Titanium uye Titanium Alloy Forgings

Titanium uye titanium alloys ane zvakanakira kushoma density, yakakwirira chaiyo simba uye yakanaka corrosion resistance, uye anoshandiswa zvakanyanya munzvimbo dzakasiyana siyana.

Titanium forging inzira yekugadzira iyo inoshandisa simba rekunze kune titanium metal blanks (Kusingabatanidzi mahwendefa) kugadzira mapurasitiki deformation, kushandura saizi, chimiro, uye kugadzirisa mashandiro. Inoshandiswa kugadzira mekiniki zvikamu, maworkpiece, maturusi kana ma blanks. Pamusoro pezvo, zvinoenderana nemafambiro emusevedzero uye yakatwasuka uye yakachinjika mafambiro eiyo inotsvedza (Nekuda kugadzira zvidimbu zvitete, mafuta ekuzora uye kutonhora, uye kuumbwa kweakakwira-kumhanya zvikamu zvekugadzira), mamwe mafambiro anogona kuwedzerwa ne. kushandisa mudziyo wekuripa.

Idzi nzira dziri pamusoro dzakasiyana, uye iyo inodiwa yekusimbisa simba, maitiro, chiyero chekushandisa zvinhu, kuburitsa, dimensional kushivirira, uye lubrication uye kutonhora nzira dzakasiyana. Izvi zvinhu zvakare zvinhu zvinokanganisa mwero we automation.

Forging inzira yekushandisa iyo plasticity yesimbi kuwana mapurasitiki ekuumba maitiro ane chimwe chimiro uye maumbirwo ezvimiro zveasina chinhu pasi pekukanganisa kana kudzvanywa kwechishandiso. Iko hukuru hwekugadzira kugadzirwa ndeyekuti haingogone chete kuwana chimiro chemechini zvikamu, asi zvakare kuvandudza chimiro chemukati chechinhu uye kugadzirisa ma mechanika ezvikamu zvemakanika.

1. Free Forging

Forging yemahara inowanzoitwa pakati pemafurati maviri anofa kana mold pasina mhango. Zvishandiso zvinoshandiswa mukugadzira mahara zviri nyore muchimiro, zvinochinjika, zvipfupi mukugadzira kutenderera uye zvakaderera mumutengo. Nekudaro, kusimba kwevashandi kwakakwira, kushanda kwakaoma, kugadzirwa kwakaderera, mhando yefogi haina kukwirira, uye machining mvumo yakakura. Nokudaro, yakakodzera chete kushandiswa kana pasina zvakakosha zvinodiwa pakushanda kwezvikamu uye nhamba yezvidimbu zviduku.

2. Vhura Die Forging (Die Forging with Burrs)

Iyo isina chinhu yakakanganiswa pakati pemamodule maviri ane cavities akavezwa, iyo yekugadzira inovharirwa mukati megomba, uye iyo yakawandisa simbi inoyerera ichibuda kubva pakamanikana pakati pezviviri zvinofa, zvichigadzira maburrs akatenderedza forging. Pasi pekupikiswa kwemuumbi uye mabhero akapoteredzwa, simbi inomanikidzwa kumanikidzwa muchimiro chegomba rekuumbwa.

3. Yakavharwa Die Forging (Die Forging isina Burrs)

Munguva yakavharwa yekufa forging process, hapana transverse burrs perpendicular kudivi rekufa mafambiro anoumbwa. Iyo mhango yeyakavharwa yefogi yekufa ine mabasa maviri: imwe ndeyekugadzira isina chinhu, uye imwe ndeyekutungamira.

4. Extrusion Die Forging

Uchishandisa extrusion nzira yekufa forging, kune marudzi maviri efogi, yekumberi extrusion uye reverse extrusion. Extrusion die forging inogona kugadzira akasiyana maburi uye akasimba zvikamu, uye inogona kuwana forgings ine yakakwirira geometrical chaiyo uye denser yemukati chimiro.

