5 Nzira dzeKuvandudza Sheet Metal Parts

Sheet simbi yekugadzira seti inoshanda yekugadzira maitiro anoshandiswa kugadzira zvikamu kubva muzvidimbu zvidimbu zvesimbi. Sheet simbi inouya mumhando yezvigadzirwa uye ukobvu, uye inogona kushandiswa kugadzira zvikamu zvakaita semidziyo, zvakavharirwa, mabhuraketi, mapaneru uye chassis, nezvimwe.

Kuenzaniswa neCNC machining, kugadzirwa kwesimbi simbi kunotemerwa neyakaomesesa dhizaini dhizaini. Kune vamwe vashandi vatsva pakugadzira simbi, pamwe zvakaoma. Sheet simbi inofanirwa kubhenda uye kuchekwa neimwe nzira, uye yakakodzera chete kune zvimwe zvikamu uye zvigadzirwa.

Sezvineiwo, zvakakosha kuti udzidze mamwe misimboti yekugadzira sheet simbi usati washanda. Uchishandisa kugadzirwa kwesimbi simbi, matekiniki anogona kugadzira akasimba, anodhura zvikamu kubva kune akasiyana zvinhu. Zvikamu izvi zvinogona kushandiswa kwakasiyana siyana maindasitiri, kubva kune aerospace kusvika kumba mudziyo.

Ukobvu hwesimbi hunoshandiswa mukugadzira kazhinji huri pakati pe0.006 ne0.25 ”, nehukuru hunoenderana nezvakapihwa zvinhu uye kupera-kushandiswa kwechikamu.

