Titanium Plate, Sheet uye Coil

Titanium Plate Manufacturing Process

Kupisa Forging Maitiro ekuumba umo simbi inodzokororwa pamusoro petembiricha.Hot rolling Maitiro ekukunguruka pane tembiricha pamusoro pe recrystallization.Cold rolling process umo tembiricha yepurasitiki deformation yakadzikira pane yekudzoreredza tembiricha.

Annealing: Nzira iyo masimbi anodziyiswa zvishoma nezvishoma kusvika kune imwe tembiricha, kwenguva yakakwana, uye yozotonhodzwa (kazhinji zvishoma nezvishoma uye dzimwe nguva inodzorwa) pamwero wakakodzera.

Pickling: Nyura chigadzirwa muine aqueous solution, senge sulfuric acid, kubvisa oxides nemamwe mafirimu akaonda pamusoro pesimbi surface.Is electroplating, enamel, rolling uye mamwe maitiro ekutanga kurapwa kana kurapwa kwepakati.

Hunhu hwetitanium plate

1. Titanium seed plate ifirimu rine oxidized pamusoro, iyo yakaenzana neakanaka kupfeka-resistant kupatsanura bvudzi. Kushandiswa kwetitanium mhodzi ndiro inochengetedza iyo yekuparadzanisa, inoita kuti ndiro ive nyore kusvuura, inobvisa maitiro ekutanga kugadzirwa kwendiro yembeu, uye ndiro yembeu yetitanium inoreruka nehafu pane ndiro yemhangura yembeu.

2. Hupenyu hwesevhisi yetitanium seed plate inodarika ka3 kupfuura yecopper seed plate, inogona kusvika makore gumi kusvika makumi maviri zvichienderana nemamiriro ekushanda.

3. Electrolytic mhangura yakagadzirwa netitanium seed plate ine compact crystal structure, inotsvedzerera uye yemhando yepamusoro.

4. Nemhaka yokuti ndiro yetitanium haifaniri kuputirwa nemushandi wekuparadzanisa, inogona kudzivisa kusvibiswa kwemhangura electrolyte.

5. Kuvandudza huwandu hwekugadzira uye kuderedza mutengo wekugadzira electrolytic mhangura, kuitira kuti uwane hupfumi huri nani.

