Isu tinotevera manejimendi ehutongi hwekuti "Hunhu hwakasarudzika, Mupi wepamusoro, Zita nderekutanga", uye tichagadzira nemoyo wose kubudirira nevatengi vese veManufactur standard China OEM Gadzirisa Datacom Medical Die Casting Copper Alloy Stainless Steel Alloy Steel Titanium Alloy Aluminium Alloy. Polymer Material Precision Machining, Nechokwadi tariro yekuvaka hukama hwekambani hunogara kwenguva refu newe uye isu tichaita kambani yedu yepamusoro munyaya yako.

Isu tinotevera manejimendi ehutongi hwekuti "Hunhu hwakasarudzika, Mupi wepamusoro, Zita nderekutanga", uye tichagadzira nemoyo wese kubudirira uye kugovana budiriro nevatengi vese.China OEM Die Casting, Midhudhudhu Zvishandiso, Mutengi kugutsikana ndicho chinangwa chedu chekutanga. Basa redu nderekutevera hunhu hwepamusoro, tichifambira mberi. Tinokugamuchirai nemoyo wese kuti mufambire mberi makabatana nesu, uye kuvaka ramangwana rakanaka pamwe chete.

Titanium uye Titanium Alloy Bars

Titanium alloys inogona kugoverwa muzvikamu zvitatu maererano nekuumbwa kwezvikamu: α alloy, (α + β) alloy uye β alloy, iyo inoratidzirwa neTA, TC uye TB muChina.

① Iyo α alloy ine humwe huwandu hwezvinhu zvine yakagadzikana α chikamu uye inonyanya kuumbwa α chikamu mune yakaenzana mamiriro. α alloys ane diki chaiyo giravhiti, yakanaka yekupisa simba, yakanaka weldability uye yakanakisa corrosion kuramba. Kukanganisa isimba rakaderera pakushambidzika kwekamuri, uye rinowanzoshandiswa sechinhu chinopisa uye chinopesana nekuora.Muzhinji, α alloys inogona kukamurwa kuva yakazara α alloys (Ta7), inenge α alloys (Ti-8Al-1Mo-1V) uye α alloys ane mashoma makomisheni (Ti-2.5Cu).

② (α + β) alloy ine humwe huwandu hwezvinhu zvakagadzikana α chikamu uye β chikamu, uye microstructure yealloy mumamiriro ekuenzanisa ndeye α chikamu uye β chikamu.I (α + β) alloy ine simba rine mwero uye inogona kuva yakasimbiswa nekurapa kwekupisa, asi iyo weldability yakashata.(α+ β) alloys anoshandiswa zvakanyanya, uye kubuda kweTi-6Al-4V alloys account kune inopfuura hafu yezvose titanium zvinhu.

① β alloy ine nhamba huru yezvinhu zvakagadzikana β phase, tembiricha yepamusoro β chikamu chinogona kuchengetwa kusvika kune kamuri tembiricha.β alloy inogona kukamurwa kuita heat inorapika β alloy (metastable β alloy uye inenge metastable β alloy) uye kupisa kugadzikana β alloy. Iyo inopisa-inogadziriswa β alloy ine ductility yakaisvonaka mumamiriro ekudzima uye inogona kuwana simba rekugadzirisa 130 ~ 140kgf / mm2 nekurapa kwekukwegura.β alloys inowanzoshandiswa sesimba rakakwirira uye yakakwirira kuoma zvinhu.Kuipa kwakakosha, kudhura kwakanyanya, kusina kunaka kwekushongedza. kuita, machining matambudziko.

Citation mitemo

1: GB 228 Metallic tensile bvunzo nzira

2: GB/T 3620.1 Titanium uye titanium alloy giredhi uye chimiro chemakemikari

3: GB/T3620.2 titanium uye titanium alloy kugadzirisa zvigadzirwa makemikari kuumbwa uye kuumbwa kunotenderwa kutsauka

GB 4698 Nzira dzekuongorora makemikari etitanium sponge, titanium uye titanium alloys

GB: GB/T2965-2007, GB/T13810, Q/BS5331-91

American mwero: ASTM B348, ASTM F136, ASTM F67, AMS4928

Technical zvinodiwa

1: Kemikari yetitanium uye titanium alloy bars ichaenderana nezvinodiwa zveGB/T 3620.1. Kana kudzokororwa kuyedzwa kuchidikanwa, kutsauka kunobvumirwa kwemakemikari kunoenderana nezvinodiwa zveGB/T 3620.2.