5. Multi-Directional Die Forging

Iyo inoitwa pamushini we-multi-directional die forging muchina. Kuwedzera kune yakatwasuka punching uye plug jekiseni, iyo yakawanda-directional die forging muchina zvakare ine maviri akatwasuka plungers. Iyo ejector yayo inogona zvakare kushandiswa pakurova. Kudzvanywa kweiyo ejector kwakakwira kupfuura kweyakajairika hydraulic press. Kuva mukuru. Mu-multi-directional die forging, inotsvedza inoita zvakachinjika uye yakabatana pane yebasa kubva kune yakatwasuka uye yakachinjika nzira, uye imwe kana anopfuura mabhanhire ekuputira anoshandiswa kuita kuti simbi ibude ichibuda nepakati pegomba kuzadzisa chinangwa chekuzadza iyo. mhango.

6. Divided Forging

Kuti ugadzire mahombe akabatanidzwa ekugadzira pane iripo hydraulic pressure, segmental die forging nzira dzakadai sechikamu kufa forging uye shim plate die forging inogona kushandiswa. Icho chimiro chechidimbu chekufa chekugadzira nzira ndechekugadzira chidimbu chekugadzira nechidimbu, kugadzirisa chikamu chimwe panguva, saka iyo inodiwa yemidziyo tonnage inogona kuve diki. Kazhinji kutaura, iyi nzira inogona kushandiswa kugadzira yakawedzera-yakakura forgings pane yepakati-saizi hydraulic presses.

7. Isothermal Die Forging

Asati agadzira, mold inodziirwa kune tembiricha yekugadzira isina chinhu, uye tembiricha ye mold uye isina chinhu inoramba yakafanana panguva yese yekugadzira, kuitira kuti huwandu hukuru hwe deformation huwanikwe pasi pechiito chesimba diki deformation. . Isothermal die forging uye isothermal superplastic die forging dzakanyanya kufanana, mutsauko ndewekuti kufa kwekugadzira, iyo isina chinhu inoda kuve superplasticized [i] kuti iite yakaenzana tsanga [ii].

Titanium alloy forging process inoshandiswa zvakanyanya mukugadzirwa kwendege uye aerospace (Isothermal Die Forging Processyakashandiswa mukugadzira zvikamu zveinjini uye zvikamu zvezvimiro zvendege), uye iri kuramba ichizivikanwa mumaindasitiri akadai semotokari, simba remagetsi, uye ngarava.

Parizvino, mutengo wekushandisa wetitanium zvinhu wakakwira, uye minda yakawanda yevagari vemo haisati yanyatsoona kunaka kwetitanium alloys. Nekuenderera mberi kwekufambira mberi kwesainzi, kugadzirira kwetitanium uye titanium alloy chigadzirwa tekinoroji ichave nyore uye mutengo wekugadzirisa uchave wakadzikira uye wakadzikira, uye runako rwetitanium uye titanium alloy zvigadzirwa zvicharatidzwa munzvimbo dzakasiyana siyana.

Using extrusion nzira yekufa forging, kune marudzi maviri ekugadzira, Forward Extrusion uye Reverse Extrusion. Extrusion Die Forging inogona kugadzira akasiyana maburi uye akasimba zvikamu, uye inogona kuwana forgings ine yakakwirira geometrical chaiyo uye denser yemukati chimiro.

