Titanium Seamless Pipes uye Tubes

Gr1, Gr 2, Gr 3 ese maindasitiri akachena titanium.Ivo vane yakakwira mechanic zvivakwa, yakanakisa stamping kuita, uye inogona kuvezwa mumhando dzakasiyana siyana.Simba rekubatanidzwa kwe welded rinogona kusvika 90% yesimba resimbi yepasi, uye kucheka kushanda kwakanaka.Titanium chubhu ine yakakwira corrosion kuramba kune chloride, sulfide uye ammonia.Kudzivirirwa kwekuora kwetitanium mumvura yegungwa kwakakwira kupfuura iyo yealuminium alloys, simbi isina tsvina, uye nickel-based alloys.Titanium zvakare inoshingirira kukanganiswa kwemvura.

Titanium alloy inonyanya kushandiswa kugadzirwa kwendege injini compressor zvikamu, zvichiteverwa nezvikamu zvemaroketi, makombi uye ndege dzinomhanya.Pakati pemakore ekuma1960, titanium nemaaroyi ayo akashandiswa muindasitiri yakajairika kugadzira maelectrode muindasitiri yemagetsi emagetsi, macondenser muzviteshi zvemagetsi, maheater ekunatsa peturu uye kubvisa munyu mumvura yegungwa, uye midziyo yekudzora kusvibiswa kwezvakatipoteredza.Titanium nema alloys ayo ave rudzi rwezvimiro zvinodzivirira corrosion.Uye zvakare, inoshandiswawo mukugadzira hydrogen kuchengetedza zvinhu uye chimiro chendangariro alloys.

Kuenzaniswa nezvimwe zvinhu zvesimbi, titanium alloy ine zvinotevera zvakanakira:

- Yakakwirira chaiyo simba (tensile simba / density), tensile simba rinogona kusvika 100 ~ 140kgf/mm2, uye density inongova 60% yesimbi.

- Tembiricha yepakati ine simba rakanaka, tembiricha yekushandisa inosvika mazana akati wandei madhigirii akakwira kupfuura ayo aruminiyamu alloy, inogona kuramba ichichengetedza simba rinodiwa pane yepakati tembiricha, uye inogona kushanda kwenguva yakareba pane tembiricha ye450 ~ 500 ℃.

- Good corrosion resistance.Imwe yunifomu uye dense oxide firimu inokurumidza kuumbwa pamusoro petitanium mumhepo, iyo inokwanisa kurwisa ngura nema media akasiyana.Kazhinji, titanium ine yakanaka corrosion kuramba mune oxidizing uye kwayakarerekera midhiya, uye ine zvirinani kusakara mukuora mumvura yegungwa, wet chlorine uye chloride mhinduro.Asi mukuderedza midhiya, senge hydrochloric acid uye zvimwe zvigadziriso, iyo corrosion resistance yetitanium haina kunaka.

- Titanium alloys ine yakanaka yakaderera tembiricha kuita uye yakaderera zvakanyanya interstitial zvinhu, senge Gr7, inogona kuchengetedza imwe dhigirii repurasitiki pa -253 ℃.

- Iyo modulus ye elasticity yakaderera, iyo yekupisa conductivity idiki, uye haina-ferromagnetic.

BMT inyanzvi mukutumira kunze isina musono titanium mapaipi nemachubhu, uye kuve nekugadzirwa kwepagore kwe5,000 matani.BMT mapaipi asina musono uye machubhu anoratidza yakakwira chaiyo simba, corrosion resistance, yakanaka cryogenic pfuma, yakaderera elasticity modulus, yakaderera thermal conductivity uye hapana ferromagnetism.

BMT huwandu hwesina musono titanium pombi uye chubhu inotengesa zvakafara kutenderera pasirese.Kutariswa kwakarurama kunoitwa maererano nemhando yemhando, kusanganisira chemial chikamu chekuongorora, kuongororwa kwemhepo yemhepo, nondestructive kuyedza, eddy ikozvino kuyedza uye ultrasonic bvunzo.Isu tinewo mechaniki tesing, inovhara tensile bvunzo, flaring bvunzo, flattening bvunzo, ferroxyl bvunzo, RT, X-Ray bvunzo, nezvimwe.

