Titanium Machining Matambudziko

Iyo yekupisa conductivity yetitanium alloy idiki, saka tembiricha yekucheka yakakwira zvakanyanya kana uchigadzira titanium alloy. Pasi pemamiriro ezvinhu akafanana, kupisa kwekucheka kwekugadzirisa TC4 [i] kunopfuura kaviri yeNo. Release; iyo chaiyo inopisa yetitanium alloy idiki, uye tembiricha yemuno inokwira nekukurumidza panguva yekugadzira. Naizvozvo, tembiricha yechishandiso chakanyanya kukwirira, tipi rekushandisa rinopfekwa zvakanyanya, uye hupenyu hwebasa hunoderedzwa.

Iyo yakaderera elastic modulus yetitanium alloy[ii] inoita kuti iyo yakashongedzwa pamusoro iite kuti iite springback, kunyanya machining ezvikamu zvakatetepa-ane madziro zvakakomba, zviri nyore kukonzeresa kukweshana kwakasimba pakati peflank nenzvimbo yakagadzirwa, nekudaro kupfeka chishandiso uye. chipping. blade.

Titanium alloy ine simba remakemikari basa, uye zviri nyore kushamwaridzana neokisijeni, hydrogen uye nitrogen pakupisa kwepamusoro, iyo inowedzera simba rayo uye inoderedza plastiki yayo. Iyo oksijeni-yakapfuma layer inoumbwa panguva yekudziya uye kuforoma inoita kuti machining akaoma.

Machining misimboti yetitanium alloy zvinhu[1-3]

Mukuita machining, iyo yakasarudzwa chishandiso zvinhu, mamiriro ekucheka uye nguva yekucheka zvinokanganisa kushanda uye hupfumi hwetitanium alloy yekucheka.

1. Sarudza chinhu chine musoro chekushandisa

Zvinoenderana nezvivakwa, nzira dzekugadzirisa uye kugadzirisa tekinoroji mamiriro etitanium alloy zvinhu, zvishandiso zvekushandisa zvinofanirwa kusarudzwa zvine musoro. Chishandiso chemidziyo chinofanirwa kusarudzwa chinowanzo shandiswa, mutengo wakaderera, kunaka kupfeka kuramba, kuomarara kwemafuta, uye kune kuoma kwakakwana.

2. Kuvandudza mamiriro ekucheka

Iko kuomarara kwemuchina-kugadzirisa-chishandiso system kuri nani. Kubvumidzwa kwechikamu chimwe nechimwe chechishandiso chemuchina kunofanirwa kugadziridzwa zvakanaka, uye radial runout ye spindle inofanira kunge iri diki. Iyo clamping basa rekugadzirisa rinofanira kunge rakasimba uye rakasimba zvakakwana. Chikamu chekucheka chechishandiso chinofanira kunge chiri chipfupi sezvinobvira, uye hupamhi hwekucheka hunofanira kuwedzerwa zvakanyanya sezvinobvira apo kushivirira kwechip kunokwana kuvandudza simba uye kusimba kwechigadzirwa.

3. Kurapa kwakakodzera kwekupisa kwezvinhu zvakagadziriswa

Izvo zvinhu uye metallographic chimiro chetitanium alloy zvinhu zvinoshandurwa nekupisa kurapwa [iii], kuitira kuvandudza machinability yezvinhu.

4. Sarudza chiyero chakanaka chekucheka

Kucheka kumhanya kunofanira kunge kwakaderera. Nekuti kukurumidza kwekucheka kune simba guru pakupisa kwekucheka kwekucheka, iyo yakakwirira yekucheka kukurumidza, kuwedzera kwakanyanya kwekushisa kwekucheka kwekucheka, uye kupisa kwekucheka kwekucheka kunobata zvakananga hupenyu hwechishandiso, saka zvakakosha kusarudza kukurumidza kucheka kwakakodzera.

Tumira meseji yako kwatiri:

-

Aluminium CNC Machining Zvikamu

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining Zvikamu

-

CNC Machina Zvikamu zveItari

-

CNC Machining Aluminium Zvikamu

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium uye Titanium Alloy Fittings

-

Titanium uye Titanium Alloy Forgings

-

Titanium uye Titanium Alloy Waya

-

Titanium Bars

-

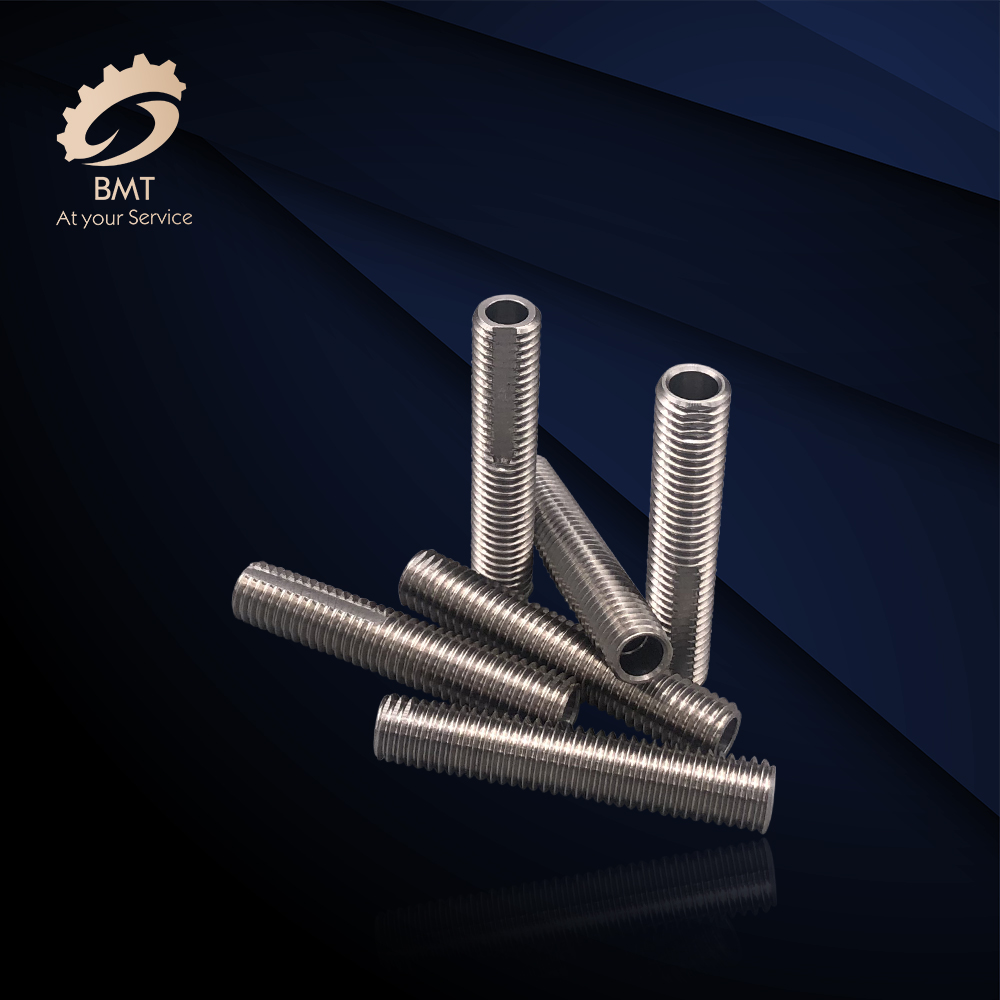

Titanium Seamless Pipes / Tubes

-

Titanium Welded Pipes/Tubes