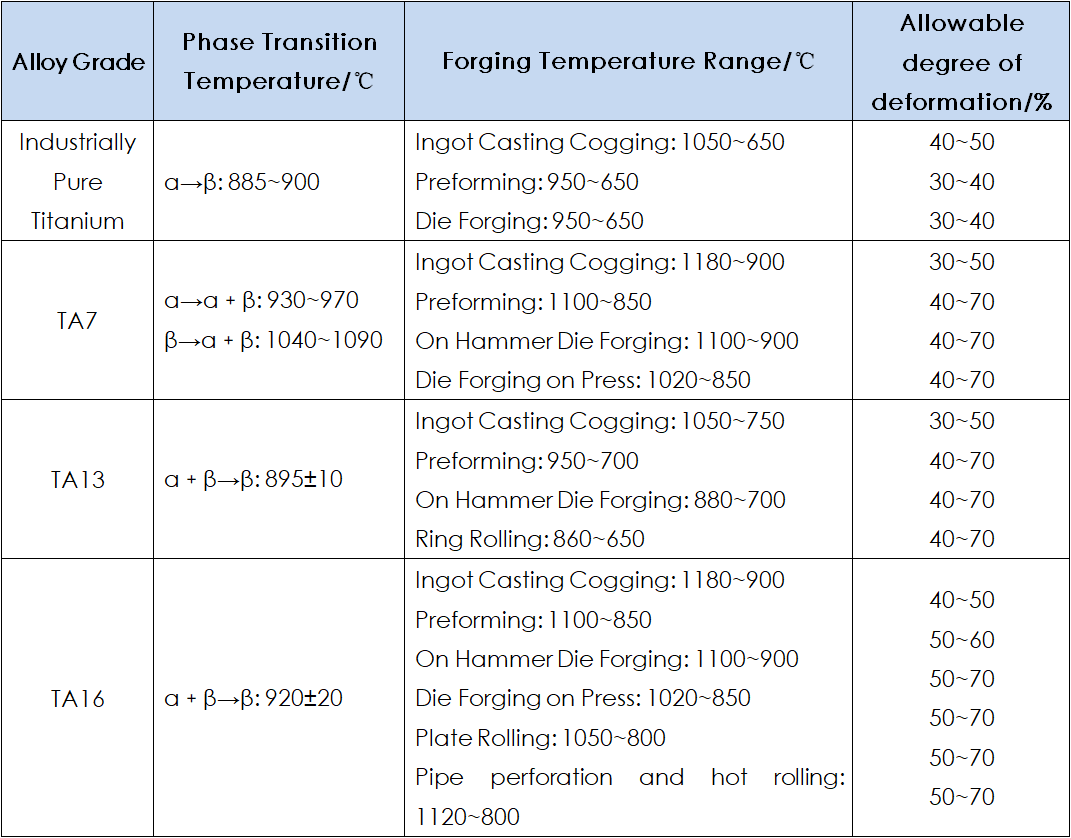

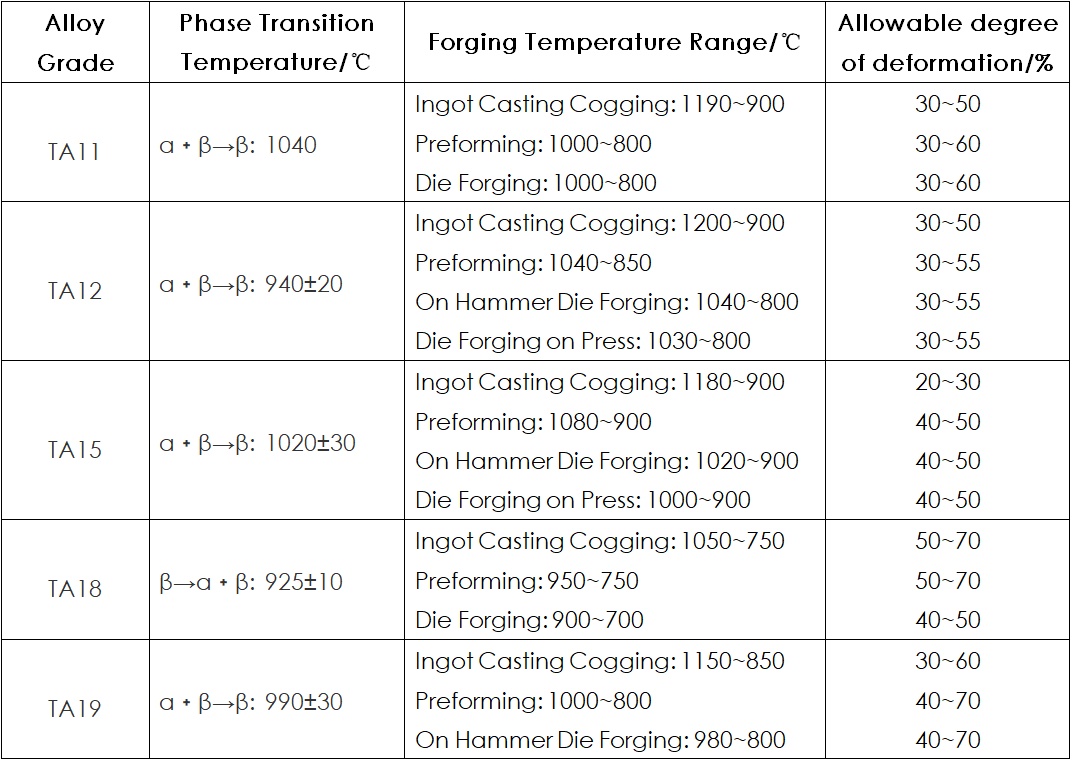

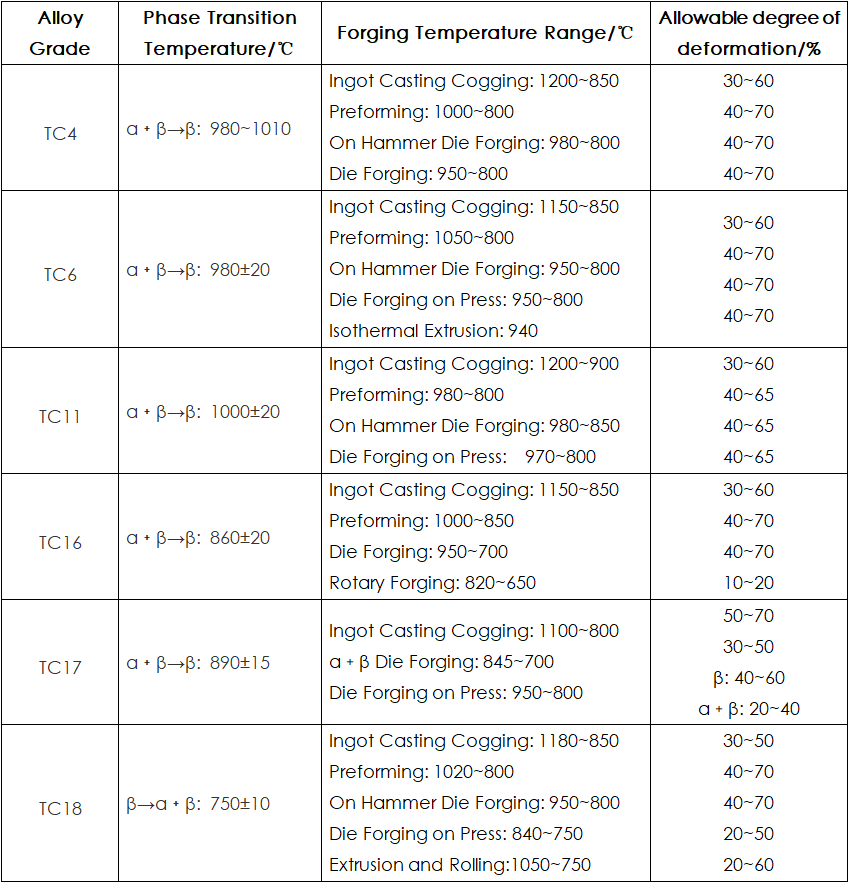

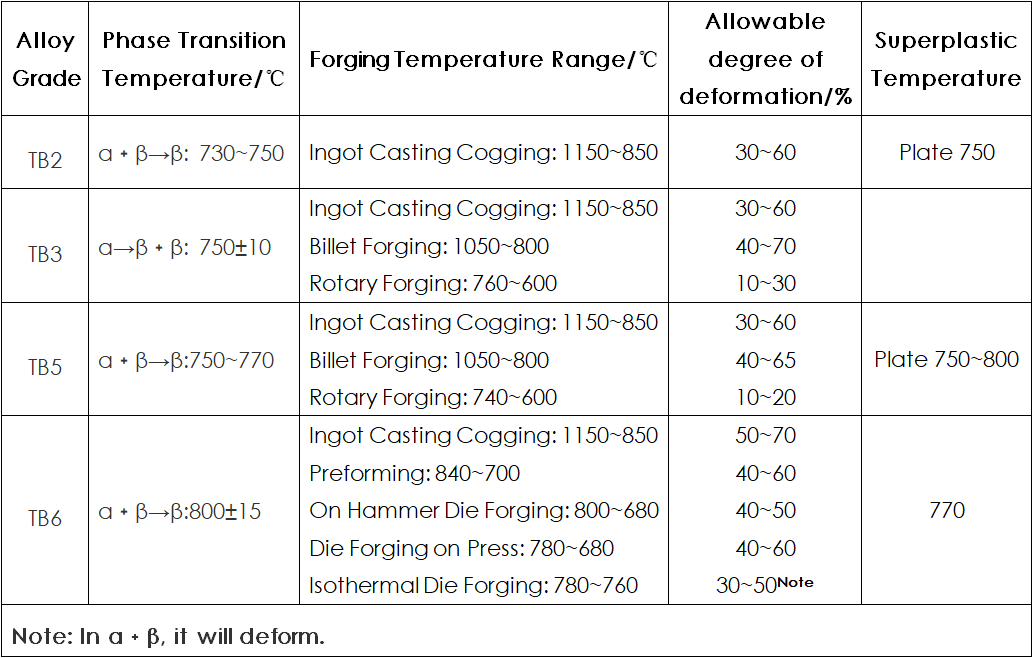

Zvinoenderana nedzidziso yekutsvagisa uye ruzivo rwekugadzira fekitori, iyo yekugadzira dhizaini data yea-mhando, pedyo-α-mhando, α﹢β-mhando uye pedyo-β-mhando titanium alloys inopfupikiswa muTafura 1 kusvika Tafura 4, zvichiteerana.

Kubva pane data iri muTable 1 kusvika Tafura 4, zvinogona kuonekwa kuti tembiricha yebilleting yeakawanda titanium alloy ingots iri pakati pe1150 ° C kusvika 1200 ° C, uye tembiricha yekutanga yekubikira yeimwe titanium alloy ingots iri mumhando. ye1050°C kusvika 1100°C; Idzi nzvimbo mbiri dzetembiricha dziri dzese dziri munzvimbo ye β chikamu, uye yekutanga yakakwira kupfuura tembiricha yekuchinja kwechikamu nekuda kwezvikonzero zvakawanda.

Kutanga, iyo alloy ine yakakwirira kuumbwa uye yakaderera deformation kuramba mu β chikamu zone. Kuti uvavarire kwenguva yakareba yekugadzira, Zvinobatsira kuvandudza chibereko; chechipiri, iyo billet yekutumbuka ingot inonyanya kupihwa senge isina chinhu yekuforoma. Mushure mekugadzira neyakakura deformation, chimiro chinogona kuvandudzwa pasina kukanganisa kuita kwekugadzira. Nokudaro, nzira ine kugadzirwa kwepamusoro inosarudzwa.

