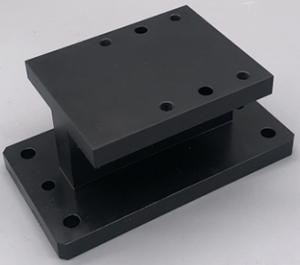

BMT CNC Machining Surface Treatment

Dzimwe nguva, Vatengi vanosarudza simbi pamusoro pekurapa masevhisi mushure mekuita machining paBMT kuvandudza maratidziro ezvikamu, kuwana nzvimbo yakatsetseka, uye kusvika pakuramba kuora, etc. Nemakore anopfuura gumi 'ruzivo neCNC Precision Machining Zvikamu uye akadzidza kubva kune vatengi, vatengi vedu. kazhinji sarudza Oxide Blacking, Polishing, Carburizing, Anodize, Chrome Plating, Zinc Plating, Nickel Plating, Sandblasting, Laser engraving, Heat treatment, Powder Coated, etc. Ndeupi musiyano pakati pemishonga iyi yepamusoro?

| Electroplating | Maitiro ekushandisa magetsi ekudzikisa yakanyungudika simbi cations kuitira kuti vagadzire yakatetepa inobatana simbi coeting pane electrode, kushandura zvimiro zvesimbi pamusoro kana kuvaka ukobvu kune undersized zvikamu. |

|

| Kupukuta | Maitiro ekukwesha pamusoro pezvikamu kana kushandisa kemikari kuita kuti igadzire nzvimbo yakatsetseka uye inopenya, ita kuti nzvimbo yacho iwane kutarisisa kwakakosha kana kuderedza kupararira kutaridzika mune zvimwe zvinhu. |

|

| Painting | Zvinoreva kuchinjika kwepamusoro pekupedzisira maitiro, kupfapfaidza pendi, pigment, kana ruvara kune yakasimba pamusoro seyeruvara inodzivirira layer, uye inogona kuitwa pane simbi kana isiri-simbi CNC mashini ezvikamu zvechero zvimiro, zvinowanzoiswa paaluminium, simbi isina tsvina uye. simbi alloy zvikamu. Chinangwa ndechekuvandudza aesthetic kutaridzika uye kudzivirira ngura kana oxidation. |

|

| Passivation | Iyo yakajairwa kemikari pamusoro pekurapa nzira yesimbi uye simbi isina tsvina, kubvisa ferrous tsvina kana kushandisa mwenje bhachi rezvinhu zvekudzivirira kugadzira goko rekusimudzira kushora kana kuderedza kemikari reactivity. |

|

| Powder coating | Iyo inoshanda uye yekushongedza kupedzisa, iyo inoshandiswa seyakasununguka-inoyerera, yakaoma hupfu, inoshandisa electrostatic uye inoporeswa mukupisa, kugadzira kupera kwakaoma kusimba kupfuura pendi yakajairika. Iwo mashandisirwo makuru anosanganisira midziyo yemumba, aluminium extrusions, chigubhu Hardware, mota, mudhudhudhu, uye zvikamu zvebhasikoro. |

|

| Anodizing | Iyo electrolytic passivation process yekugadzira yakatetepa layer yealuminum oxide kunze kwealuminium CNC yakagadzirwa zvikamu kuti iwedzere kukora kweiyo yakasikwa oxide layer uye kudzivirira simbi, sezvo dhizaini ine yakakwira corrosion uye abrasion kuramba kupfuura aruminiyamu. |

|

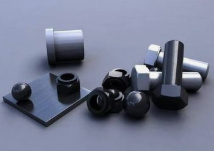

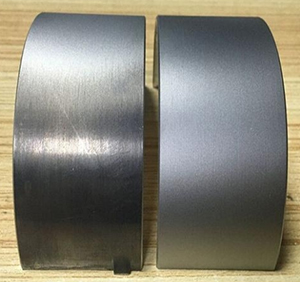

| Black oxide | Mushonga wemakemikari wekugadzira dema rekushandura coating pasimbi isina tsvina, mhangura nemhangura yakavakirwa alloys, zingi, simbi dzehupfu, sirivheri solder, uye ferrous zvinhu, kunatsiridza kusaora uye kuderedza kupenya kwechiedza. |  |

| Abrasive blasting/ Sandblasting | Maitiro kana kushanda kwekufambisira rwizi rwezvinhu zvinoputika zvinoumbwa neakakwira-velocity jecha-saizi zvimedu zvichipesana nesimbi pasi pekumanikidzwa kwakanyanya nemidziyo yekuputika senge air pressure system, kubvisa zvinosvibisa pamusoro, simbi dzakachena kana kuwedzera maumbirwo, wobva wachinja kutsvedzerera kana kushata kwepamusoro. |

|

| Phosphating | Mushonga wemakemikari wekurapa pamusoro pesimbi, uko zvisinganyanyi kunyungudika simbi-phosphate layer inoumbwa pahwaro zvinhu. Iwo maturu akagadzirwa ane porous, anonwisa uye akakodzera seyeshanduko dhizaini kune inotevera hupfu yekuputira pasina kumwe kurapwa. |  |

