Pulse uye Inoenderera Wave Modes

Chikamu chakakosha che optical micromachining ndiko kuendesa kupisa kunzvimbo ye substrate iri padyo neiyo micro-machine zvinhu. Lasers inogona kushanda mu pulsed mode kana inoenderera mberi wave mode. Mukuenderera mberi wave mode, iyo laser inobuda inogara ichienderera nekufamba kwenguva.

Mune pulsed mode, iyo laser inobuda inonamirwa mune madiki pulses. Pulsed mode laser zvishandiso zvinopa pulses uye diki pulse durations ine simba rakakwana re micromachining yechinhu chakapihwa. Diki pulse duration inoderedza kupisa kuyerera kune zvakatenderedza zvinhu. Laser pulses inogona kusiyana pakureba kubva milliseconds kusvika femtoseconds.

Iyo simba repamusoro rine hukama nehurefu hweiyo laser pulse, saka pulsed lasers inogona kuwana yakakwira yepamusoro pane mafungu anoenderera.

Kugadziriswa kweLaser kunonyanya kusanganisira kusangana kunotungamira mukubviswa kweiyo substrate zvinhu. Iko kuchinjisa simba kunoitika kunoenderana nezvinhu uye laser zvivakwa. Laser maitiro ayo ari kupesvedzera zvinhu anosanganisira peak simba, pulse wide, uye emission wavelength. Kufunga kwezvinhu ndezvekuti inogona kutora laser simba kuburikidza nekupisa uye / kana photochemical maitiro.

Nei hupamhi hwepuruzi hwakakosha?

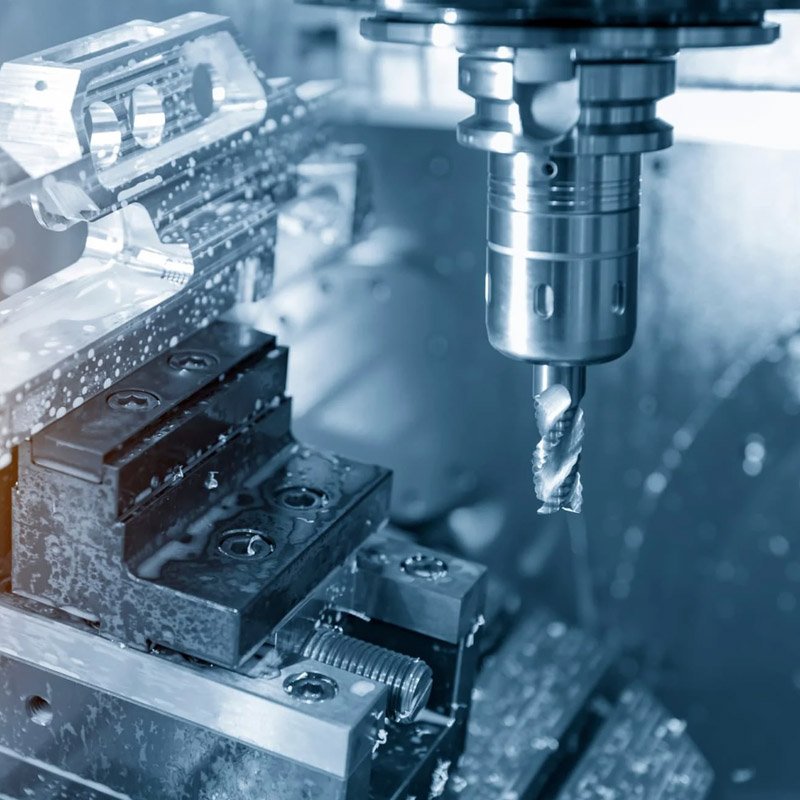

Laser kucheka kwakachena uye kwakaringana. Iko kudikanwa kwekugadzira zvidiki, nekukurumidza, kureruka uye kuderera mutengo zvishandiso zvinoda lasers kusangana nedambudziko. Pulsed lasers inoshandiswa kunyatsoita micromachining yezvinhu zvakasiyana. Iko kugona kugadzira akasiyana pulse wides ndiyo kiyi yekurongeka, throughput, kunaka uye mutengo-kubudirira.

Nanosecond lasers anoshandisa avhareji simba nereti yepamusoro yekubvisa zvinhu uye nekudaro kukwirira kwepamusoro kupfuura picosecond uye femtosecond lasers.

Picosecond uye femtosecond lasers inonyungudutsa zvinhu kuti zviibvise kuburikidza nemaitiro ekuputira uye kunyungudutsa zvinhu kuti zviibvise. Uku kunyunguduka kunogona kukanganisa kurongeka uye kunaka kwekugadzira, sezvo iyo yakabviswa inogona kunamatira kumicheto uye kusimbisazve.

Kufambira mberi mune pulsed laser tekinoroji kwaita kuti zvikwanise kushandisa micromachining pamidziyo midiki, senge michina yekurapa, ine kushomeka kukuvadzwa kwezvinhu zvakatenderedza. Nekukurumidza kufambira mberi kwesainzi mumunda we lasers, laser micromachining hunyanzvi hwakakosha.

Kugadzirwa kwemuchina kunoreva maitiro ese ekugadzira chigadzirwa kubva kune yakabikwa (kana semi-yakapera zvigadzirwa). Pakugadzirwa kwemichina, kunosanganisira kutakura uye kuchengetwa kwezvinhu zvakasvibirira, kugadzirira kugadzirwa, kugadzirwa kusina chinhu, kugadzirwa kwezvikamu uye kupisa kupisa, kusangana kwechigadzirwa, uye kugadzirisa, kupenda uye kurongedza, nezvimwewo. Mabhizinesi emazuva ano anoshandisa misimboti uye nzira dzeinjiniya masisitimu kuronga uye kutungamira kugadzirwa, uye anoona maitiro ekugadzira sehurongwa hwekugadzira ine yekupinza uye inobuda.

Nguva yekutumira: Oct-13-2022