Titanium Alloy Welding

Icho chikamu chimwechete che alloy chinoumbwa ne β-chikamu chakasimba mhinduro. Pasina kurapwa kwekupisa, ine simba rakakwirira. Mushure mekudzima uye kuchembera, iyo alloy inofambiswa.Imwe danho rekusimbisa, iyo tembiricha yekamuri simba inogona kusvika 1372 ~ 1666 MPa; Asi kugadzikana kwekupisa kwakashata, hakufanirwe kushandiswa pakupisa kwakanyanya.

Iyo biphasic alloy, ine yakanaka yakazara zvivakwa, yakanaka chimiro kugadzikana, yakanaka kuoma, plastiki uye yakakwirira tembiricha deformation zvivakwa, inogona kuve nani kune inopisa kudzvanywa kugadzirisa, inogona kudzimwa, kuchembera kusimbisa alloy. Iyo simba mushure mekupisa kurapwa inenge 50% ~ 100% yakakwirira kupfuura iyo mushure mekuvhara; Kusimba kwekushisa kwepamusoro, kunogona kushanda mu400 ℃ ~ 500 ℃ tembiricha kwenguva yakareba, kugadzikana kwayo kwekushisa kwakaderera kune α titanium alloy.

Pakati pematatu matatu etitanium, anonyanya kushandiswa ndeye α titanium alloy uye α + β titanium alloy; Kucheka kushanda kwe α titanium alloy ndiyo yakanakisisa, inoteverwa ne α + β titanium alloy, uye β titanium alloy ndiyo yakaipisisa. α titanium alloy code yeTA, β titanium alloy code yeTB, α+β titanium alloy code yeTC.

Titanium alloy inogona kukamurwa kuita kupisa kusingachinji alloy, yakakwirira simba alloy, ngura isingachinji alloy (titanium - molybdenum, titanium - palladium alloy, nezvimwewo), yakaderera tembiricha alloy uye yakakosha basa alloy (titanium - iron hydrogen kuchengetedza zvinhu uye titanium - nickel ndangariro. alloy). Kuumbwa uye zvimiro zveakajairika alloys zvinoratidzwa mutafura.

Different phase compositions and microstructure of heat-treated titanium alloys inogona kuwanikwa nekugadzirisa kupisa kwekupisa. Zvinowanzotendwa kuti yakanaka equiaxed zvimiro zvine nani plastiki, kugadzikana kwekupisa uye kuneta simba. Iyo spiculate chimiro chine kusimba kwakanyanya, kusimba simba uye kutsemuka kuoma. Equiaxial uye tsono-senge yakasanganiswa matishu ane zviri nani akazara zvivakwa. Titanium rudzi rutsva rwesimbi, kushanda kwetitanium kwakabatana nezviri mukati kabhoni, nitrogen, hydrogen, okisijeni uye kumwe kusvibiswa, iyo yakachena titanium iodide tsvina yemukati haisi kupfuura 0.1%, asi simba rayo rakaderera, rakakwirira plastiki. .

Zvimiro zve99.5% zveindasitiri pure titanium ndizvo zvinotevera: density ρ=4.5g/ cubic cm, melting point 1725℃, thermal conductivity λ=15.24W/(mK), tensile simba σb=539MPa, elongation δ=25%, chikamu shrinkage ψ=25%, elastic modulus E=1.078×105MPa, kuoma HB195. Kuwanda kwetitanium alloy inowanzoita 4.51g/ cubic centimita, 60% chete yesimbi, simba retitanium yakachena riri pedyo nekusimba kwesimbi yakajairwa, imwe yakasimba simba titanium alloy inodarika simba reakawanda alloy structural simbi. Nokudaro, iyo chaiyo simba (simba / density) yetitanium alloy yakakura zvikuru kupfuura yeimwe simbi yekugadzira zvinhu, sezvinoratidzwa muTebhu 7-1. Inogona kuburitsa zvikamu uye zvikamu zvine simba repamusoro reyuniti, kusimba kwakanaka uye huremu huremu. Parizvino, titanium alloys inoshandiswa muzvikamu zveinjini, skeleton, ganda, fasteners uye giya rekumhara.

Tumira meseji yako kwatiri:

-

Aluminium CNC Machining Zvikamu

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining Zvikamu

-

CNC Machina Zvikamu zveItari

-

CNC Machining Aluminium Zvikamu

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

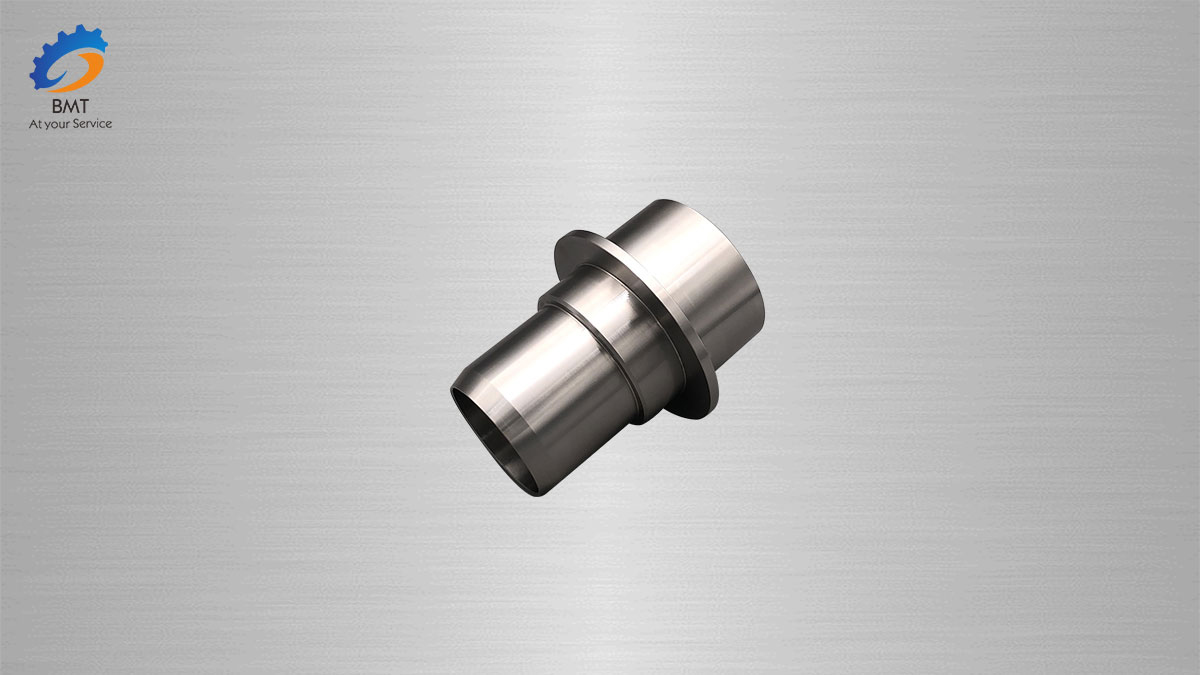

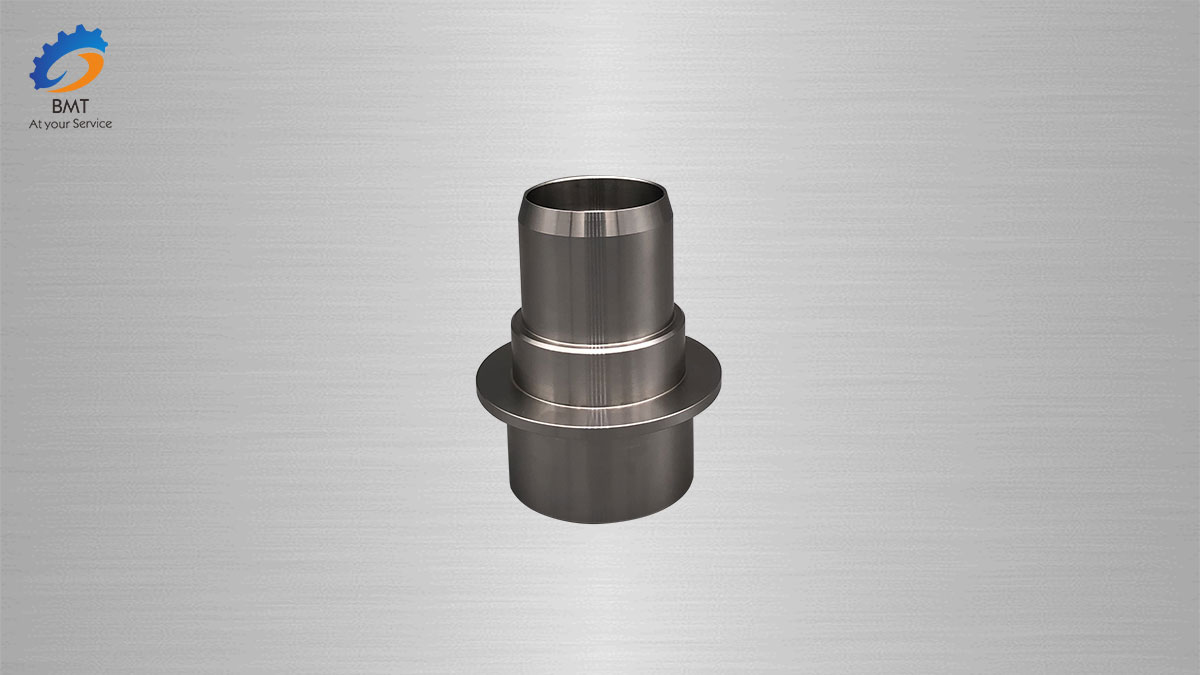

Titanium uye Titanium Alloy Fittings

-

Titanium uye Titanium Alloy Forgings

-

Titanium uye Titanium Alloy Waya

-

Titanium Bars

-

Titanium Seamless Pipes / Tubes

-

Titanium Welded Pipes/Tubes