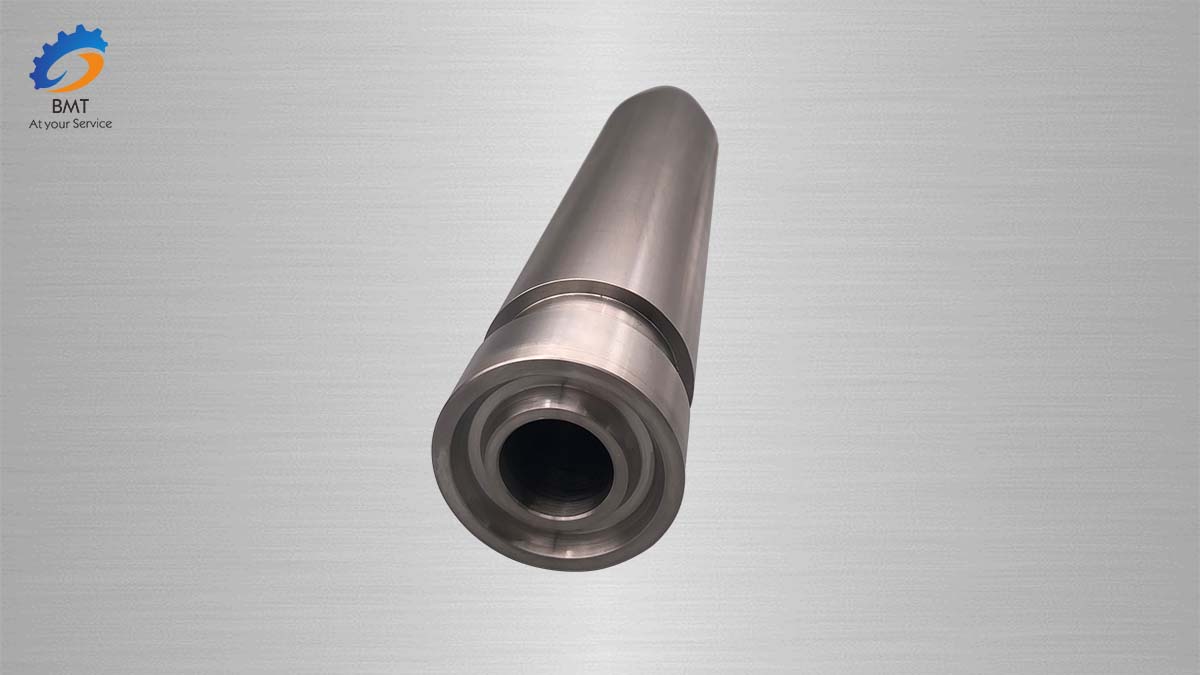

Titanium Alloy CNC Machining

Kudzvanya machining etitanium alloys yakanyanya kufanana nesimbi machining pane isiri-ferrous simbi uye alloys. Mazhinji magadzirirwo ma paramita etitanium alloys mukugadzira, vhoriyamu stamping uye sheet stamping ari padyo neaya ari mukugadzirisa simbi. Asi pane mamwe maficha akakosha anofanirwa kutariswa kana uchitsikirira uchishanda Chin uye Chin alloys.

Kunyangwe zvichiwanzo davirwa kuti hexagonal lattices iri mutitanium uye titanium alloys ishoma ductile kana yakaremara, nzira dzakasiyana dzekushanda dzekudhinda dzinoshandiswa kune dzimwe simbi dzakaumbwa dzakakodzerawo titanium alloys. Chiyero chegoho kusvika kune simba muganhu ndechimwe chezviratidzo zvinoratidza kana simbi inogona kumira plastiki deformation. Iyo yakakura iyi reshiyo, iyo yakaipisisa yepurasitiki yesimbi. Kune maindasitiri akachena titanium munzvimbo yakatonhora, chiyero i0.72-0.87, zvichienzaniswa ne0.6-0.65 yekabhoni simbi uye 0.4-0.5 yesimbi isina tsvina.