Kubva pane data iri muTebhurari 1 kusvika Tafura 4, zvinogona kuonekwa kuti tembiricha yekutanga yekubikira yekufa kwekugadzira pamuchina haina kungodzika zvakanyanya pane yekutanga kupisa tembiricha yeingot billet, asi zvakare yakaderera pane iyo α/β chikamu chekuchinja tembiricha. ne30℃~50℃. Yakawanda titanium Iyo tembiricha yekufa kweiyo alloy iri muhuwandu hwe930 ℃ ~ 970 ℃, inova yekuona deformation munharaunda ye α﹢β yechikamu kuti uwane iyo inodiwa microstructure uye zvivakwa zve forging. Sezvo kugadzira nyundo kufa kugadzira kunoda kurova kwakawanda uye nguva yekuvhiya yakareba, tembiricha yekudziya yekupisa yeyakapera kuumbwa kwayo inogona kukwidziridzwa zvakafanira ne10 ℃ ~ 20 ℃ kupfuura iyo yekudhinda. Zvisinei, kuitira kuti tive nechokwadi chekugadzirisa uye mashizha etitanium alloy apedza forgings, Naizvozvo, kupisa kwekupedzisira kwekugadzira kwekugadzira kunofanirwa kudzorwa munharaunda ye α﹢β maviri-chikamu.

Izvo zvinogona zvakare kuonwa kubva kune data riri muTebhurari 1 kusvika Tafura 4 kuti yekutanga yekubikira tembiricha yeakawanda titanium alloy preforms yakakwira zvishoma pane kana padyo nechikamu chekuchinja tembiricha. Iyo yekutanga α/β yekubikira tembiricha yeshanduko senge preforming yakadzikira pane ingot inotumbuka tembiricha, uye yakakwirira kupfuura yekutanga yekubikira tembiricha yekufa forging. Deformation mune ino tembiricha zone haingotarisi kubereka, asi zvakare inogadzirira yakanaka chimiro chekugadzira.

Tafura 1 Forging process performance data ye α-type titanium

Tafura 2 Forging process performance data yepedyo α-mhando titanium alloy

Tafura 3 Forging process performance data ye α﹢β titanium alloy

Tafura 4 Forging process performance data yepedyo ne β-type titanium alloy

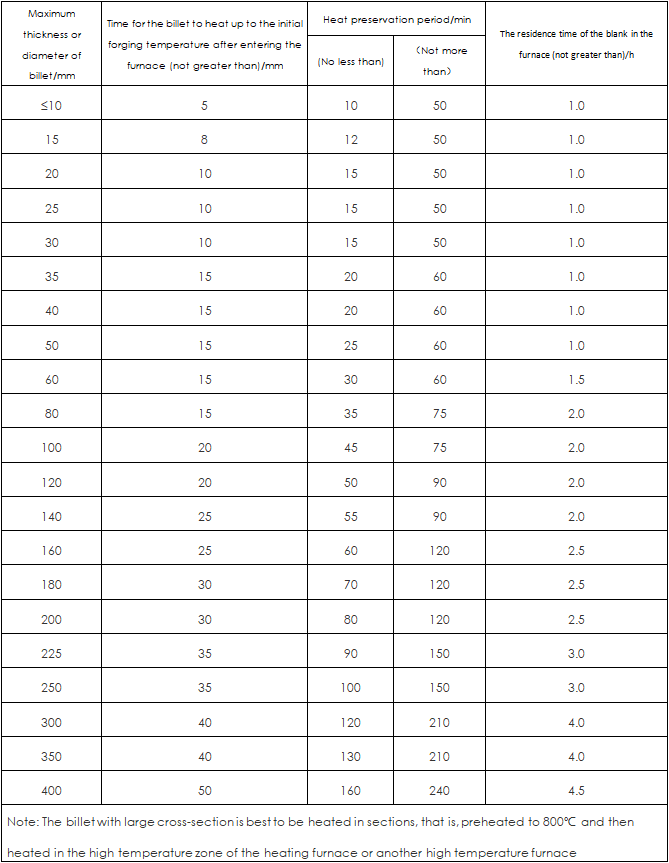

Tafura 5 Kupisa uye kubata nguva yetitanium alloy blanks

BMT inotariswa mukugadzira premium titanium forging uye titanium alloy forging ine yakanakisa mechaniki kugona, kusimba, kusaita ngura, kudzikira uye kusimba kwakanyanya. BMT titanium zvigadzirwa 'yakajairwa kugadzirwa uye nzira yekuona yakakunda zvese kuomarara kwetekinoroji uye kuoma kwekugadzira titanium kugadzira kugadzira.