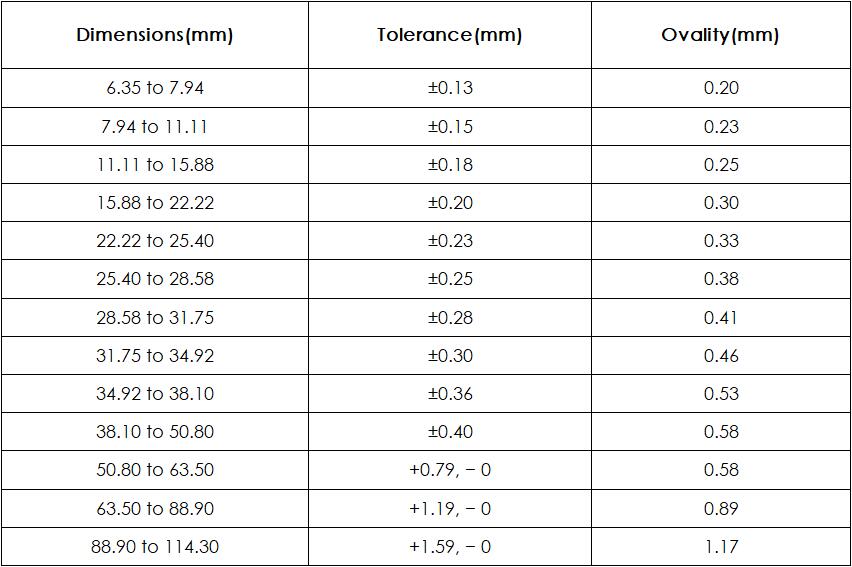

2: Iyo dhayamita kana mativi kureba kwebhari yekushanda inopisa uye kutsauka kwayo kunobvumirwa kunoenderana nezvinodiwa muTebhu 1.

3: Mushure mekushanda kunopisa, dhayamita inotenderwa kutsauka kwebhawa inotonhorera ichaenderana nezvinodiwa muTable 2 mushure mekukungurutsa (kuya) bhara rakakwenenzverwa uye kutonhora kutenderedza.

4: mushure mekupisa kupisa nemotokari (kukuya) bhari yemwenje yekutenderera haifanire kunge yakakura kupfuura hafu yehukuru hwekushivirira.

5: kureba kwehurefu husingaverengeki hwebhawa yehurumende yakagadziriswa ndeye 300-6000mm, kureba kwehurefu husingaverengeki hwebhari yehurumende yakagadziriswa ndeye 300-2000mm, uye kureba kwehurefu hwakatarwa kana hurefu huviri hunofanira kunge huri mukati mehurefu husingaverengeki. .Kutsauka kunobvumirwa kwehurefu hwakagadziriswa i+20mm;Kureba kwekaviri kureba kuchabatanidzwawo muhuwandu hwakachekwa hwebhari, uye imwe neimwe yakachekwa ichava 5mm. Hurefu hwehurefu hwakatarwa kana hurefu hwehurefu hwakapetwa huchatsanangurwa muchibvumirano.

Zvinyorwa: rolling ¢8.0– 40mm× L; Kugadzira ¢40-150 - mm x L

Metallographic chimiro: yakachena titanium saizi yezviyo haisi pasi pegiredhi 5, TC4 titanium alloy inoenderana neA1-A9.

Uso: pasi dema, nzvimbo yakakwenenzverwa, yakakwenenzverwa (H11, H9, H8)

