Titanium Machining Matambudziko

(1) Iyo deformation coefficient idiki:

Ichi chinhu chiri pachena mune machining etitanium alloy zvinhu. Mukati mekucheka, nzvimbo yekubatana pakati pe chip nerake face yakakura kwazvo, uye kurova kwechiputi pane raki chiso chechishandiso chakakura kupfuura icho chezvakawanda. Kufamba kwenguva refu kwakadaro kuchaita kuti chimbo chakakomba chipfeke, uye Friction inoitikawo panguva yekufamba, iyo inowedzera kutonhora kwechishandiso.

(2) Kupisa kwakanyanya kwekucheka:

Kune rumwe rutivi, iyo diki deformation coefficient yataurwa pamusoro inotungamira kune chikamu chekuwedzera kwekushisa. Chinhu chikuru chepamusoro chekucheka tembiricha mu titanium alloy yekucheka maitiro ndechekuti thermal conductivity yetitanium alloy idiki kwazvo, uye kureba kwekubatana pakati pe chip uye raki chiso chechishandiso ipfupi.

Pasi pesimba rezvinhu izvi, kupisa kunogadzirwa panguva yekucheka kunonetsa kuendesa kunze, uye inonyanya kuunganidza pedyo nepamusoro pechishandiso, zvichiita kuti kupisa kwenzvimbo kuve kwakanyanya.

(3) Thermal conductivity yetitanium alloy yakaderera zvikuru:

Kupisa kunokonzerwa nekucheka hakusi nyore kupera. Kushandura nzira yetitanium alloy inzira yekushungurudzika kukuru uye kushungurudza kukuru, izvo zvichaunza kupisa kwakawanda, uye kupisa kwakanyanya kunogadzirwa panguva yekugadzirisa hakugone kuparadzirwa zvakanaka. Pablade, tembiricha inokwira zvakanyanya, blade inopfava, uye kupfeka kwechombo kunowedzera.