BMT inopawo kukuya, maindasitiri etching, uye imwe tsika simbi yekupedzisa sevhisi yekupa yakanakisa mhedzisiro yechikamu chako. Ingotiudza zvaunoda uye isu tichatarisira zvimwe!

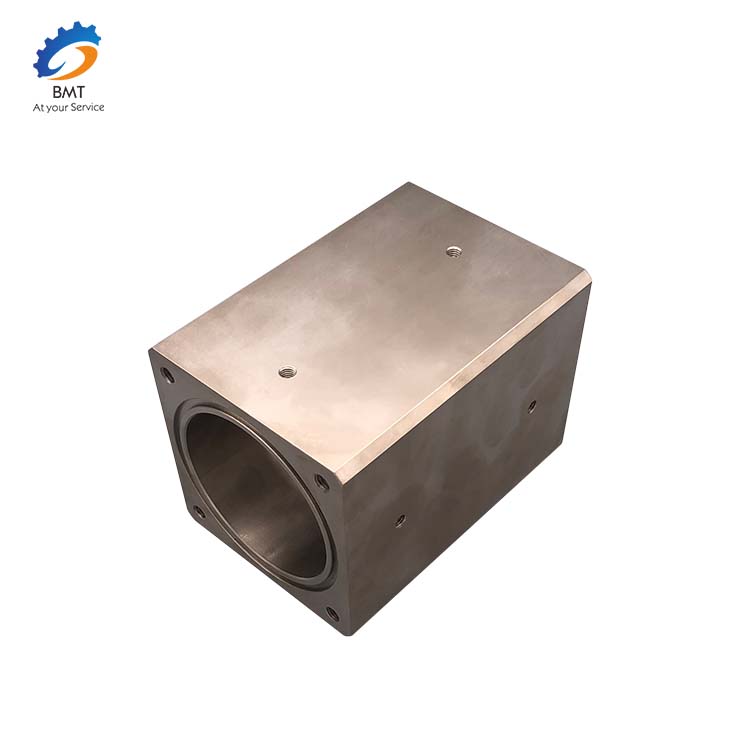

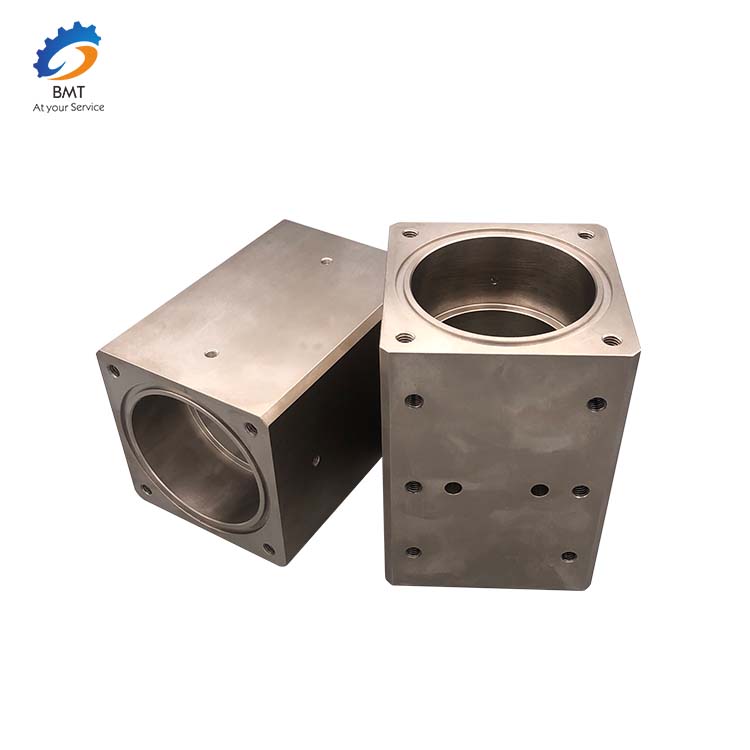

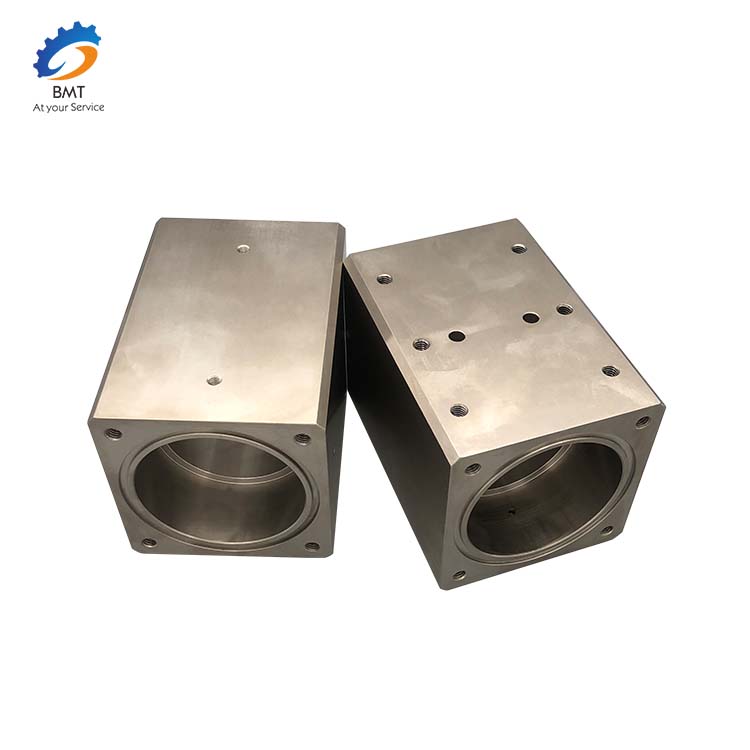

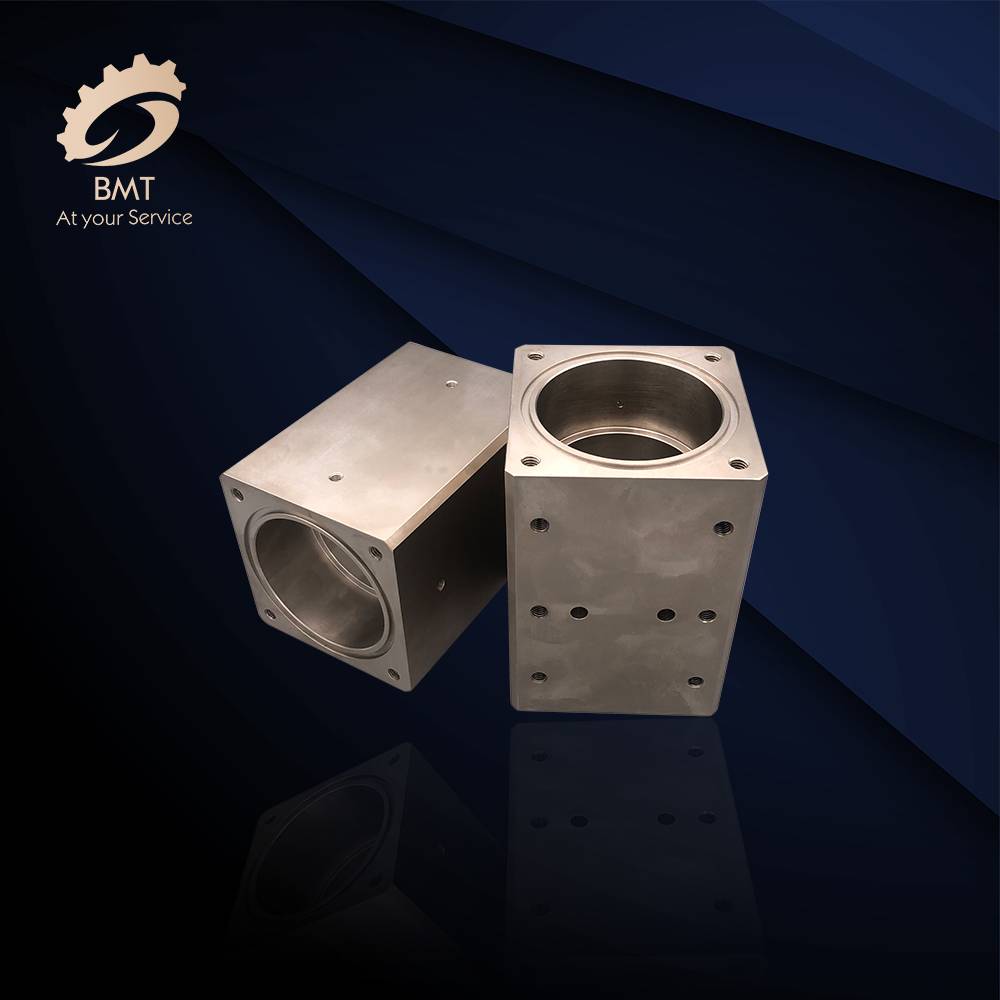