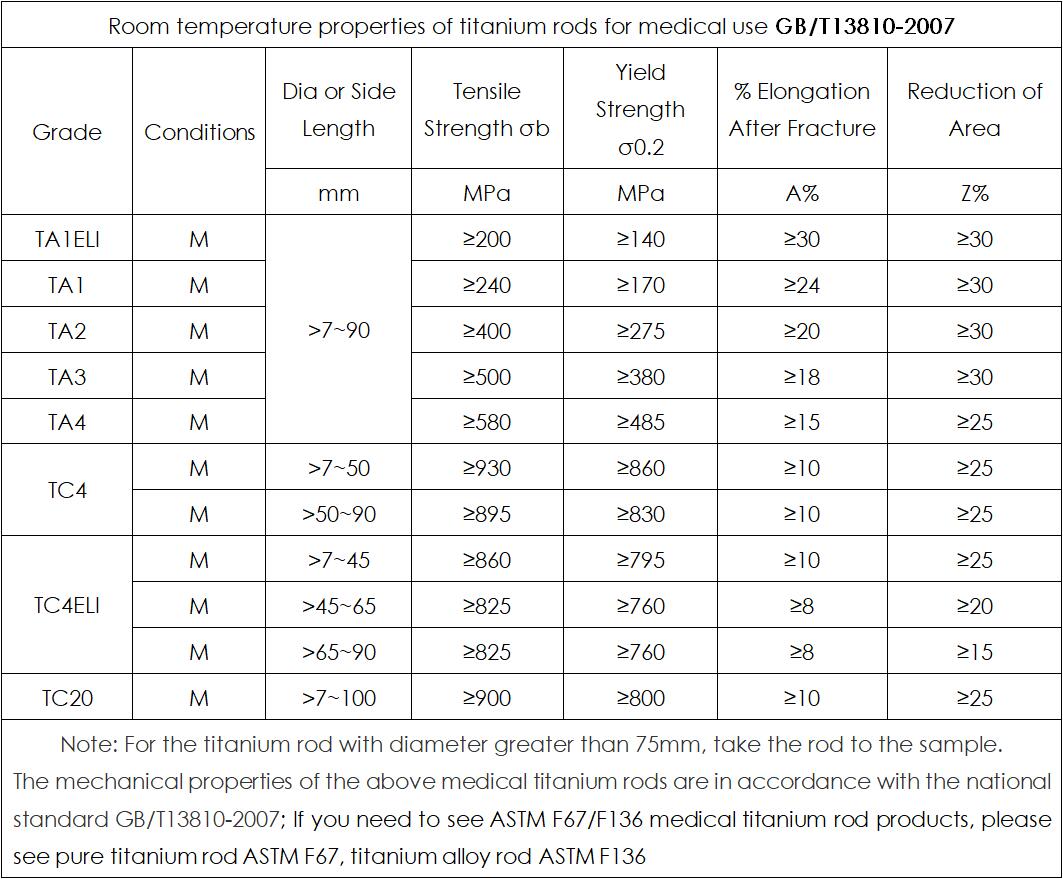

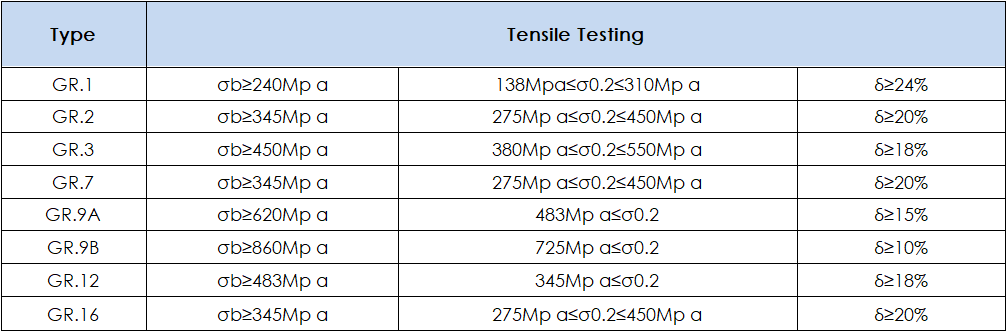

Kuita kwekurapa titanium tsvimbo (reference standard:GB/T13810-2007,ASTM F67/F136).

Isu tinogara tichigadzira uye kutumira kunze ASTM yakajairwa titanium bar uye Chinese Standard (GB) yakajairwa titanium bar, uye titanium bar yezvakabvumiranwa zvakaenzana.

Kuve tiri pakati pevagadziri vashoma vanogona kuona kutonga kwemhando pane yese yekugadzira maitiro, isu tinoshandisa yakasimba yemhando yekudzora nzira yese kubva pakunyungudutswa kwezvinhu zvetitanium sponge kusvika kune zvakapedzwa zvigadzirwa.

Kuve nemhando yepamusoro uye yekutevera uye sevhisi isina kunaka, tinotengesa zvigadzirwa zvinosanganisira yekurapa titanium bar, titanium polishing bar uye titanium alloy bar pasi rese. Isu tave mumwe wevatengesi vakuru uye vanotengesa kunze kwetitanium bar muChina.

