Zvakaita seiCNC Machiningkuenda munguva pfupi yapfuura?

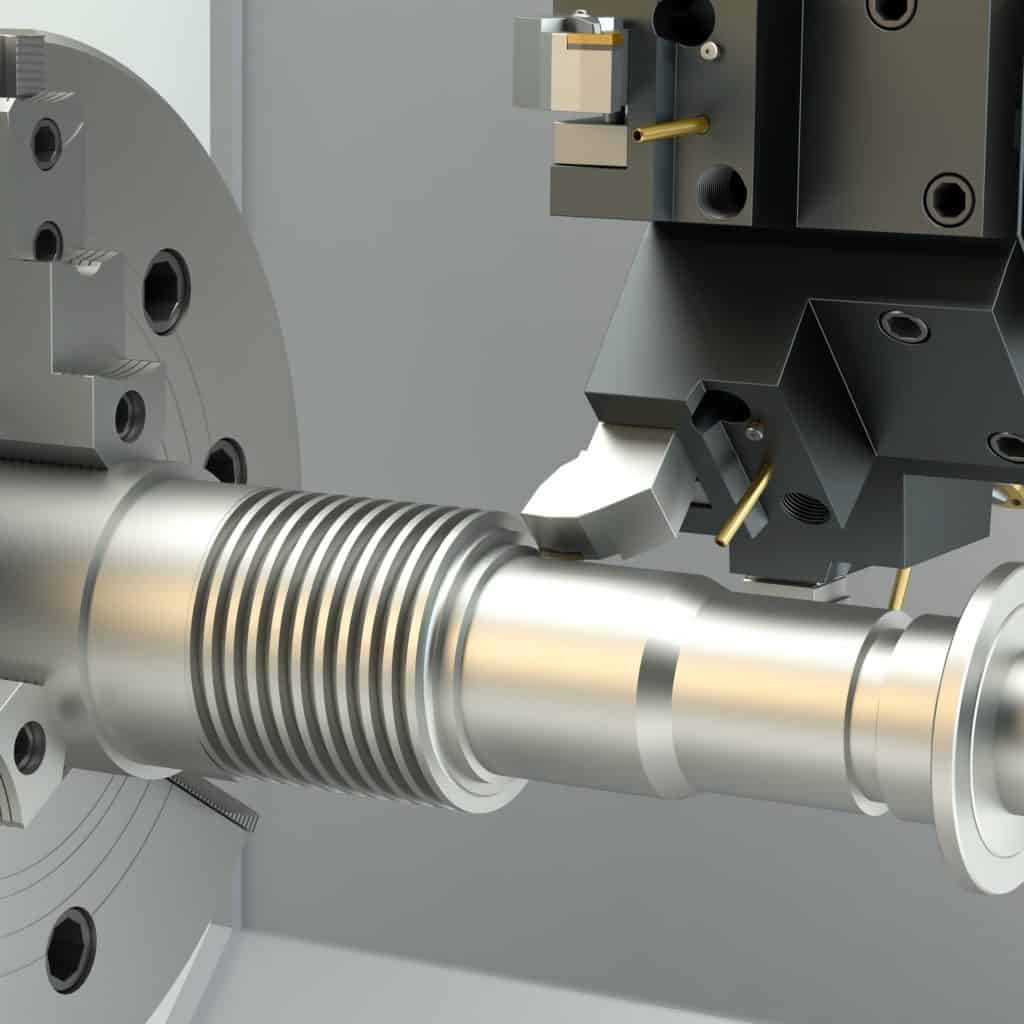

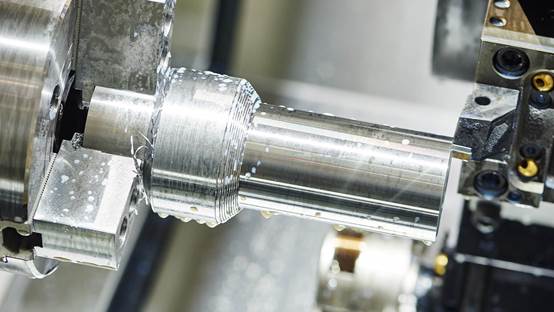

Parizvino, mukugadziriswa kwezvikamu zvemechanicha, izvo zvekushandisa zvakakodzerwa kugadzira simbi isina tsvina isimbi yakakwirira-yekumhanya uye simende carbide. High-speed steel milling cutters zviri nyore kugadzira, zvisingadhure, zvakapinza, uye zvine kusimba kwakanaka, asi zvine kusasimba kwekupfeka. Iyo nzira yekugadzira simende ye carbide milling cutters yakaoma uye inodhura, uye ine yakanaka kupfeka kuramba pasi peyakanyanya-kumhanya kucheka mamiriro, ayo anobatsira kugadzikana kweiyo dimensional kurongeka kweiyo chaiyo mechanic zvikamu kugadzirisa.