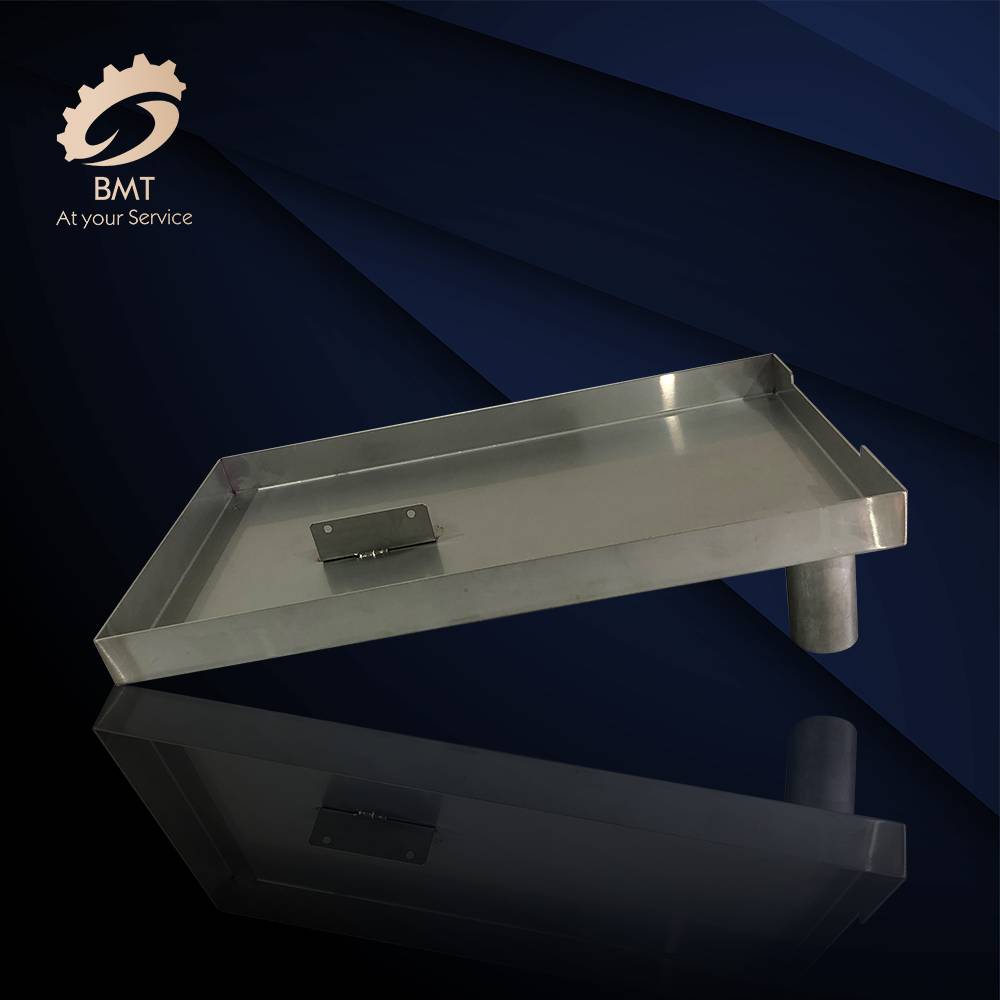

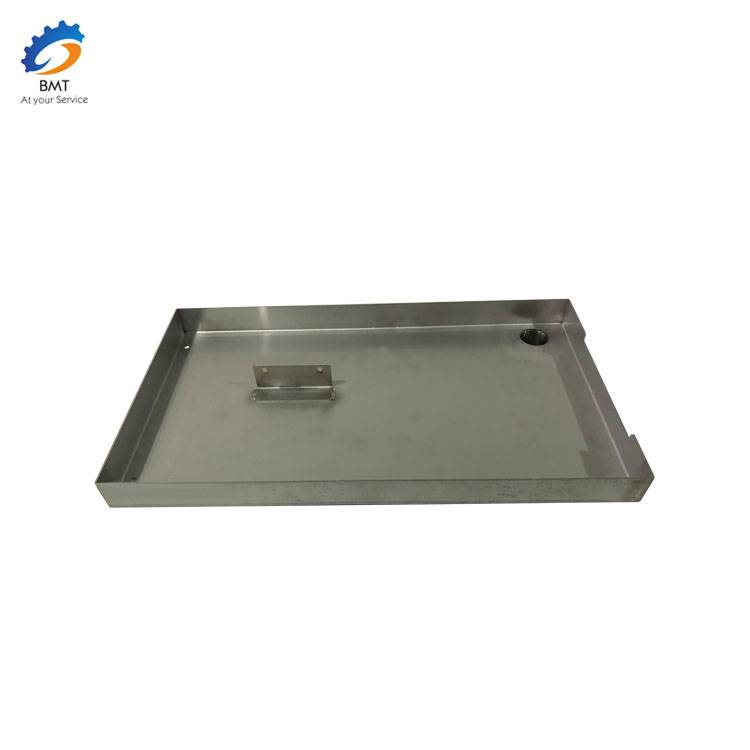

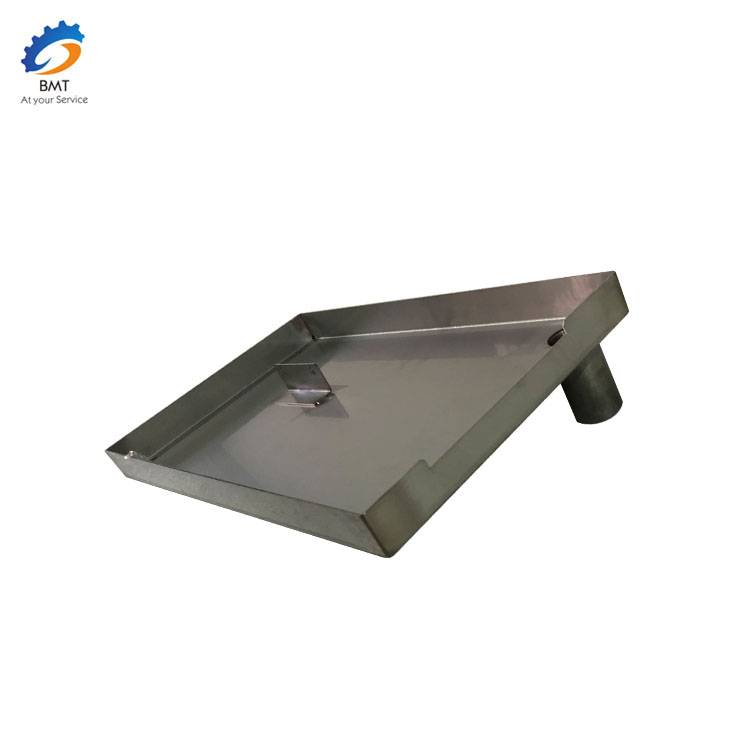

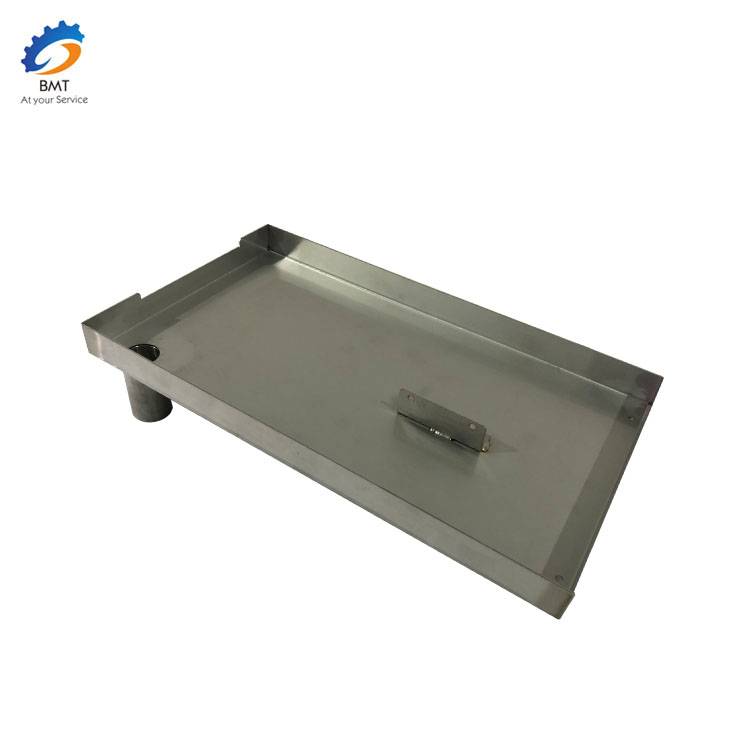

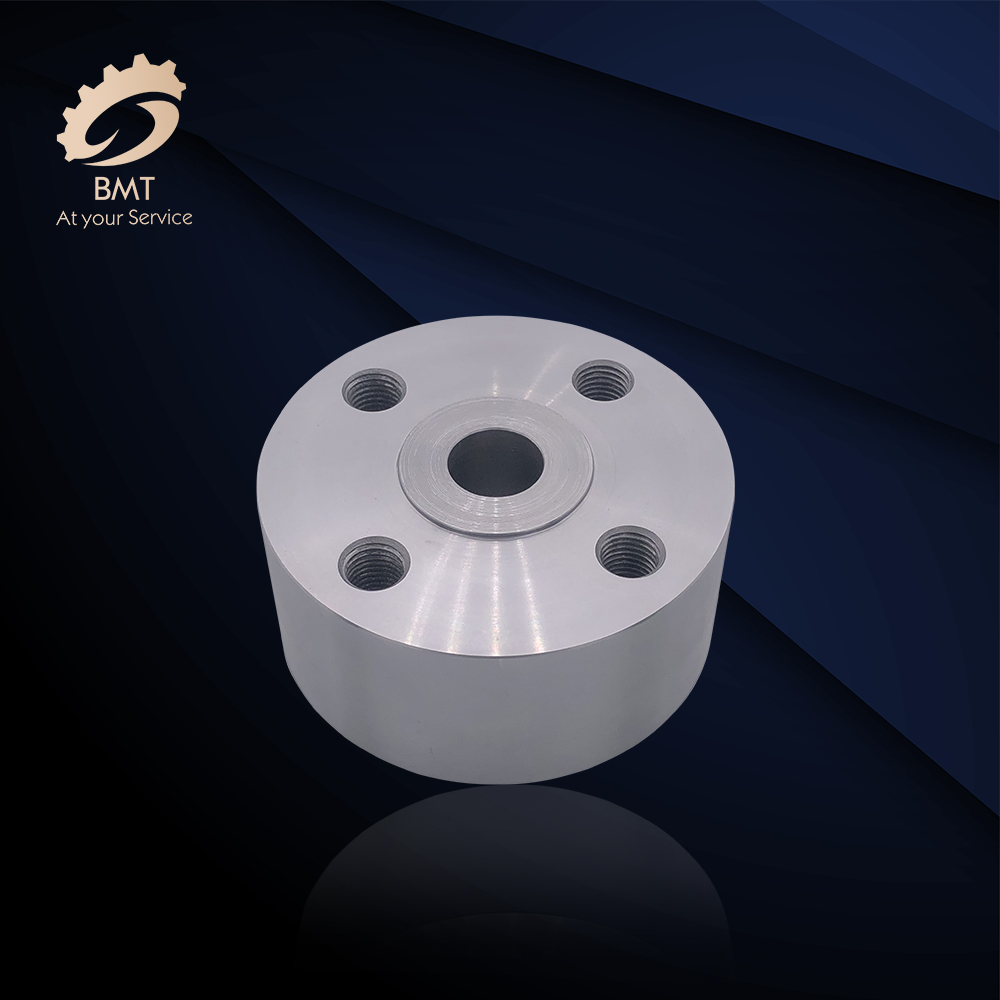

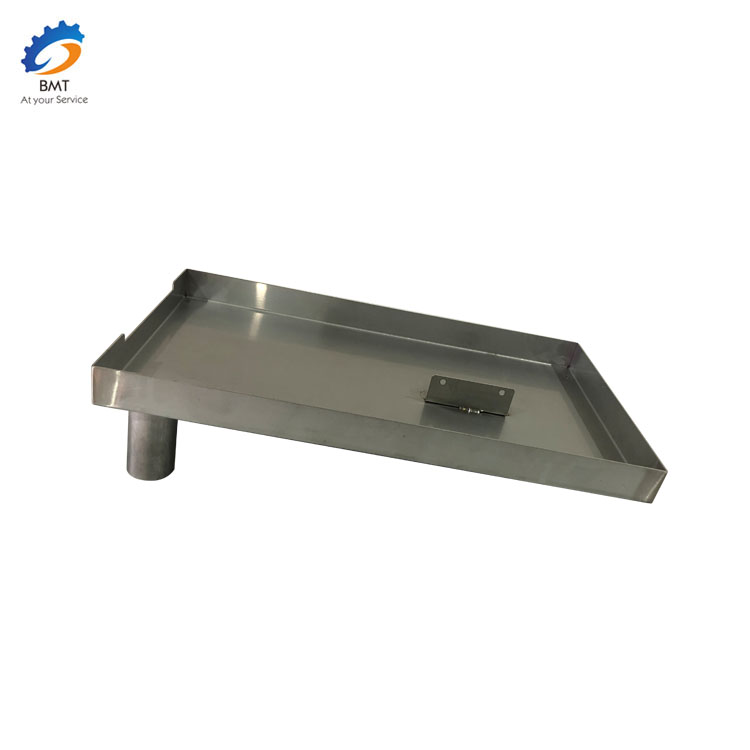

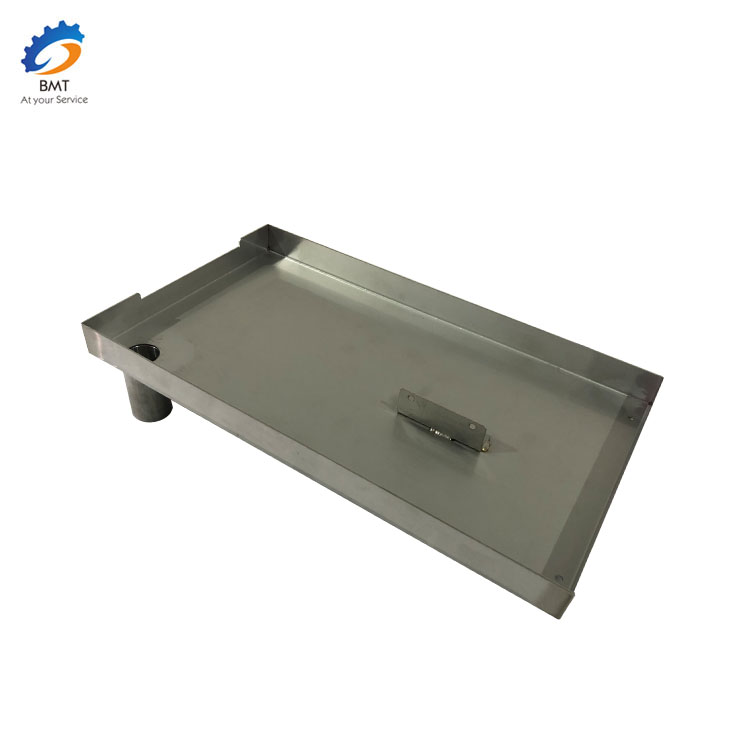