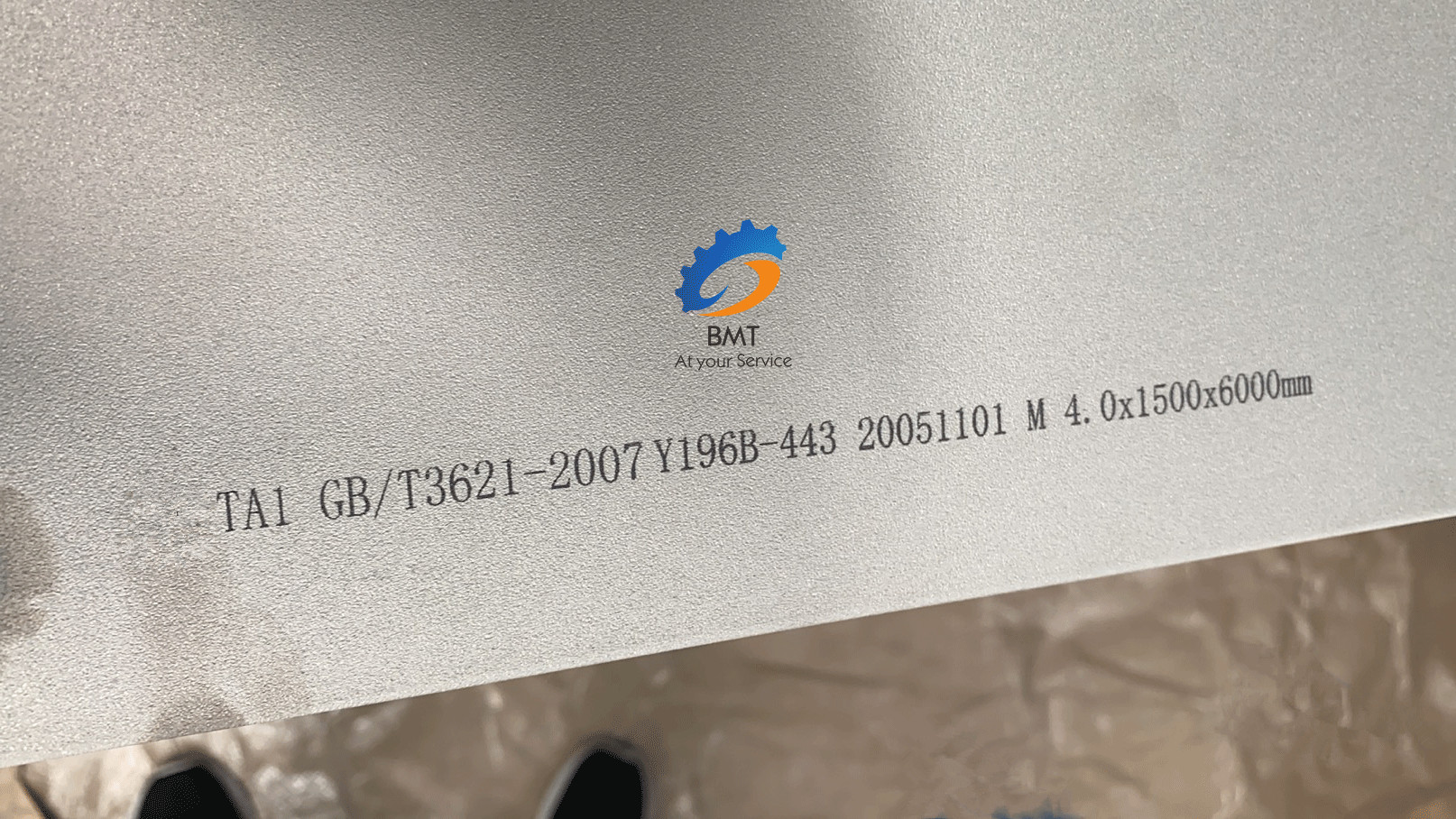

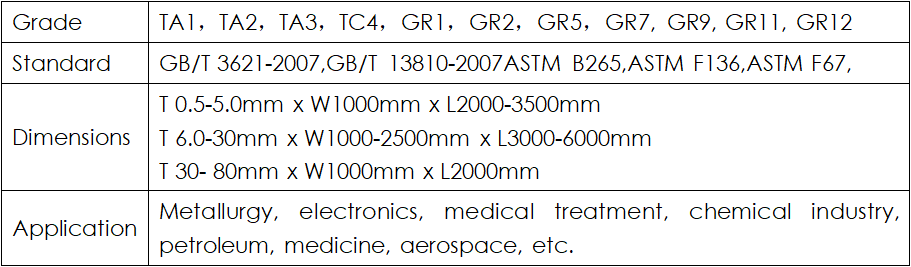

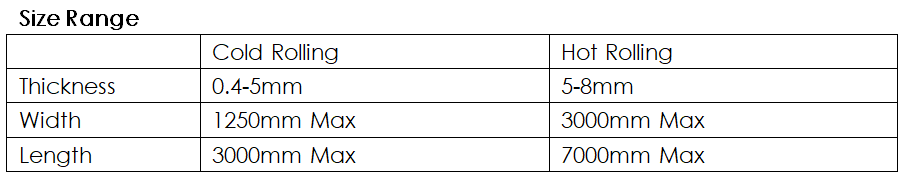

BMT renji retitanium sheet neplate rinowanzo gadzirwa zvinoenderana nezviyero zvakaita seASTM/ASME B/SB265, ASTM F136, ASTM F67, AMS 4911, uye AMS4900.

BMT's gore negore kugadzirwa kwetitanium mashiti uye paltes i10000 matani, kusanganisira mazana maviri ematoni ePHE (Plate for heat exchanger), uye 8000 matani kune mamwe maapplication. BMT high quality titanium sheets uye mahwendefa, anosanganisira kutonhora akakungurutswa titanium mapepa uye inopisa yakakungurutswa titanium mahwendefa, ari pasi pekutariswa kwakasimba uye kutarisa maererano neyakagadzirwa-titanium sponge. BMT inodzora maitiro ese, sekunyunguduka, kuumbiridza, kupisa kukungurutswa, kutonhora kukungurutswa, kupisa kupisa, nezvimwe. Isu tinotumira kunze zvigadzirwa kutenderera pasirese uye tinokugamuchirai noushamwari kuti mushande nesu.

