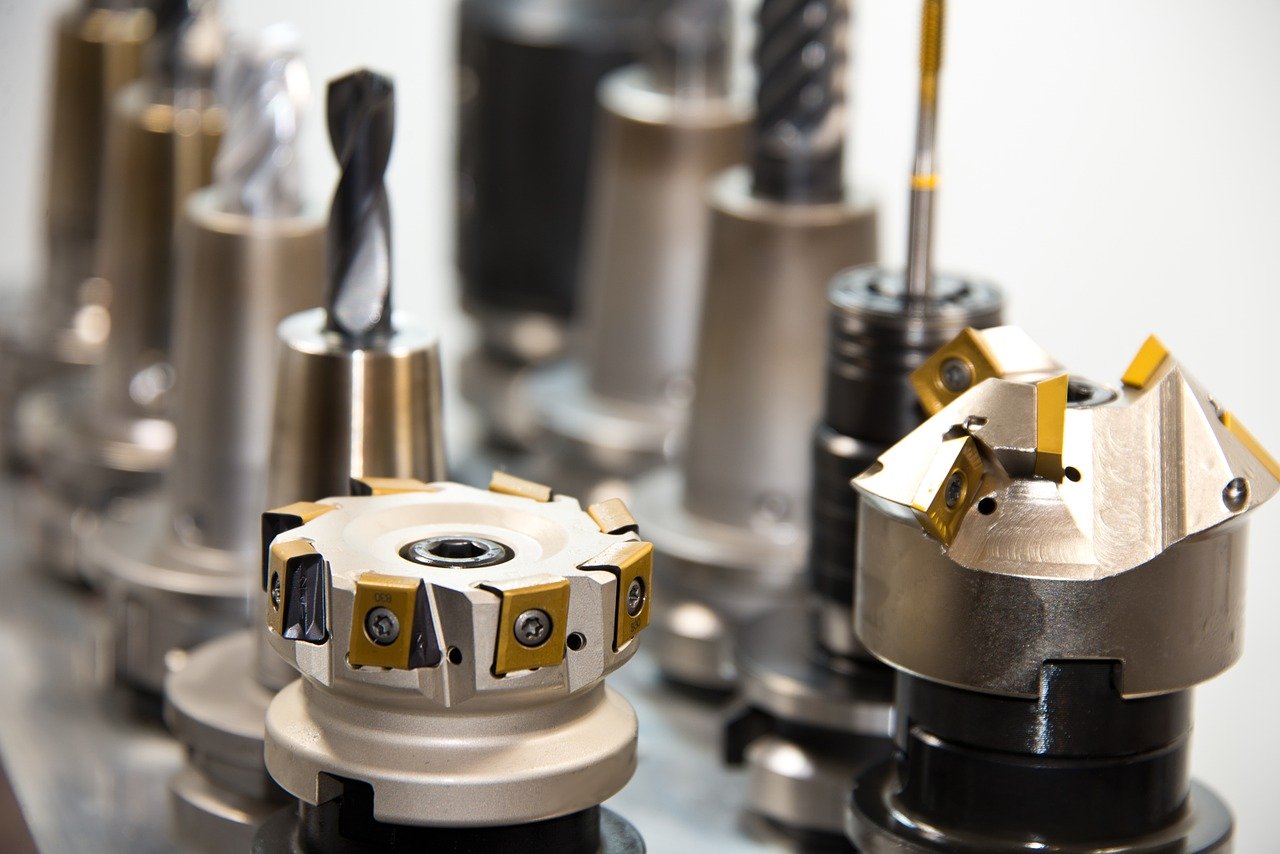

MuCNC machining, zvigayo zvakadzika-pasi zvigayo zvinowanzo shandiswa kugaya mukati nekunze contours yezvikamu zvendege uye ndege yekugaya. Iyo empirical data yeakakodzera ma parameter echishandiso ndeaya anotevera: Chekutanga, radius yeguyo inocheka inofanira kuva idiki pane yakaderera radius ye curvature Rmin yemukati contour pamusoro pechikamu, kazhinji RD = (0.8-0.9) Rmin. . Yechipiri ndiyo kureba kwekugadzirisa kwechikamu H < (1/4-1/6) RD kuona kuti banga rine kusimba kwakakwana. Chechitatu, kana uchikuya pasi pegoro remukati neine flat-bottomed end mill, nekuti mapasi maviri epasi pegirovha anoda kupindirana, uye radius yekumucheto kwezasi kwechishandiso iRe=Rr, ndiko kuti, iyo. dhayamita iri d=2Re=2(Rr), pakurongwa Tora radius yekushandisa seRe=0.95 (Rr).

Pakugadziridzwa kwemamwe matatu-dimensional profiles uye contours ane akasiyana-siyana mabhero angles, spherical milling cutters, ring milling cutter, dhiramu kucheka, tapered milling cutter uye disc milling cutter inowanzoshandiswa. Parizvino, mazhinji eCNC muchina maturusi anoshandisa serialized uye akajairwa maturusi. Kune zviyero zvenyika uye serialized modhi dzevabati vezvishandiso uye misoro yezvishandiso senge indexable muchina-wakasungirirwa ekunze maturusi ekushandura uye maturusi ekutenderedza kumeso. Kune machining nzvimbo uye otomatiki maturusi ekuchinja Maturusi emuchina akaiswa uye zvibatiso zvematurusi akaiswa serial uye akajairwa. Semuenzaniso, iyo yakajairwa kodhi yetapered shank chishandiso system ndeye TSG-JT, uye yakajairwa kodhi yeyakatwasuka shank chishandiso system ndeye DSG-JZ. Uye zvakare, kune yakasarudzwa chishandiso Usati washandisa, zvinodikanwa kunyatso kuyera saizi yechishandiso kuti uwane data chaiyo, uye mutyairi anoisa iyi data muhurongwa hwedata, uye apedze maitiro ekugadzirisa kuburikidza nekufona kwechirongwa, nekudaro kugadzirisa akakodzera workpieces. .