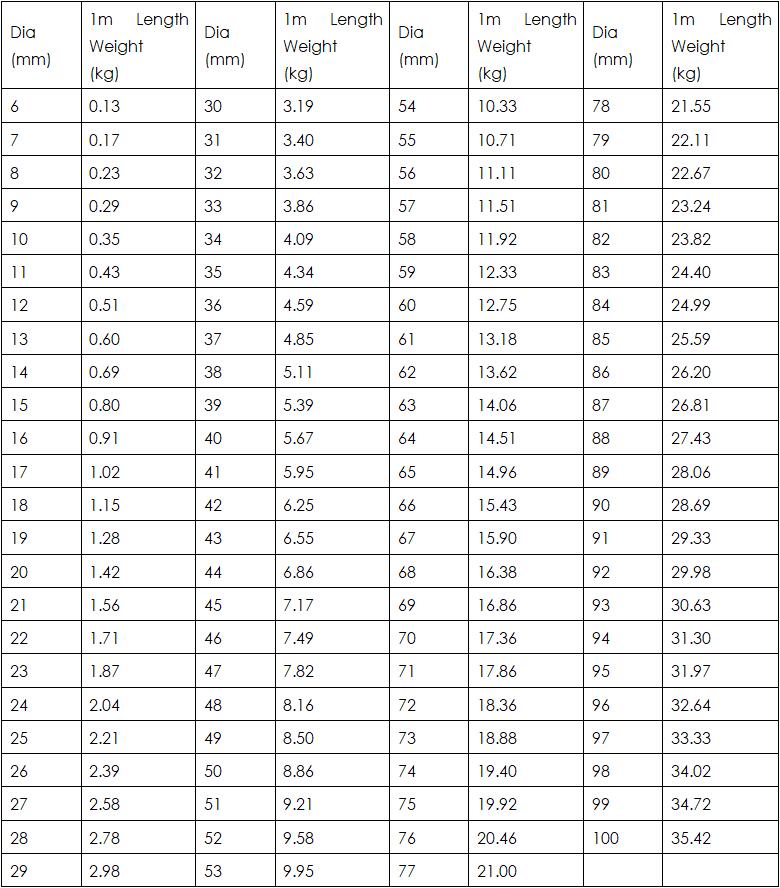

Saizi yemhando: Diameter 6-200mm x Max 6000mm

Tembiricha yekamuri zvivakwa zvetitanium tsvimbo yekushandiswa kwekurapa GB/T13810-2007:

Saizi Dzatakagadzira:

Dimensions, Tolerance uye Ovality Range:

Inowanikwa Material Chemical Composition

Inowanikwa Material Chemical Composition

Inspection test:

- NDT Test

- Ultrasonic Test

- Muedzo weLDP

- Ferroxyl Test

Kugadzirwa (Max uye Min huwandu hweOdha):Unlimited, maererano nehurongwa.

Nguva Yekutungamira:Nguva yekufambisa yakawanda mazuva makumi matatu. Nekudaro, zvinoenderana nehuwandu hweiyo odha zvinoenderana.

Zvekufambisa:Iyo yakajairika nzira yekufambisa ndeyeGungwa, neMhepo, ne Express, neChitima, iyo ichasarudzwa nevatengi.

Packing:

- Pombi inopera kuchengetedzwa nepurasitiki kana kadhibhodhi zvivharo.

- Zvese zvigadziriso zvinofanirwa kurongedzerwa kudzivirira magumo uye kutarisana.

- Zvimwe zvinhu zvese zvichange zvakazara nemafuro pads uye zvine chekuita nepurasitiki kurongedza uye makesi eplywood.

- Chero huni hunoshandiswa kurongedza hunofanirwa kuve hwakakodzera kudzivirira kusvibiswa nekusangana nemidziyo yekubata.

Isu tinotevera manejimendi ehutongi hwekuti "Hunhu hwakasarudzika, Mupi wepamusoro, Zita nderekutanga", uye tichagadzira nemoyo wose kubudirira nevatengi vese veManufactur standard China OEM Gadzirisa Datacom Medical Die Casting Copper Alloy Stainless Steel Alloy Steel Titanium Alloy Aluminium Alloy. Polymer Material Precision Machining, Nechokwadi tariro yekuvaka hukama hwekambani hunogara kwenguva refu newe uye isu tichaita kambani yedu yepamusoro munyaya yako.

Manufactur standardChina OEM Die Casting, Midhudhudhu Zvishandiso, Mutengi kugutsikana ndicho chinangwa chedu chekutanga. Basa redu nderekutevera hunhu hwepamusoro, tichifambira mberi. Tinokugamuchirai nemoyo wese kuti mufambire mberi makabatana nesu, uye kuvaka ramangwana rakanaka pamwe chete.