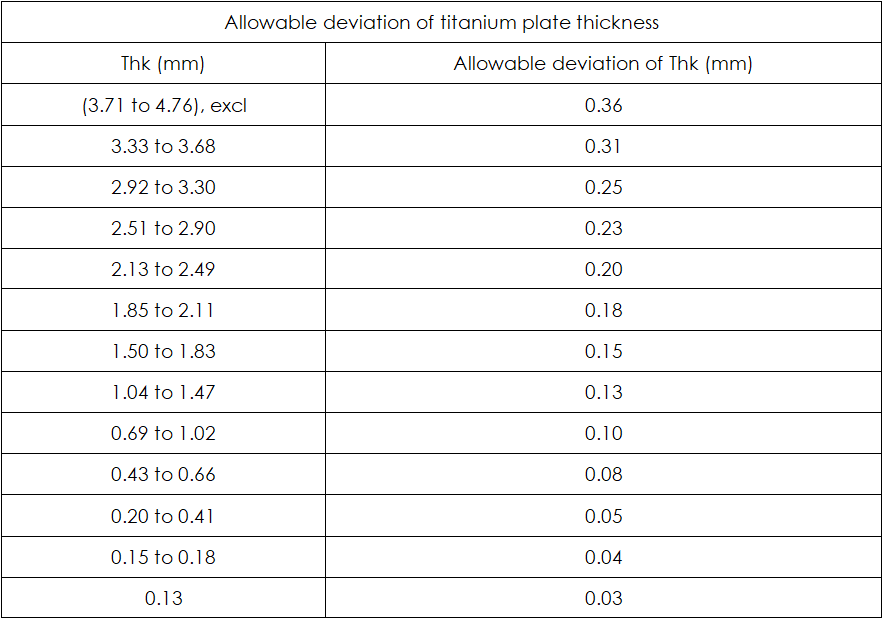

Titanium Plate Hukobvu Inotenderwa Kutsauka:

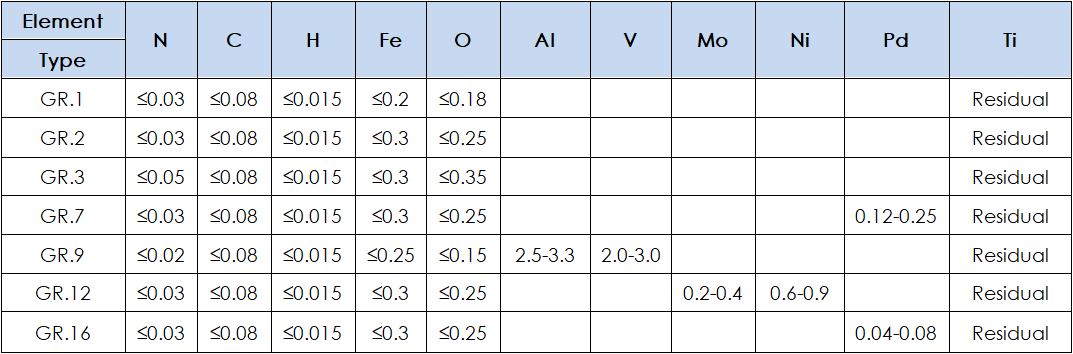

Inowanikwa Material Chemical Composition:

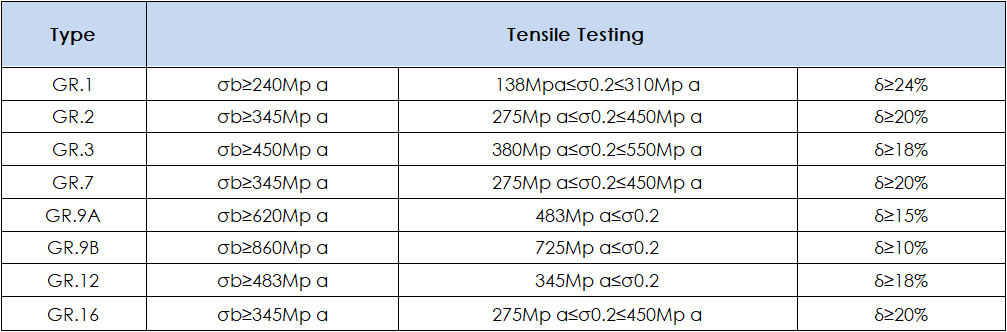

Inowanikwa Material Mechanical Property:

Inspection test:

- Chemical Composition Analysis

- Mechanical Property Test

- Tensile Testing

- Flaring Test

- Flattening Test

- Bending Test

- Hydro-Static Test

- Pneumatic Test (Air pressure test pasi pemvura)

- NDT Test

- Eddy-Yazvino Muedzo

- Ultrasonic Test

- Muedzo weLDP

- Ferroxyl Test

Kugadzirwa (Max uye Min huwandu hweOdha):Unlimited, maererano nehurongwa.

Nguva Yekutungamira:Nguva yekufambisa yakawanda mazuva makumi matatu. Nekudaro, zvinoenderana nehuwandu hweiyo odha zvinoenderana.

Zvekufambisa:Iyo yakajairika nzira yekufambisa ndeyeGungwa, neMhepo, ne Express, neChitima, iyo ichasarudzwa nevatengi.

Packing:

- Pombi inopera kuchengetedzwa nepurasitiki kana kadhibhodhi zvivharo.

- Zvese zvigadziriso zvinofanirwa kurongedzerwa kudzivirira magumo uye kutarisana.

- Zvimwe zvinhu zvese zvichange zvakazara nemafuro pads uye zvine chekuita nepurasitiki kurongedza uye makesi eplywood.

- Chero huni hunoshandiswa kurongedza hunofanirwa kuve hwakakodzera kudzivirira kusvibiswa nekusangana nemidziyo yekubata.