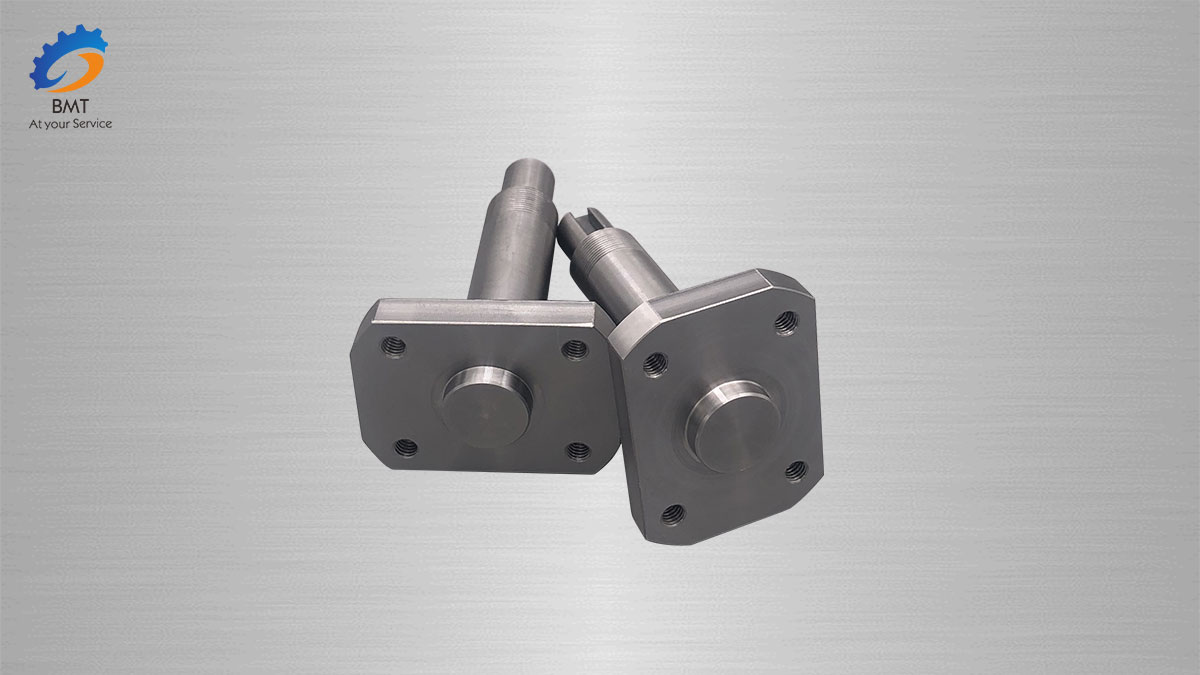

Iyo chaiyo simba retitanium alloy zvigadzirwa zvakakwirira zvakanyanya pakati pesimbi zvimiro zvesimbi. Simba rayo rakafanana neresimbi, asi huremu hwayo hunongova 57% yesimbi. Pamusoro pezvo, titanium alloys ine hunhu hwehudiki hwakasimba hwemagetsi, kusimba kwekushisa kwepamusoro, kugadzikana kwakanaka kwekupisa uye kushorwa, asi titanium alloy zvinhu zvakaoma kucheka uye zvine kushomeka kwekugadzirisa. Naizvozvo, maitiro ekukunda kuoma uye kuderera kwekuita kwetitanium alloy processing yagara iri dambudziko rekukurumidzira kugadziriswa.

Tumira meseji yako kwatiri:

-

Aluminium CNC Machining Zvikamu

-

Aluminium Sheet Metal Fabrication

-

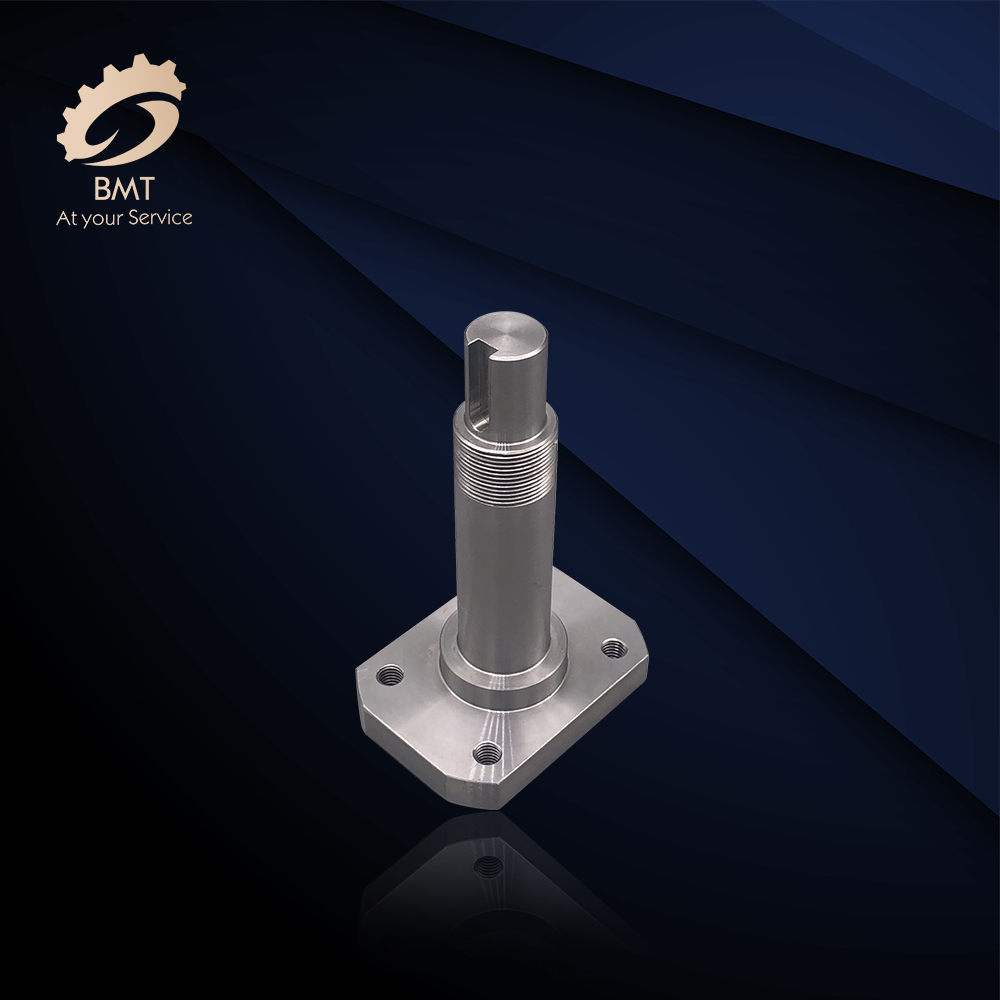

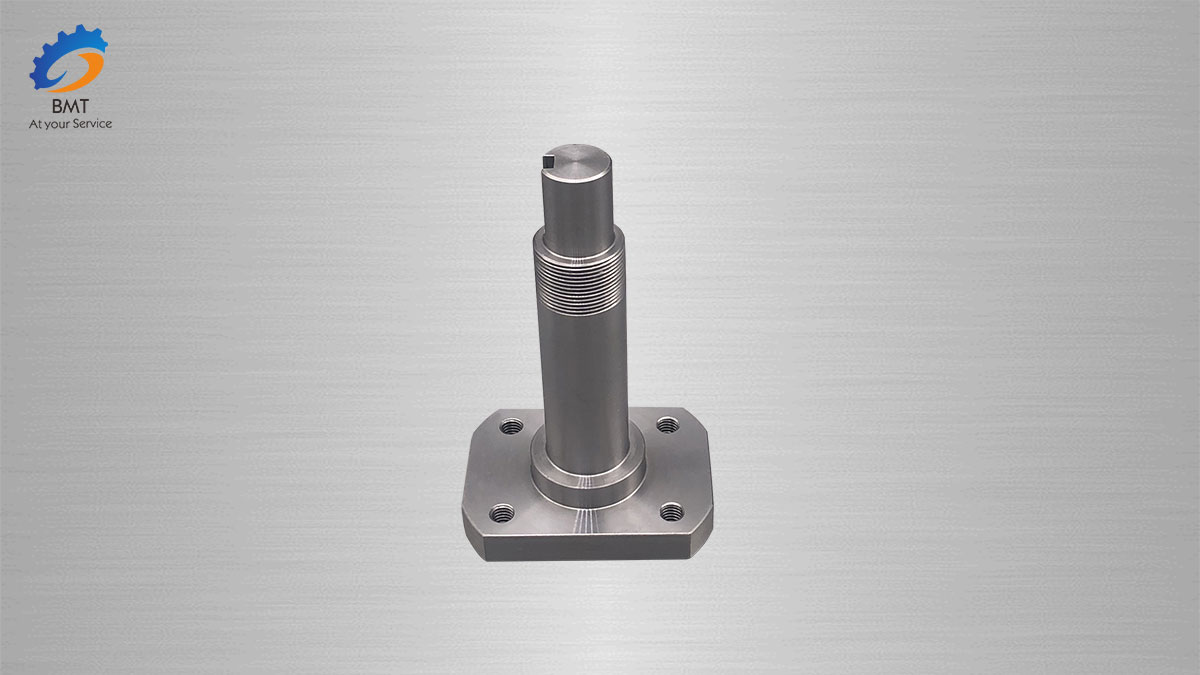

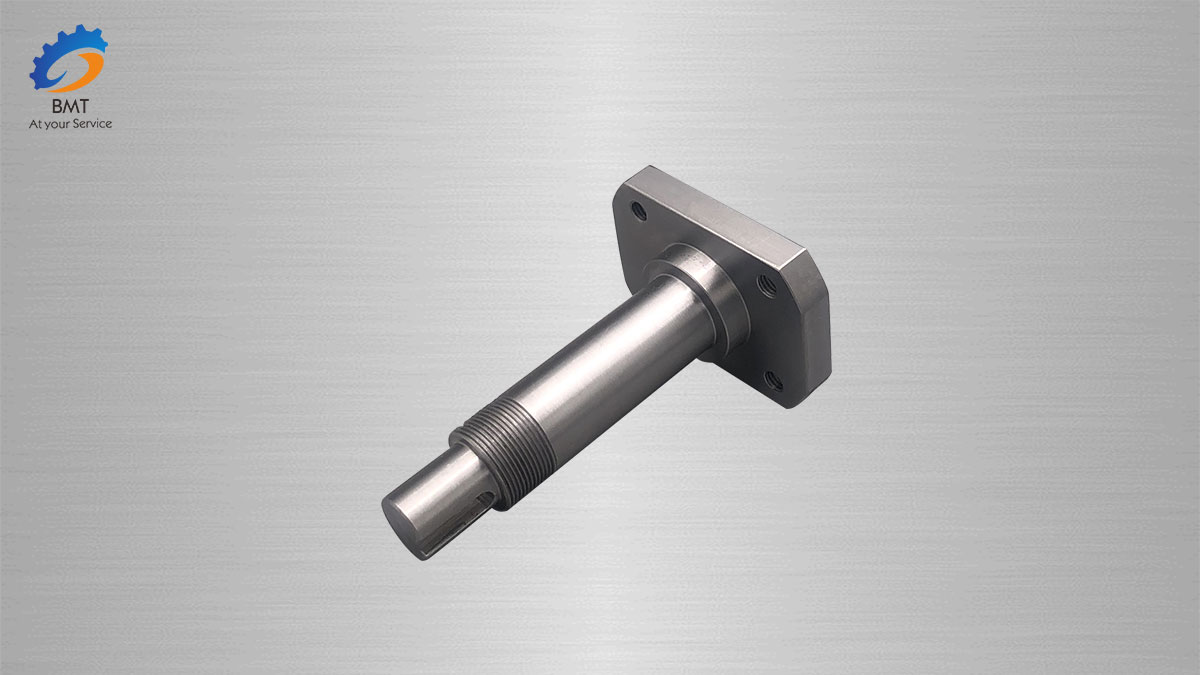

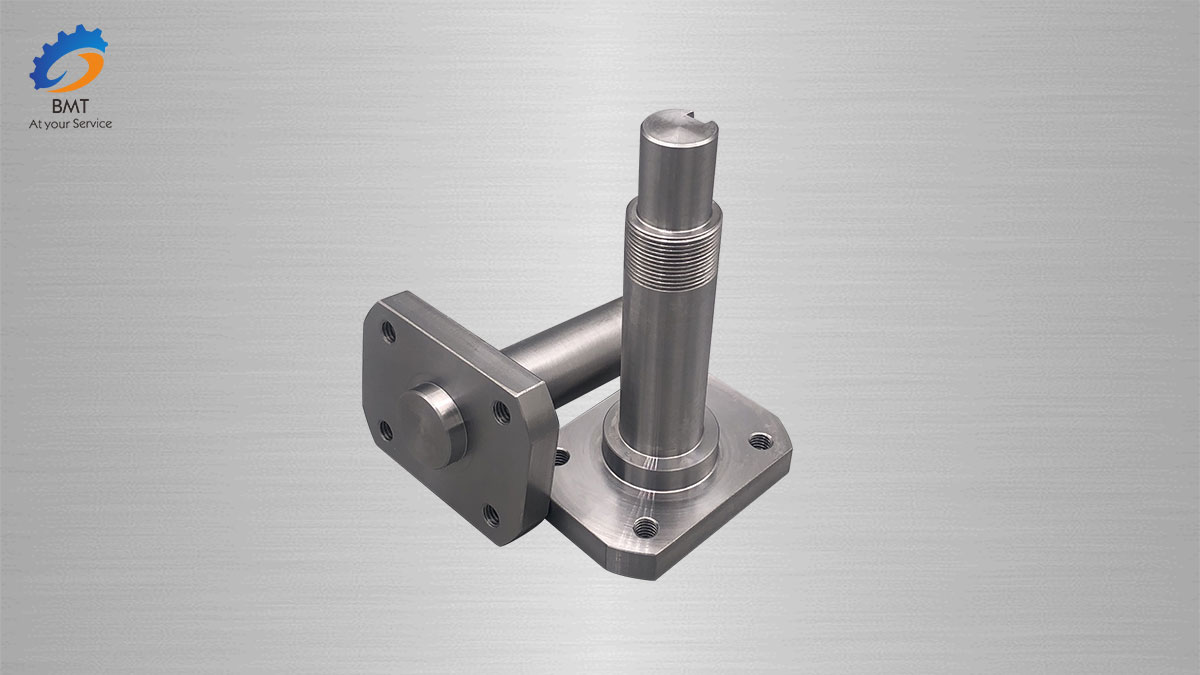

Axis High Precision CNC Machining Zvikamu

-

CNC Machina Zvikamu zveItari

-

CNC Machining Aluminium Zvikamu

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium uye Titanium Alloy Fittings

-

Titanium uye Titanium Alloy Forgings

-

Titanium uye Titanium Alloy Waya

-

Titanium Bars

-

Titanium Seamless Pipes / Tubes

-

Titanium Welded Pipes/Tubes