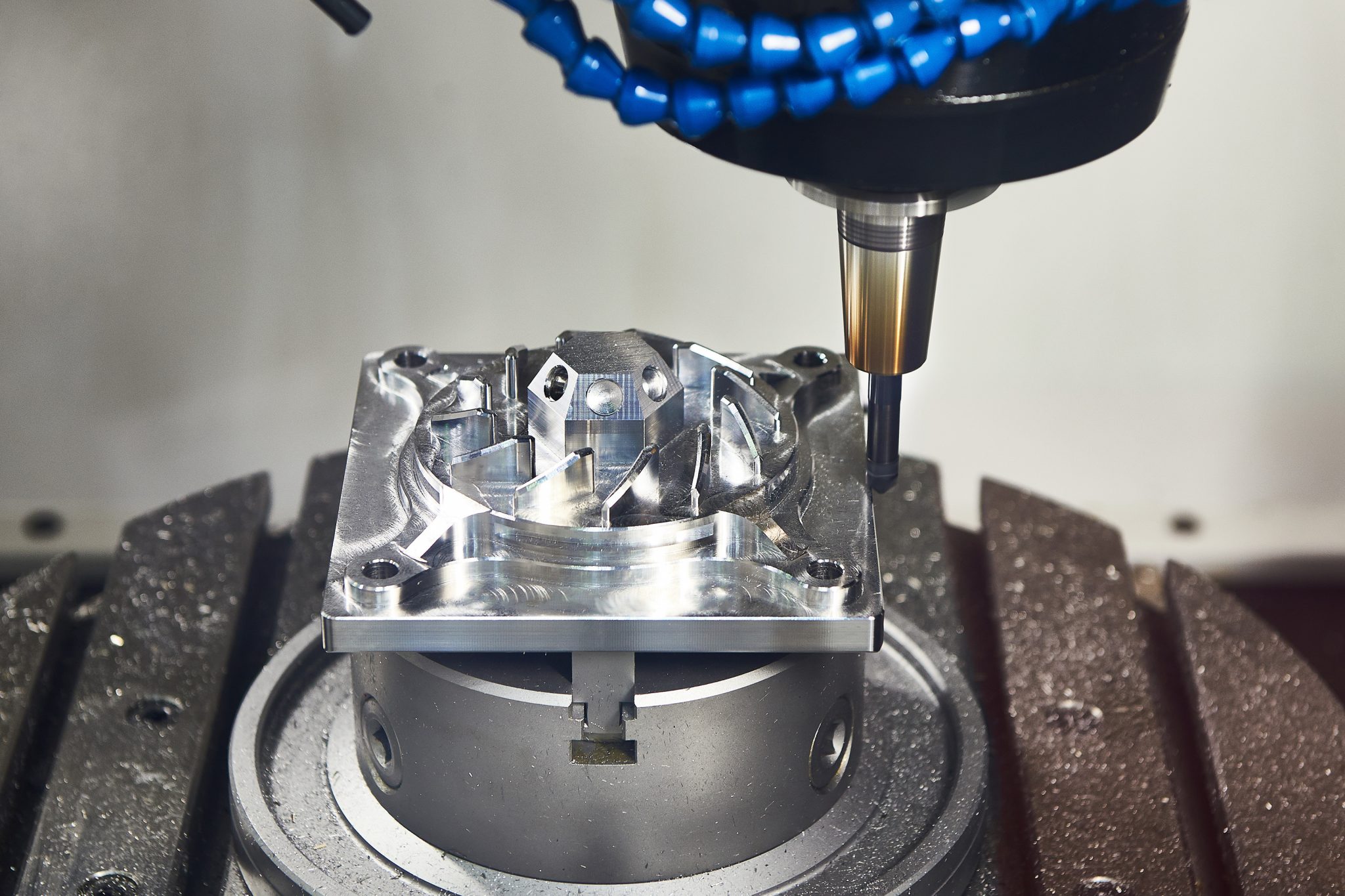

Tichitarisa zvizere maitiro eCNC machining uye hupfumi hwekugadzira, zvinotevera zvinogona kugamuchirwa: shandisa yakakwirira-yepamusoro-yekumhanya simbi yekugaya cutters yekupedzisa, nekuti mablades emhando yepamusoro-yepamusoro-inomhanya simbi yekugaya cutters inopinza. Iyo yakaoma machining inoda kudzika kwakadzika kwechishandiso kuseta, nyore maturusi kuseta, nguva pfupi yekubatsira, uye yakaderera mutengo wekugadzira. Kana wapedza, shandisa yakakwira-yakanyatso coated carbide end mills, inogona kucheka nekumhanya uye kuchengetedza inoenderera uye yakagadzikana machining ikoprecision mechanical parts. Mumamiriro ezvinhu akajairwa, kupera kwemakumi kana mazana ezvigadzirwa zvinogona kupedzwa.

Kusarudzwa kwechishandiso geometrical paramita: Kusarudza chishandiso kubva pane iripo helix inoda kufunga nezve geometrical paramita senge nhamba yemeno, rake angle uye blade helix angle. Mukupedzisa, simbi isina tsvina machipisi haisi nyore kupeta. Chishandiso chine nhamba shoma yemazino uye hombe chip homwe inofanira kusarudzwa kuita chip kubviswa kupfava uye kunobatsira pakugadziriswa kwesimbi isina simbi precision mechanical zvikamu.

Nekudaro, kana iyo angle angle yakawandisa, inonetesa simba uye kupfeka kushomeka kwekucheka kumucheto kwechishandiso. Kazhinji, guyo rekupedzisira rine yakajairika rake angle ye10-20 madhigirii rinofanira kusarudzwa. Iyo helix angle ine hukama neiyo chaiyo rake angle yechishandiso. Kana uchigadzira simbi isina tsvina, kushandiswa kweiyo hombe helix angle milling cutter inogona kuita kuti simba rekucheka rive diki muprecision machiningprocess uye machining akagadzikana.