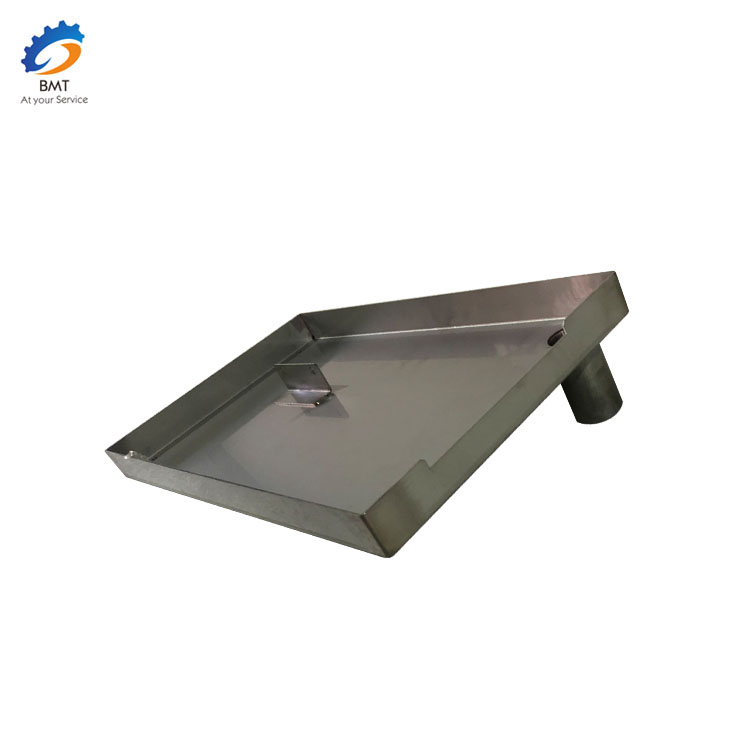

Product Description

Sheet metal fabrication yakasiyana pakati pemaitiro akasiyana-siyana ekugadzira. Nechikonzero ichi, iyo tekinoroji inogona kugadzira CNC machining zvikamu kana mold zvikamu, asi zvakaoma kugadzira mapepa esimbi zvikamu.

Nekucherechedza matipi matanhatu anotevera, vagadziri vanogona kugadzira mapepa esimbi zvikamu zvakasimba, zviri nyore kugadzira uye zvinoramba kuparara.

1. Makomba uye Slots

Sezvo mashizha ekugadzirwa kwesimbi anowanzoshandiswa kugadzira zvivharo, mabheji uye zvinhu zvakafanana, maburi uye slots zvinowanzodiwa kune screws, mabhoti kana zvikamu zvakapindirana. Makomba anowanzo gadzirwa ane punch uye anofa akaiswa muchitsikiro, achibvumira kuti chaiyo denderedzwa chimiro chichekwe kubva pashizha resimbi. Asi kana maburi asina kunyatsogadzirwa, buri racho rinogona kukanganisa kana kutoita kuti chikamu chacho pachacho chitsemuke.