Iyo yemhando yepamusoro chaiyo titanium yekugadzira yekugadzira yakavakirwa kunze kwehunyanzvi dhizaini uye zvishoma nezvishoma nzira inofambira mberi. BMT titanium forging inogona kuiswa kune renji kubva padiki skeleton inotsigira chimiro kusvika kune yakakura saizi titanium forging yendege.

BMT titanium forgings inoshandiswa zvakanyanya mumaindasitiri akawanda, akadai seaerospace, offshore engineering, mafuta uye gasi, mitambo, chikafu, mota, etc. Kuwanda kwedu kwegore kwekugadzira kunosvika ku10,000 matani.

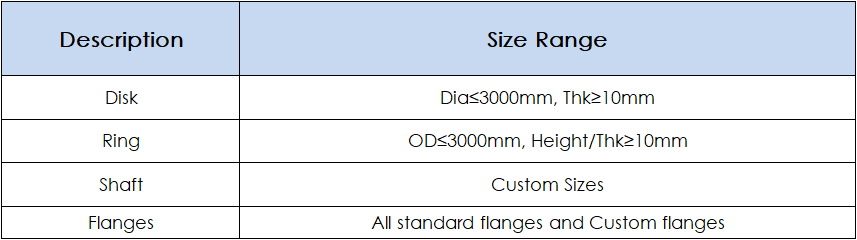

Size range:

Inowanikwa Material Chemical Composition

Inowanikwa Material Chemical Composition

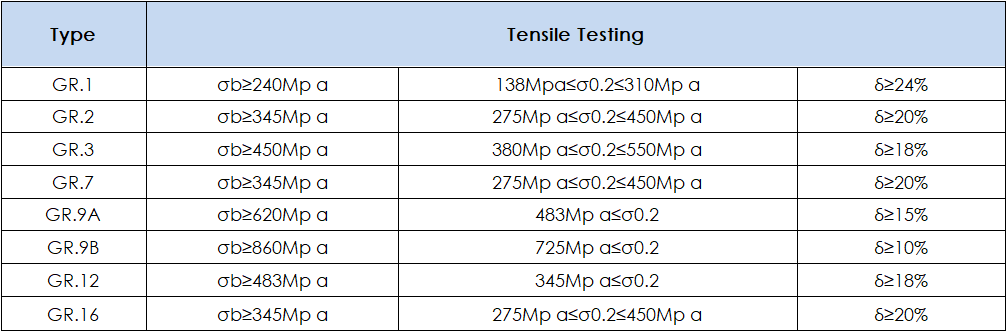

Inspection test:

- Chemical Composition Analysis

- Mechanical Property Test

- Tensile Testing

- Flaring Test

- Flattening Test

- Bending Test

- Hydro-Static Test

- Pneumatic Test (Air pressure test pasi pemvura)

- NDT Test

- Eddy-Yazvino Muedzo

- Ultrasonic Test

- Muedzo weLDP

- Ferroxyl Test

Kugadzirwa (Max uye Min huwandu hweOdha):Unlimited, maererano nehurongwa.

Nguva Yekutungamira:Nguva yekufambisa yakawanda mazuva makumi matatu. Nekudaro, zvinoenderana nehuwandu hweiyo odha zvinoenderana.

Zvekufambisa:Iyo yakajairika nzira yekufambisa ndeyeGungwa, neMhepo, ne Express, neChitima, iyo ichasarudzwa nevatengi.

Packing:

- Pombi inopera kuchengetedzwa nepurasitiki kana kadhibhodhi zvivharo.

- Zvese zvigadziriso zvinofanirwa kurongedzerwa kudzivirira magumo uye kutarisana.

- Zvimwe zvinhu zvese zvichange zvakazara nemafuro pads uye zvine chekuita nepurasitiki kurongedza uye makesi eplywood.

- Chero huni hunoshandiswa kurongedza hunofanirwa kuve hwakakodzera kudzivirira kusvibiswa nekusangana nemidziyo yekubata.