Hunhu hwepamusoro hwechishandiso chakakwirira, uye helix angle inowanzoita 35 ° -45 °. Nekuda kwekusashanda zvakanaka kwekucheka, tembiricha yekucheka yakakwirira uye hupenyu hupfupi hwematurusi emidziyo yesimbi. Naizvozvo, kushandiswa kwekucheka kwekugaya simbi isina tsvina kunofanirwa kuve kwakadzikira pane iyo yakajairwa kabhoni simbi.

Kutonhodza kwakaringana uye mafuta ekuzora anogona kuwedzera zvakanyanya hupenyu hwechishandiso uye kuvandudza kunaka kwepamusoro kwezvikamu zvemakanika mushure mekugadzirisa. Mukugadzira chaiko, yakakosha simbi yekucheka oiri inogona kusarudzwa seinotonhodza, uye basa rekubuda kwemvura renzvimbo yekudzvanya yepakati yemuchina wemuchina spindle inogona kusarudzwa. Mafuta ekucheka anopfapfaidzwa kunzvimbo yekucheka pakumanikidzwa kukuru kwekumanikidzika kutonhora uye mafuta kuti awane kutonhora kwakanaka uye lubrication effect.

As makambani ekugadzira machinaramba uchivandudza kurongeka kwezvikamu uye zvikamu, CNC machining inoita basa rinowedzera kukosha muhurongwa hwese hwekugadzira, uye mamwe maturusi emuchina weCNC anotengwa, izvo zvinotungamirawo kune akatevedzana matambudziko anoda kugadziriswa nekukurumidza. . Muchiito chekugadzirisa zvikamu zvemakina, maturusi ekucheka, sechishandiso chakakosha chekubatsira kutora chikamu mumabasa ekugadzira, inoita basa rakakura mukugadzirwa kweCNC muchina maturusi uye nekurongeka uye kurongeka kwekunyatso gadzira uye kugadzira zvikamu, kunyanya mukuwedzera. nhamba ye CNC muchina maturusi. Kuti ugadzirise zvipingamupinyi zvinounzwa nedecentralized manejimendi, kuvandudza kushanda kweiyo chaiyo mekiniki zvikamu kugadzirisa, uye kuderedza mutengo wekushandisa, huwandu hwezvishandiso hwakakura. Zvadaro, maturusi anofanira kutungamirirwa nenzira yepakati.

Nguva yekutumira: Mar-15-2021