Paunenge uchibaya maburi mupepa resimbi, mitemo mishoma inokosha inofanira kuteverwa. Makomba anofanira kunge ari 1/8” kubva kune chero madziro kana kumucheto uye anofanirwa kuparadzaniswa nekanenge ka6 pane ukobvu hwepepa resimbi. Uyezve, madhayamita emakomba ese uye slots anofanirwa kuenderana kana kudarika ukobvu hwesimbi pepa.

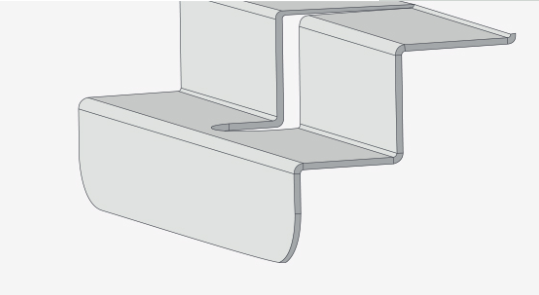

2. Hems

Hemming inzira yakanaka yekuita kuti simbi yesimbi ive yakachengeteka uye inoshanda. Isu tinoumba ese akavhurika uye akavharika hems. Kushivirira kwehemu kunoenderana neradius yemupendero, ukobvu hwezvinhu, uye zvinhu zviri pedyo nemupendero. Isu tinokurudzira kuti iyo shoma yemukati dhayamita yakaenzana nehupamhi hwezvinhu, uye hem yekudzoka kureba kwe6x zvinhu ukobvu.

Kana uchiwedzera hem kune chikamu chesimbi chesimbi, nhungamiro shoma dzinofanirwa kuteverwa kuti ive nechokwadi chekushanda kwakakwana. Kutanga, zvinenge nguva dzose zviri nani kudzivisa kuvhara hems. Yakavharwa hems ine njodzi yekukuvadza zvinhu nekuda kweyakanyanya kona yekubhenda, saka yakavhurika hems, iyo inosiya mukaha pakati pemativi maviri ehemu, zviri nani.