Ita vhoriyamu stamping, yemahara forging uye mamwe maoperation ane chekuita nekugadziriswa kwechikamu chikuru chemuchinjiko uye hukuru hukuru blanks munzvimbo inopisa (pamusoro peiyo = yS shanduko tembiricha). Tembiricha yemhando yekugadzira uye stamping yekudziya iri pakati pe850-1150°C. Alloys BT; M0, BT1-0, OT4~0 uye OT4-1 vane deformation yepurasitiki inogutsa munzvimbo yakatonhodzwa. Naizvozvo, zvikamu zvinogadzirwa neaya alloys zvinonyanya kugadzirwa nepakati annealed blanks pasina kudziyisa uye chidhindo. Kana iyo titanium alloy ichitonhora mupurasitiki yakaremara, zvisinei nemakemikari ayo uye magadzirirwo emagetsi, simba richavandudzwa zvakanyanya, uye plastiki ichaderedzwa zvinoenderana. Nechikonzero ichi, annealing kurapwa pakati pemaitiro kunofanirwa kuitwa.

Kupfeka kweiyo groove yekupinza mukugadzira kwetitanium alloys ndeyekupfeka kwenzvimbo kumashure uye kumberi munzira yekudzika kwekucheka, iyo inowanzo kukonzerwa neyakaomeswa layer yakasiiwa neyekare kugadzirisa. Iko kemikari kuita uye kupararira kwechishandiso uye chishandiso chekushanda pane tembiricha yekugadzira inopfuura 800 ° C zvakare chimwe chezvikonzero zvekuumbwa kwekupfeka kwegroove. Nokuti panguva yekugadzira, titanium molecules ye workpiece inounganidza pamberi pechidzitiro uye "yakasungirirwa" kune blade kumucheto pasi pekumanikidzwa kukuru uye kupisa kwepamusoro, kuumba muganhu wakavakwa. Kana iyo yakavakirwa mupendero inobvisa kubva kumucheto wekucheka, iyo carbide coating yekuisa inotorwa.

Nekuda kwekupikiswa kwekupisa kwetitanium, kutonhora kwakakosha mukuita machining. Chinangwa chekutonhodza ndechekuchengetedza chidimbu chekucheka uye chekushandisa kubva pakupisa. Shandisa end coolant kuitira optimum chip evacuation paunenge uchiita kugaya pamapfudzi pamwe chete nehomwe dzekugaya kumeso, homwe kana magrooves akazara. Paunenge uchicheka titanium simbi, machipisi ari nyore kunamatira kumucheto wekucheka, zvichiita kuti denderedzwa rinotevera rekucheka kwekucheka kutema machipisi zvakare, kazhinji kukonzeresa mutsara wekumucheto.

Imwe neimwe yekuisa mhango ine yayo inotonhorera gomba / jekiseni kugadzirisa nyaya iyi uye kuwedzera kunogara kumucheto kuita. Imwe mhinduro yakanaka ndeye threaded kutonhora maburi. Long edge milling cutters ane akawanda anoisa. Kuisa chinotonhodza pagomba rega rega zvinoda pombi yepamusoro uye kudzvanywa. Kune rimwe divi, inogona kuvhara maburi asina basa sezvinodiwa, nekudaro ichiwedzera kuyerera kumakomba anodiwa.

Tumira meseji yako kwatiri:

-

Aluminium CNC Machining Zvikamu

-

Aluminium Sheet Metal Fabrication

-

Axis High Precision CNC Machining Zvikamu

-

CNC Machina Zvikamu zveItari

-

CNC Machining Aluminium Zvikamu

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium uye Titanium Alloy Fittings

-

Titanium uye Titanium Alloy Forgings

-

Titanium uye Titanium Alloy Waya

-

Titanium Bars

-

Titanium Seamless Pipes / Tubes

-

Titanium Welded Pipes/Tubes