Zvinhu Zvinokanganisa Kuoma Kwechikamu

- Chikamu Saizi

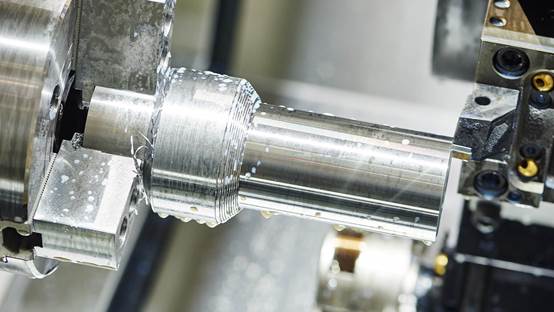

Saizi yega hairatidze kuoma kwechikamu, asi inogona kuve chinhu. Ramba uchifunga, dzimwe nguva zvikamu zvakakura zvakarongwa hazvina kunetsa pane zvidiki, zvakaoma kunzwisisa. Uyewo, funga nezvehukuru hwezvinhu zvega, sezvo izvi zvinokanganisa ukuru hwechigadziro chekucheka chichashandiswa. Chishandiso chakakura, chepamusoro-chekucheka chinogona kubvisa zvinhu nekukurumidza, kuderedza nguva yekugadzira.

- Chikamu chekugadzirisa

Huwandu hwekushanda, kupindira uye cheki inodiwa pachikamu chinozokanganisawo chikamu chakaoma. Zvichienderana nejometri, kupedzisa uye kushivirira nezvimwewo, kurongeka kwekushanda kunogona kuve kwakaoma, kutora nguva uye kutsanangurwa. Semuenzaniso, chikamu chakaoma chingada kuwanda kwekugadzirisa zvakare uye kupindira kwemaoko. Dzimwe nguva, 5 axis kana mill-turn muchina ungave wakanyatsokodzera muchina, semuenzaniso, kana ichidhura-inoshanda kugadzira kana ichida kushoma kwepamusoro mutengo.

- Chikamu kushivirira

Iyo chikamu kushivirira inogona kukanganisa sarudzo yemuchina weCNC unoshandiswa uye unogona kukanganisa mutengo uye nguva yekutungamira. Iko kugoneka kushivirira kunokanganiswawo nezvinhu, machining kumhanya uye tooling. Zvichitaurwa zviri nyore, iyo yakanyanya kushivirira, iyo yakawanda chikamu chako chinodhura. Kushivirira kwakakwirira kunobvumira kunyatsojeka, asi kunogona kusanganisira mamwe maitiro, mashandisirwo, uye maturusi nemichina, nokudaro zvichiwedzera kumutengo.

Mhando dzekupedzisa

- Bead Blasting

Bead Blasting inosanganisira kubviswa kwechero dhipoziti yepasi kana kusakwana pane imwe yunifomu, yakatsetseka kupera. Iwo mabheji akaita sedenderedzwa anovimbisa kupera kwakafanana uye anowanzo shandiswa kupa matt kupera. Finer beads inogonawo kushandiswa kune imwe satin-yakafanana kana yakasviba kupera.

- Anodized apedza

Anodized finishes inopa yakatsanangurwa kupfeka-resistant coating, inowanzowanikwa mune akati wandei mavara. Anodizing inowanzo jeka, uye iyo layer inowanzo tetepa saka iva nechokwadi chekufunga nezve CNC Machine mamaki pamusoro.

- Semuchina

Imwe mhedziso ichasiya kushata kwepamusoro sezvo chidimbu chinogadzirwa. Iyo chaiyo sevhisi roughness inotemerwa uchishandisa Ra kukosha. Kazhinji kushata kwepamusoro kweCNC machined parts is Ra 1.6-3.2µm.

CMM Yekuongorora Mishumo

Chii chinonzi CMM report uye nei ndichichida?

Kuongorora kweCoordinate Measurement Machine (CMM) kunosanganisira kushandisa muchina wekuyeresa wekutarisa hukuru hwechikamu kuti uone kana chikamu chinosangana nezvinodiwa zvekushivirira. A Coordinate Measuring Machine inoshandiswa kuyera kunaka nehunhu hwechinhu.

Kuongororwa kweCMM kunozodiwa kuyera zvimwe zvikamu zvakaoma kuti ive nechokwadi chekuti zvinoenderana nezvakatsanangurwa. Iwo anozowanzo kuverengerwa kune yakanyanyisa-chaiyo zvikamu uko yekupedzisira mhando uye huchokwadi hunodiwa. Panguva ino, kutsetseka kwepamusoro kunopera kunozoongororwawo kuti ive chokwadi kudhirowa uye dhizaini.

A CMM inoshanda nekushandisa probe inoyera mapoinzi pane workpiece. 3 maaxes anoumba muchina wekubatanidza system. Iyo imwe sisitimu ndiyo chikamu chekubatanidza sisitimu, uko 3 maaxes ane hukama / anopindirana kune maficha uye datum yeworkpiece.

Mabhenefiti eCMM Kuongorora

Kuongorora kweCMM kuchaitwa uye pazvinenge zvichidikanwa, uye dzimwe nguva zvinosungirwa. CMM Inspection mishumo inogona kuchengetedza nguva uye kuderedza mutengo wepamusoro nekuona kuti chikamu chakagadzirwa nemazvo dhizaini. Izvi zvinovimbisa kuti hapana chinosiiwa nemukana uye chero kutsauka kubva pakugadzira kana kukanganisa kunowanikwa kusati kwatumirwa.

Zvichienderana neindasitiri, kutsauka kubva pane zvakatemwa kunogona kuva njodzi (Somuenzaniso, indasitiri yezvokurapa, kana indasitiri yezvemuchadenga.) Ichi chekupedzisira chekutarisa chemhando yepamusoro chinogona kupa vimbiso chikamu chisati chasaina uye kuendeswa kune mutengi.