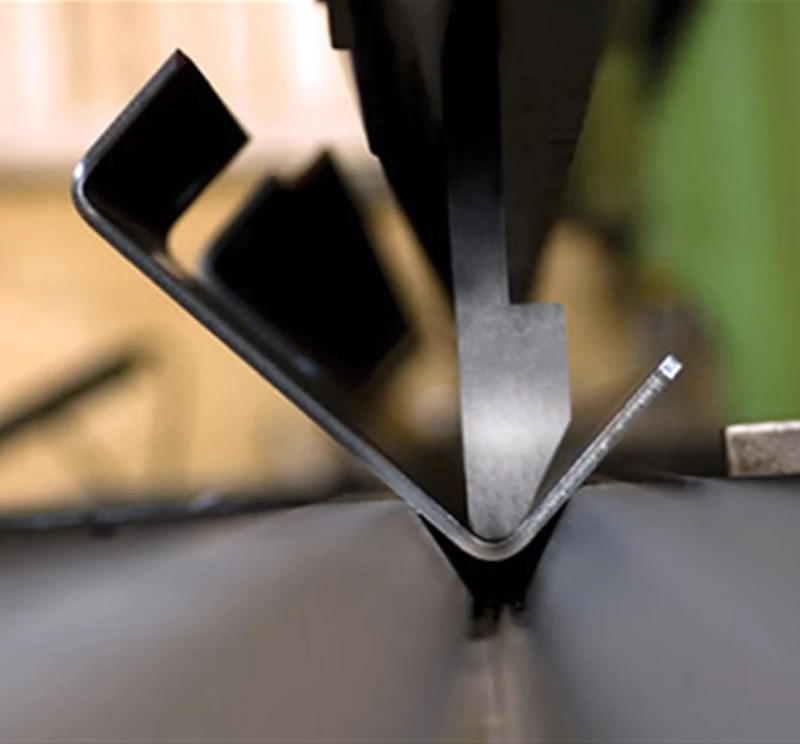

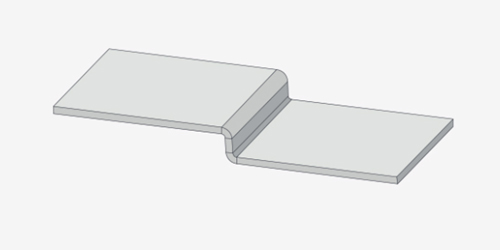

3. Mabhende

Kubhenda ndeimwe yeakanyanya kukosha ekuumba maitiro mukugadzira simbi simbi. Ichishandisa midziyo yakaita semabhureki nemichina yekutsikirira, fekitori inokwanisa kushandura simbi yesimbi kuita zvimiro zvitsva. Nekukotama, kuitira kuti tive nechokwadi chechokwadi uye kunyange kukotama, tinofanira kutevera mimwe mitemo, uye kuderedza mukana wekukuvadza kwezvinhu.

Mumwe mutemo wekutevera ndewekuti, kana uchigadzira chidimbu chesimbi chine mabhendi, iyo yemukati bend radius inofanirwa kuenderana kana kudarika ukobvu hwesimbi simbi kudzivirira deformation. Inokurudzirwa kushandisa radius yakafanana pamabhendi ese. Kuchengeta kuenderana mukubhenda kwakananga uye radius kunogona kubatsira kudzikisa mutengo, sezvo chikamu chisingazofanirwa kudzokororwa uye mudziyo wekupeta unogona kudzokorora maitiro akafanana.

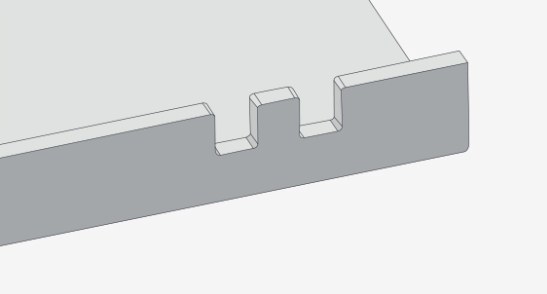

4. Notches uye Tabs

Notches uye ma tabo ndiwo akanyanya maficha eshizha simbi zvikamu zvinobatsira pakuwedzera screws kana fasteners kana kurodha zvikamu zvakawanda pamwechete. Notches madiki indents kumucheto kwechikamu, nepo ma tabo ari akabudikira maficha. Tabhu mune rimwe pepa resimbi chikamu chinowanzobatanidzwa kuti chikwane mune imwe notch yechimwe chikamu.

Kungofanana nemamwe mashezha esimbi maficha, kugadzira notches akakodzera uye ma tabo anodawo kutevedzera mimwe mitemo: notches anofanirwa kunge ari hupamhi hwechinhu kana 1mm, chero yakakura, uye haigone kupfuura kashanu paupamhi hwayo. Matebhu anofanira kunge ari kanokwana ka2 ukobvu hwezvinhu kana 3.2mm, chero yakakura, uye haigone kupfuudza kashanu kufara kwayo.

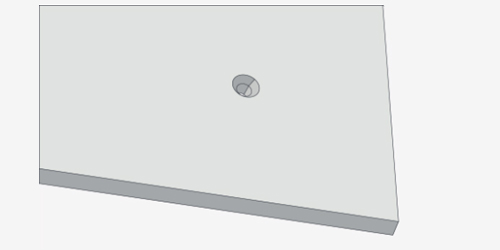

5. Offsets uye Countersinks

Countersinks inogona kugadzirwa neCNC Machining kana kuumbwa nemichina yakakosha. Kushivirira kweakaumba countersink yakakura dhayamita yakanyanya kuomarara, nekuti pamwe inoda kushandiswa nema screws kana fasteners. Offsets anoshandiswa kugadzira maprofiles ane Z mumashizha esimbi.

6. Kupedza

Zvichienderana nekushandiswa uye zvinhu zvakashandiswa, simbi yesimbi zvikamu zvinogona kupedzwa nekuputika kwebead, anodizing, plating, poda yekuputira uye mamwe maitiro akasiyana, kungave kwekuita basa kana kungovandudza kutaridzika kwechikamu.