Kupeta Tool Poindi uye Tool Shandura Poindi

Kubva pachinzvimbo chipi icho chishandiso chinotanga kuenda kunzvimbo yakatarwa? Saka pakutanga kwekuitwa kwechirongwa, nzvimbo iyo chishandiso chinotanga kufamba muiyo workpiece coordinate system inofanira kutsanangurwa. Iyi nzvimbo ndiyo yekutanga kwechishandiso chinoenderana neiyo workpiece kana chirongwa chaitwa. Saka inonzi chirongwa chekutangira kana pekutangira. Iyi poindi yekutangira inowanzo temwa neturusi kuseta, saka iyi poindi inodaidzwa zvakare kuti tool setting point. Paunenge uchigadzira chirongwa, chinzvimbo chenzvimbo yekumisikidza chishandiso chinofanira kusarudzwa nemazvo. Iyo musimboti wekumisikidzwa kwechishandiso chekumisikidza ndeyekugonesa kugadzirisa nhamba uye kurerutsa hurongwa.

Zviri nyore kurongedza uye kutarisa panguva yekugadzirisa; kukanganisa kwekugadzirisa kwakakonzerwa idiki. Nzvimbo yekumisikidza chishandiso inogona kusetwa pane yakashongedzwa chikamu, pane gadziriso kana pane muchina chishandiso. Kuti uvandudze kurongeka kwemuchina kwechikamu, nzvimbo yekumisikidza yezvishandiso inofanira kugadzikwa kusvika painobvira pane chikamu chedhizaini referensi kana base process. Mukushanda chaiko kwechishandiso chemuchina, nzvimbo yekumisikidza chishandiso inogona kuiswa panzvimbo yekumisikidza chishandiso nekushandisa manyorerwo ekushandisa, ndiko kuti, kusangana kwe "chishandiso chinzvimbo" uye "chishandiso chekumisikidza nzvimbo". Iyo inodaidzwa kuti "chishandiso nzvimbo nzvimbo" inoreva nzvimbo yekumisikidza datum poindi yechishandiso, uye nzvimbo yenzvimbo yechishandiso chekutendeuka ndicho chekushandisa kana pakati pechishandiso tip arc.

Iyo flat-bottomed end mill ndiyo mharadzano yeaxis yekushandisa uye pasi pechishandiso; bhora-kupera kweguyo ndiro pakati pebhora, uye chibooreso ndiyo poindi. Uchishandisa manyorerwo ezvishandiso zvekumisikidza mashandiro, iko kurongeka kwezvishandiso kwakaderera, uye kushanda kwakaderera. Mamwe mafekitari anoshandisa optical turusi yekuseta magirazi, maturusi ekuseta zviridzwa, otomatiki maturusi ekuseta, nezvimwe kudzikisa turusi yekumisikidza nguva uye kunatsiridza iko kurongeka kwemidziyo. Kana chishandiso chichida kuchinjwa panguva yekugadziriswa, nzvimbo yekushandura chishandiso inofanira kutsanangurwa. Iyo inodaidzwa kuti "tool change point" inoreva nzvimbo yechiturusi kana ichitenderera kushandura chishandiso. Chishandiso chekushandura nzvimbo chinofanira kunge chiri kunze kwechishandiso kana chigadziriso, uye workpiece nezvimwe zvikamu hazvifanirwe kubatwa panguva yekushandurwa kwechishandiso.

Iyo muromo werudzi urwu rwekushandura chishandiso inoumbwa nemitsetse mikuru uye yechipiri yekucheka micheto, senge 900 yemukati nekunze maturusi ekutendeuka, kuruboshwe uye kurudyi kumagumo kumeso ekutenderedza maturusi, grooving (kucheka) maturusi ekushandura, uye akasiyana ekunze uye emukati ekucheka maturusi ane. diki tip chamfers. Gomba rinotenderedza mudziyo. Iyo nzira yekusarudza yejometri paramita yechishandiso chakanongedza chekushandura (kunyanya iyo geometric angle) yakangofanana neyakajairika kutendeuka, asi hunhu hweCNC machining (senge nzira yekugadzira, kupindira kwemuchina, nezvimwewo) inofanirwa kutariswa zvizere. , uye tepi yekushandisa pachayo inofanira kutorwa sesimba.

Sarudza Kucheka Mari

MuNC programming, mugadziri anofanirwa kuona huwandu hwekucheka kwega rega rega onyora muchirongwa nenzira yemirairo. Kucheka maparamendi anosanganisira kumhanya kwespindle, kumashure-kucheka huwandu uye kumhanya kwekudya. Kune nzira dzakasiyana dzekugadzirisa, dzakasiyana siyana dzekucheka paramita dzinoda kusarudzwa. Nheyo yekusarudza yehuwandu hwekucheka ndeyekuona machining echokwadi uye kushata kwepamusoro kwezvikamu, kupa kutamba kwakazara kukucheka kwechishandiso, kuve nechokwadi chekusimba kwechishandiso, uye kupa kutamba kwakazara kuita kwechishandiso chemuchina kuti uwedzere kubereka. uye kuderedza mari.