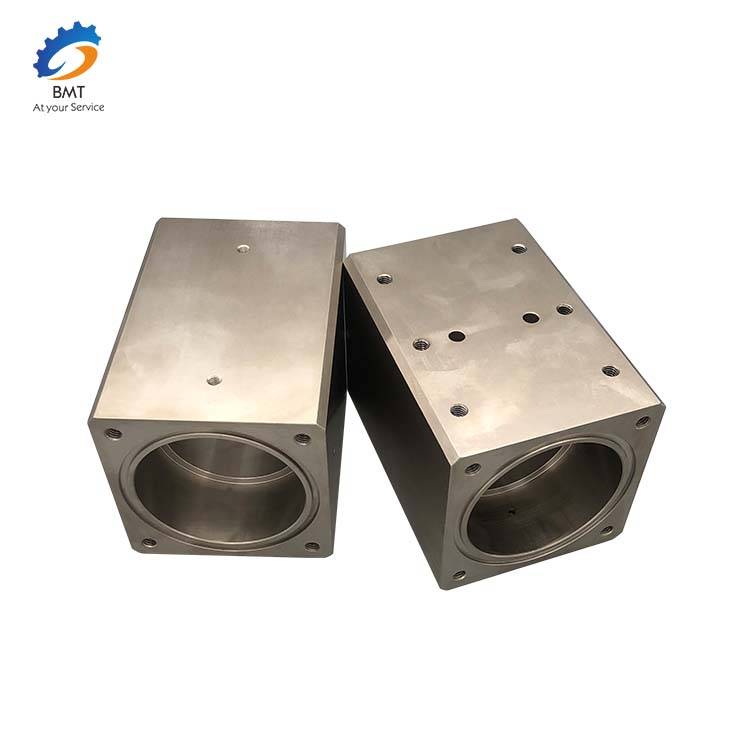

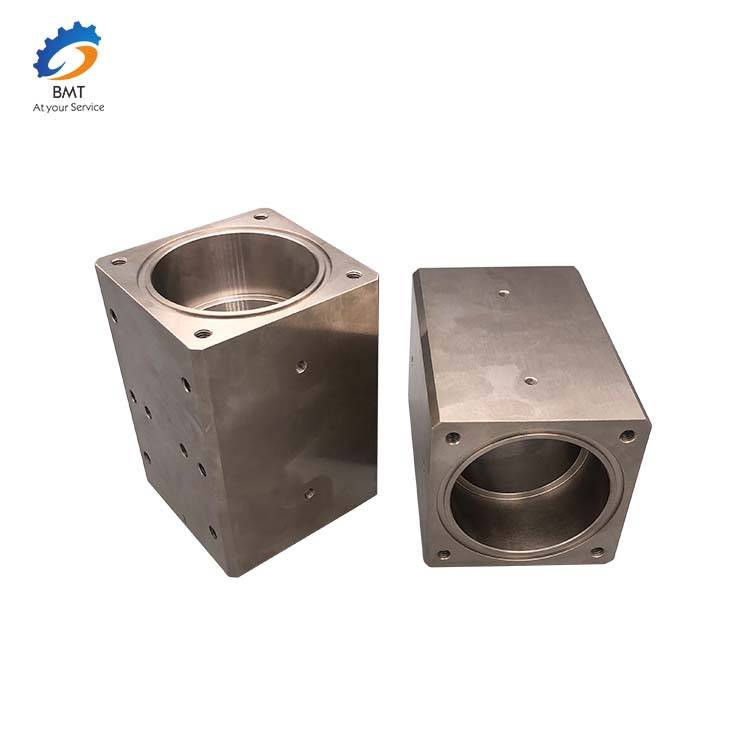

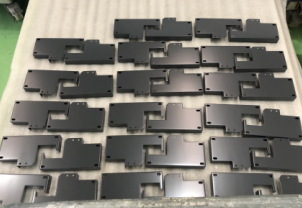

Product Description