Izvi Zvikamu-Matete-Walled Zvinogadzirwa Sei?

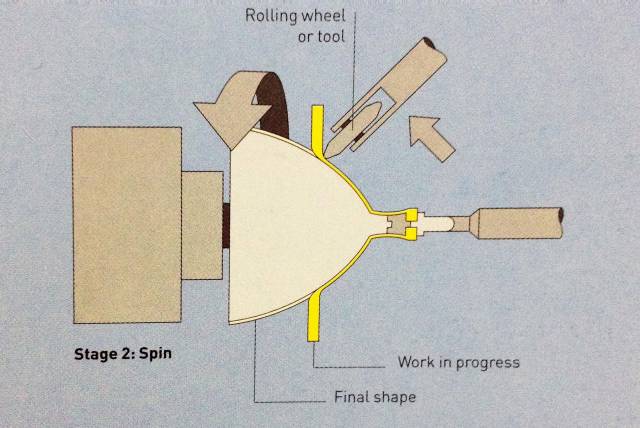

Metal spinning i symmetrical rotational forming process ye sheet simbi. Chikurunga chinotyaira chisina chinhu uye mold core kuti itenderere, uye ipapo vhiri rinotenderera rinoisa kumanikidza kune inotenderera isina chinhu. Nekuda kwekufamba kutenderera kweiyo shaft huru yemuchina wekutenderera uye kureba uye kuchinjika kwekufambisa kwechishandiso, iyi yenzvimbo yepurasitiki deformation inokura zvishoma nezvishoma kune iyo yese isina chinhu, nekudaro ichiwana akasiyana maumbirwo enhengo dzemuviri dzinotenderera.

Mari yekugadzira: mutengo wekuumbwa (yakaderera), mutengo wechidimbu chimwe chete (pakati)

Zvakajairika zvigadzirwa: fenicha, mwenje, aerospace, zvekufambisa, tableware, zvishongo, nezvimwe.

Goho rakakodzera: diki nepakati batch kugadzirwa

Surface Quality:

Hunhu hwepamusoro hunoenderana zvakanyanya nehunyanzvi hwemushandisi uye kumhanya kwekugadzira

Machining kumhanya: Pakati kusvika pakakwirira kugadzirwa kumhanya, zvichienderana nechikamu saizi, kuomarara uye sheet simbi ukobvu

Zvishandiso zvinoshanda:

Inokodzera kudziya simbi mashizha akadai sesimbi isina tsvina, ndarira, mhangura, aluminium, titanium, nezvimwe.

Kufunga Kwekugadzira:

1. Metal spinning inokodzera chete kugadzirwa kwezvikamu zvinotenderera, uye chimiro chakanyanya kunaka ndeyehemispherical thin-shell metal parts;

2. Kune zvikamu zvakaumbwa nesimbi inotenderera, mukati memukati unofanirwa kudzorwa mukati me2.5m.

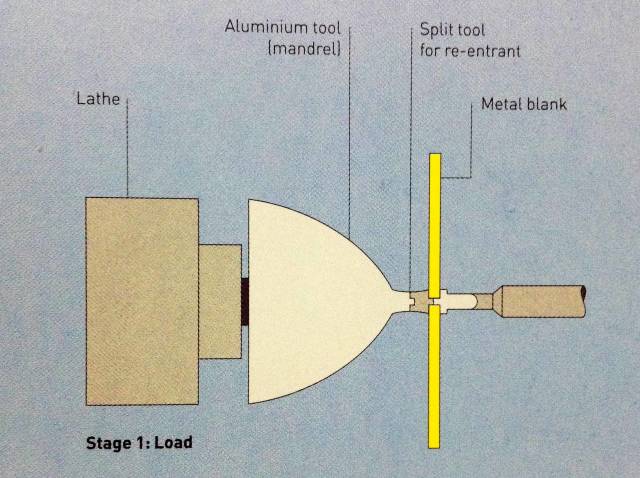

Danho 1: Gadzirisa yakachekwa yakatenderedzwa simbi pepa pamushini mandrel.

Danho rechipiri: Iyo mandrel inotyaira ndiro yesimbi yedenderedzwa kuti itenderere nekumhanya kukuru, uye chishandiso chine mumhanyi chinotanga kudzvanya pamusoro pesimbi kusvika ndiro yesimbi yanyatsokwana mukati memadziro emukati.

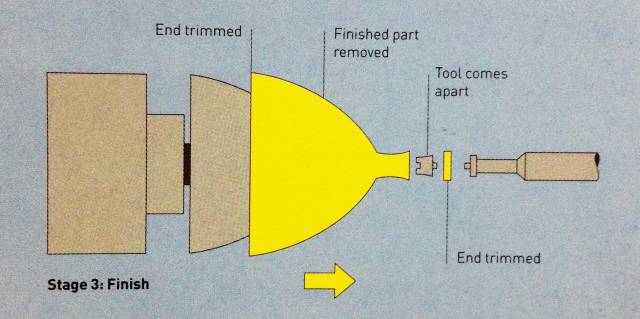

Danho rechitatu: Mushure mekuumbwa kwapera, iyo mandrel inobviswa uye kumusoro uye pasi pechikamu chacho zvakagurwa kuti zvigadziriswe.

Tumira meseji yako kwatiri:

-

Aluminium CNC Machining Zvikamu

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining Zvikamu

-

CNC Machina Zvikamu zveItari

-

CNC Machining Aluminium Zvikamu

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium uye Titanium Alloy Fittings

-

Titanium uye Titanium Alloy Forgings

-

Titanium uye Titanium Alloy Waya

-

Titanium Bars

-

Titanium Seamless Pipes / Tubes

-

Titanium Welded Pipes/Tubes