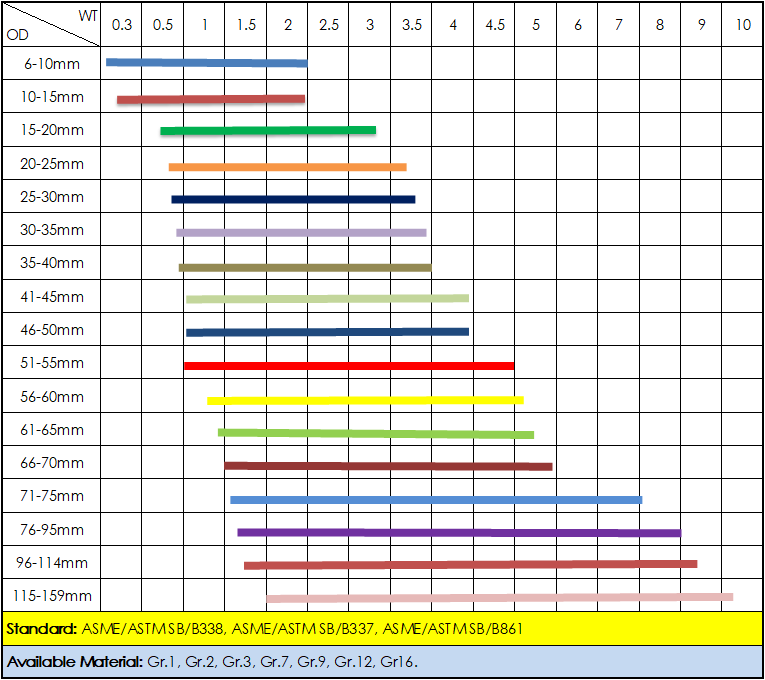

Titanium Seamless Pipes uye Tubes Size Range:

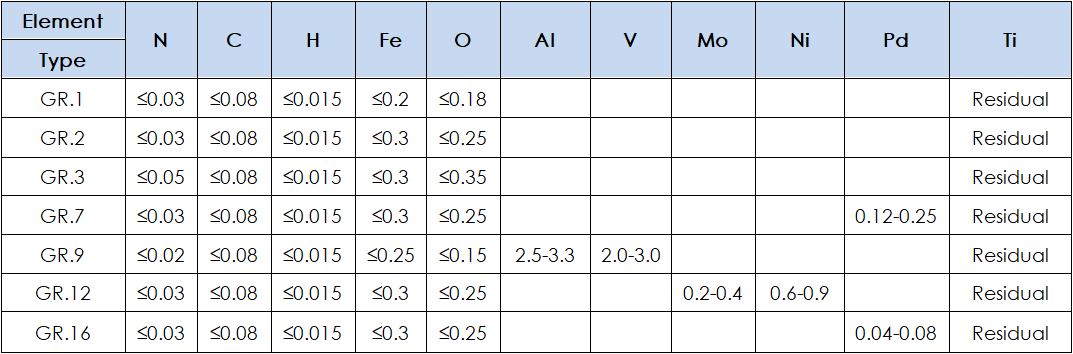

Inowanikwa Material Chemical Composition:

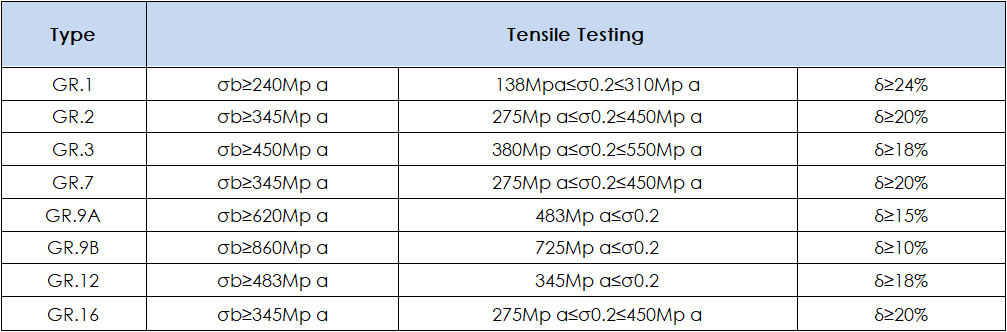

Inowanikwa Material Mechanical Property:

Inspection test:

- Chemical Composition Analysis

- Mechanical Property Test

- Tensile Testing

- Flaring Test

- Flattening Test

- Bending Test

- Hydro-Static Test

- Pneumatic Test (Air pressure test pasi pemvura)

- NDT Test

- Eddy-Yazvino Muedzo

- Ultrasonic Test

- Muedzo weLDP

- Ferroxyl Test

Kugadzirwa (Max uye Min huwandu hweOdha):Unlimited, maererano nehurongwa.

Nguva Yekutungamira:Nguva yekufambisa yakawanda mazuva makumi matatu.Nekudaro, zvinoenderana nehuwandu hweiyo odha zvinoenderana.

Zvekufambisa:Iyo yakajairika nzira yekufambisa ndeyeGungwa, neMhepo, ne Express, neChitima, iyo ichasarudzwa nevatengi.

Packing:

- Pombi inopera kuchengetedzwa nepurasitiki kana kadhibhodhi zvivharo.

- Zvese zvigadziriso zvinofanirwa kurongedzerwa kudzivirira magumo uye kutarisana.

- Zvimwe zvinhu zvese zvichange zvakazara nefuro pads uye zvine chekuita nepurasitiki kurongedza uye plywood makesi.

- Chero huni hunoshandiswa kurongedza hunofanirwa kuve hwakakodzera kudzivirira kusvibiswa nekusangana nemidziyo yekubata.